Touch-Sensitive Control Surfaces: The Next Thing in Medical Technology?

Close-Up on Technology: Injection Molding

Cost savings and cleanability are moving overmolded capacitive-sensing films from automotive consoles into medical equipment.

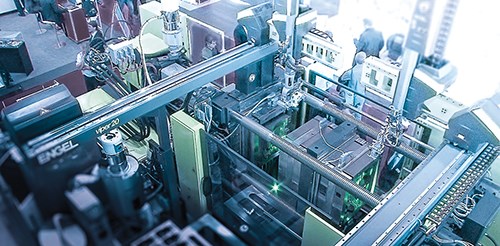

Capacitive sensing films encapsulated in injection molded parts, a technology promoted initially for automotive cockpit control consoles, is also presenting new opportunities in medical equipment. That’s the view at Engel, which has demonstrated the manufacturing concept at recent trade shows. For example, Engel (U.S. office in York, Pa.;) produced a prototype automotive center console in a complex molding cell at NPE 2012 in Orlando, Fla., and a “close-to-production” version of this application at Chinaplas 2013 in Guangzhou (see our NPE preview in March ’12).

The idea of “buttonless” touch-sensitive control surfaces offers manufacturing cost savings for automotive, along with a novel end-user experience. It offers an additional advantage for medical devices—continuously sealed, smooth, and easily cleanable control surfaces without any buttons, switches, or knobs to trap dirt, dust, and microbes.

At present, operator control surfaces on electronic medical equipment pose a risk in all environments, including sterile areas such as operating rooms. Membrane keyboards are one solution, but they tend to be less than robust in practice and therefore constitute an additional risk factor. Consequently, product designers are now turning to what Engel calls “multifunctional surfaces” based on capacitive electronics to give plastic surfaces functionality and electronic intelligence.

Such “intelligent interfaces” are achieved via capacitive sensors. The electric flux lines within an electric field can be changed by introducing a conductive object such as a fingertip. Capacitive sensors pick up these changes and respond with a voltage variation that can initiate a particular function. Since the electric field lines penetrate nonconductive solid bodies, the sensor effect operates from a distance through a thin surface layer such as a thermoplastic film or an operator’s gloves.

HOW IT’S DONE

The production technology for multifunctional services has been marketed in the automotive sphere by Engel and its technology partners (such as Magna Exterior & Interior Systems) under the name Sensitive Surface. It involves technologies employed for in-mold decorating (IMD) and Engel’s clearmelt process for overmolded liquid coatings.

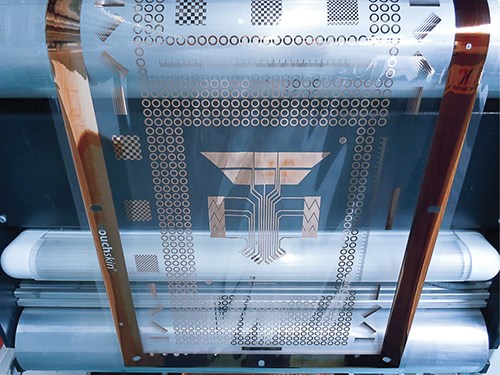

The foundation of the technology is plastic films, to which sensors and conducting paths are attached by printing, masking, and metalizing. The flexibility of printing makes it possible to position sensors almost anywhere, and the films can be formed to almost any shape.

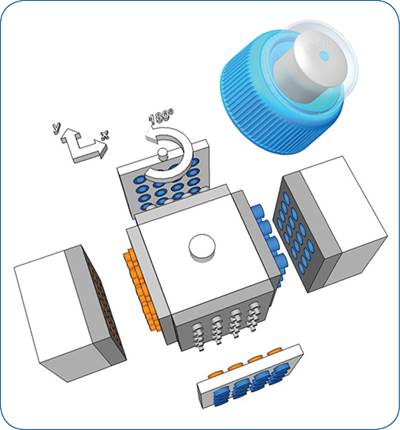

As demonstrated at NPE 2012 and Chinaplas 2013, printed and precut films are inserted by a robot into the first station of a horizontal rotating-cube mold mounted in an injection press. Next, the film is back-molded with a rigid support material (PC/ABS in the case of the automotive console). The mold rotates, and in station two, the front surface of the part is overmolded with a clear, two-component liquid urethane coating to create a glossy, self-healing surface. The PUR metering machine is located beside and integrated with the injection machine. A second robot removes the finished parts.

Whereas conventional manufacturing of control consoles often involves separate production and assembly of more than 100 small parts, the Sensitive Surface approach produces ready-to-install components in a single machine and process. “Taking the center consoles as an example, production costs are reduced by at least 30% if we look at the whole process,” says Michael Fischer, sales manager, Technologies, at Engel Austria.

“I think the fact that this technology addresses a whole set of requirements at a stroke represents a major opportunity for medical technology,” adds Christoph Lhota, v.p. of Engel’s medical business unit. “Firstly, we’re doing more to address stringent hygiene requirements. Secondly, we’re improving the ergonomics of medical engineering products. And thirdly, we’re drastically cutting production costs. Pressure on costs is rising in the medical engineering sector, too.”

Engel believes this technology offers potential in numerous high-volume medical devices, such as blood-sugar meters, insulin pumps, infusion pumps, and respiratory therapy devices. For the future, there’s also unexplored potential in household appliances.

Related Content

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreWisconsin Firms Unite in Battle Against Covid

Teel Plastics opened new plant in record time, partnering with AEC & Aqua Poly Equipment Co. to expand production of swab sticks to fight pandemic.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreABC Technologies to Acquire Windsor Mold Group Technologies

The Tier One automotive supplier with compounding and blowmolding machine capabilities adds the 50-yr-old molder and moldmaker.

Read MoreRead Next

Injection Molding: Speed, Automation & Integration

Hot buttons at the show will be multi-component molding, in-mold labeling/decorating (IML/IMD), in-mold assembly, medical molding, liquid silicone rubber (LSR), micro-molding, and high-speed packaging.

Read MoreInjection Molding: Speed, Automation & Integration

Hot buttons at the show will be multi-component molding, in-mold labeling/decorating (IML/IMD), in-mold assembly, medical molding, liquid silicone rubber (LSR), micro-molding, and high-speed packaging.

Read MoreInjection Molding: Speed, Automation & Integration

Hot buttons at the show will be multi-component molding, in-mold labeling/decorating (IML/IMD), in-mold assembly, medical molding, liquid silicone rubber (LSR), micro-molding, and high-speed packaging.

Read More

.png;maxWidth=300;quality=90)