Graphite-Filled PP Combines Flexibility and Conductivity

This new approach boosts mechanical properties while maintaining electrical conductivity.

This new approach boosts mechanical properties while maintaining electrical conductivity.

Germany’s Institute of Plastics Processing (IKV), along with Skilled Crafts at RWTH Aachen University, has been developing a new approach for the production of graphite-filled PP compounds, which thus far, appear to combine flexibility with high electrical conductivity.

The researchers claim the new, highly-filled thermoplastic compound boasts significant advantages over currently used materials, including reduced brittleness, longer service life in the fuel cell, and low reject rates.

The research project’s goal is to improve the compound’s mechanical properties compared to existing materials while maintaining the same electrical conductivity. Researchers first produced a blend of PP and an elastomer in order to boost the matrix material’s elasticity, and then incorporated a mixture of selected, electrically-conductive graphite fillers.

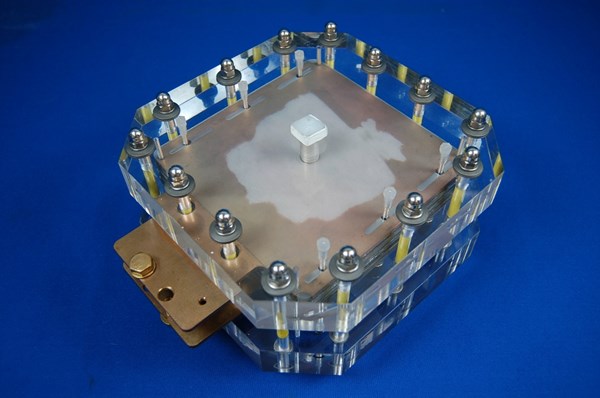

The researchers aimed to keep the filler content as low as possible while ensuring the necessary electrical conductivity for the particular applications. They demonstrated the potential usability of the new compounds by producing bipolar plates for fuel cells.

Together with various project partners, IKV is moving on with the development of a process in which the conductive part of the bipolar plate is compression molded from the highly-filled compounds, then overmolded by injection molding, and finally joined to form a composite part.

They stress that it is important that the bipolar plates be welded securely to one another to ensure that they are gas-tight, and also that process reliability and high efficiency are ensured. This joining technology is being systematically developed at IKV. The composite material is subsequently tested in the fuel cell under conditions likely to be encountered in practice.

This joint project is financed by the German Federal Ministry of Education and Research (BMBF) over a period of years. The other partners are Allod Werkstoff, Burgbenheim, Calorplast Warmetechnik, Krefeld, Eisenhuth, Osterode am Harz, Kessen Maschinebau, Essen bei Oldenburg, Leibniz Institute for Polymer Research, Dresden, and Protech in Pfullingen.

Related Content

-

The Effects of Temperature

The polymers we work with follow the same principles as the body: the hotter the environment becomes, the less performance we can expect.

-

The Strain Rate Effect

The rate of loading for a plastic material is a key component of how we perceive its performance.

-

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.