Launched in Germany in the spring of 2019, with global availability since the autumn of the same year, Arburg provided an update on the current and future functionality of its arburgXworld customer portal.

Available worldwide in 18 languages, arburgXworld’s various apps were grouped into four packages in the fall of 2020, according to the company. The free “Basic” package provides an overview of the machine fleet, service history and upcoming maintenance work. The “Premium” package, which comes with a fee, increases machine availability via extended digital machine files and video phone conferencing. “Premium Plus” provides access to calculation tools and detailed Arburg knowledge databases, and “Connect” features combined machine-related expansion options for digital networking.

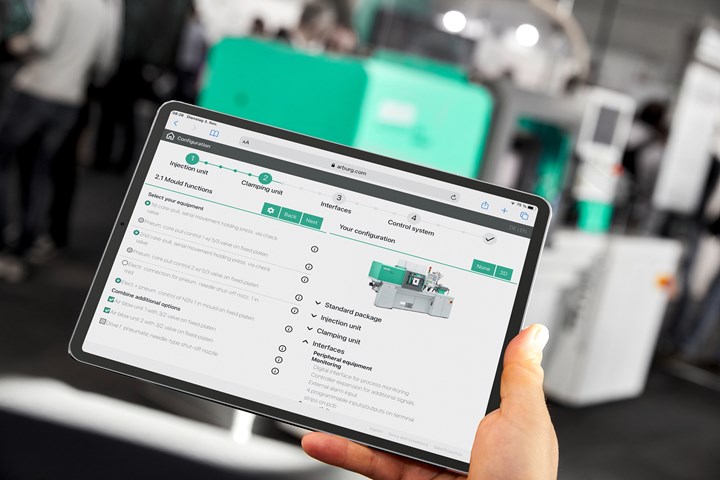

Using the free arburgXworld digital platform, molders can order and configure an Allrounder 270 S compact injection molding machine online.

Arburg reports that it now has tutorials for the various apps, explaining their functions. The Shop app, where users can order spare parts, can now be connected directly to a customer’s ERP system via an OCI (Open Catalog Interface). This allows purchasers to order spare parts as they usually would via their own ERP system with the order automatically transferred to the Arburg Shop. In addition to spare parts, customers can order and configure the Allrounder 270 S compact machine, as well as the Thermolift 100-3 dryer and conveyor, which was added in late October. Arburg says it will continue to expand this portfolio.

The Shop offers country-specific sales promotions, which are only available online through the app. Arburg also notes that anyone who registers for arburgXworld and uses the Arburg Remote Service receives a warranty extension for new machines of three or six months, depending on the country. In addition, customers purchasing a new machine will receive a voucher for retrofitting the 4.Service assistance package on two of their older injection molding machines manufactured from 2014 onwards at a special price.

A brand new feature is the possibility to integrate the additive manufacturing systems into the whole production landscape of a company via the customer portal when using Arburg’s Freeformer 3D printing machine platform.

Interest in Germany and Beyond

Benjamin Franz, Arburg’s manager of digital solutions, said that most of the portal’s users are in Germany, which is due in part to its initial roll-out in that country. Beyond Germany, Arburg reports curiosity in the U.S., France and Eastern Europe. Stephan Reich, department manager IT applications development, said top performing apps are the free Shop and MachineCenter programs. As mentioned, Shop allows Arburg customers to purchase parts and machinery, while MachineCenter provides transparency into a machine fleet via production-relevant information and documents. The representatives said premium applications such as SelfService, MachineFinder and the VirtualControl are also in demand.

Covid 19 Impact

As with literally everything else in 2020, Covid-19 has had an impact on the use of the arburgXworld digital platform. According to Franz, the pandemic and its limits on travel and in-person interactions, has prompted interest in the premium VirtualControl app. This program simulates a machine’s control on a PC or tablet. When working from a home office, installation technicians can use it to simulate and edit injection molding programs remotely and to perform troubleshooting. The data can then be transferred directly to the machine via the ALS host computer system or from a Flash memory card.

For companies avoiding business trips or on-site visits, Arburg now offers the option of remote machine acceptance. In this scenario, a sales rep goes through the specifications together with the customer, as the process is made more interactive via camera equipment so that all requirements can be visually checked item by item. At the end, customers receive a detailed report with additional visual documentation. In addition to being pandemic safe, Arburg notes this sales method is both time and cost efficient and represents a viable option for the future.

Related Content

An Automation 'First' for Non-Servo-Eject Trim Presses

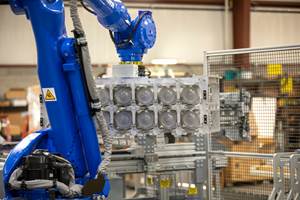

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.

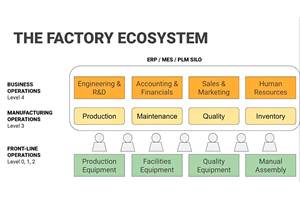

Read MoreWhat Comes After MES? It’s Already Here

If you’re not sure what the initials M-E-S mean, or whether that’s something your business needs, it may be time to look beyond MES to the next generation of manufacturing connectivity.

Read MoreEnsuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

Read MoreHow Machine Monitoring Delivers Tangible Results

Much more has been said than done about reaping the benefits of data driven manufacturing among plastics processors. Good technology is essential, but change management is the most difficult part of the process. Here’s how to think about both.

Read MoreRead Next

Injection Molding: Free Customer Portal Offers Parts Ordering & Service Assistance

AburgXworld portal offers both free and fee-based apps for a wide range of tasks.

Read MoreInjection Molding: Machine Series Can Be Configured, Ordered Online

Arburg’s Allrounder 270 S boasts a smaller footprint and 25% lower cost, with online configuration and ordering said to shorten delivery time.

Read MoreK 2019 Preview: Injection Molding Goes for the ‘Green’

‘Circular Economy’ joins Industry 4.0 as common themes of injection molding exhibits in Düsseldorf.

Read More