Machine-Side and Central Chiller Lines, Industry 4.0 Controls to Launch

Frigel will use K 2022 to showcase a number of developments in process cooling, including new and expanded lines of central and machine-side chillers, as well as advanced control platforms.

Frigel will highlight its MiND 2.0 platform, which it describe as an evolution of its Industry 4.0 offering. The company says MiND 2.0 provides a supervision and maintenance tool for all Frigel equipment and accessories, including central and machine-side chillers, monitoring and managing all working parameters and events, while tracking performance and energy consumption through a multifunctional user interface that can be accessed locally and remotely.

Frigel has updated its chiller controller launched in 2015, with the planned introduction of 3PR 4.0 at K 2022.

Photo Credit: Frigel

Frigel has also updated its 3PR control, originally released in 2015. Designed to control its central cooling systems, Frigel says the new 3PR 4.0 platform allows processors to supervise and manage the entire cooling system from a single point. All the connected central system components are controlled via a unique control panel that has been designed specifically for Frigel systems. 3PR 4.0 is available in two versions—Lite and Premium—depending on the size of the system and the equipment to control. 3PR 4.0 also features full native connectivity to MiND, and it features a new HMI that lets users visualize equipment and process diagrams for connected equipment, including dashboards for main parameters, performance graphs and alarm management and history.

For press-side mold temperature control unit (TCU), Frigel is introducing the patent-pending Microgel Syncro. “Syncro” here is short for synchronized, and Frigel says the unit is digitally synchronized with the molding process, such that cold water is only supplied during the cooling phase, which greatly reduces the cooling time, while it also keeps the mold cavities hot during the injection phase. Frigel says this has helped the Microgel Syncro achieve cycle time reductions up to 40%. The complete Microgel Syncro product line features more than 10 models, with cooling capacities from 16 to 56 kW and heating capacities from 12 to 24 kW.

Microgel RS TCUs for injection molding are available in single- (RSM) and dual-zone (RSD) designs.

Photo Credit: Frigel

Frigel will also release the full range of its Microgel RS TCUs for injection molding. These single- (RSM) and dual-zone (RSD) machine-side units are designed for molding throughputs ranging from 10 to 240 kg/hr (20 to 530 lb/hr). Advancements in the new Microgel RS range include greater temperature accuracy over the entire full range from -5 to 90 C, as well as higher pumping performance and overall energy efficiency. Frigel says the RS range features additional configurations specifically designed for packaging (RSP) and extrusion (RSB). Flow meters, VFDs and return/remote temperature sensors are available. The new user interface offers full connectivity via the MiND platform.

Frigel’s high-performance Turbogel RB TCU line will be shown with an upgraded digital control to allow full connectivity with the company’s MiND platform, as well as other Industry 4.0 architectures. Frigel says various equipment configurations are available including VFDs, increased heating capacities and SSR control. In addition, higher temperature ranges and customized pump selections are available based on mold-specific application data.

Frigel will also show advances in its TDK direct-injection pressurized-water TCUs. These range up to 120 C (248 F) for technical molding applications in markets like automotive and medical. Flow meter options are available, as is connectivity to Frigel’s MiND platform or other Industry 4.0 architectures, enabling process monitoring and data recording.

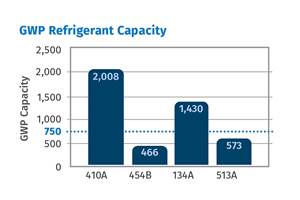

In central chilling, Frigel is completing its 3F series of industrial modular chillers with a new, integral air-cooled package chiller line: the 3FA range. Frigel says these offer high efficiency screw technology with a VFD option; a microchannel high-performance condenser; electronically commutated (EC) fans for increased part-load efficiency and low ambient temperature control; a low global warming potential (GWP) refrigerant option (R-513a); wide process and ambient temperature operating ranges; modular design with factory pre-engineered piping configuration; and a recirculation water package option.

The 3FA reportedly has a minimal indoor equipment footprint, and while ideal in moderate climates, it can function well in cold climates when water glycol mixtures are possible for use. The Ecodry Dry range and the Aquagel pump and tank packages complete a fully integrated system solution for maximum cooling performance and minimal environmental impact. The 3FA range features seven models and three different versions with capacities ranging from 170 to 600 kW for centralized expandable systems with capacities up to 3500 kW.

The 3FA range completes Frigel’s 3F series of industrial modular chillers with a new, integral air-cooled package chiller line.

Photo Credit: Frigel

Frigel will also expand its Adiabatic product family line, introducing the Ecodry MDK range. The company says this line is designed for flexible configuration of modular adiabatic chillers for small to large plastic processors. The MDK takes advantage of some of the technological advances already introduced in the LDK range, including new efficient PADs, next-generation EC fans and a modular design. Frigel says the MDK’s Coolpad high-efficiency humidification system and new EC fans combine with a more effective dry cooler to achieve a new level of compactness and power. The Ecodry MDK is designed to integrate into existing Ecodry 3DK systems.

Related Content

Low-Flow Indicator Has Optional Flow Regulator

Burger & Brown's Smartflow Low Flow indicator monitors critical, restricted cooling paths such as mold cooling lines with bubblers or baffles.

Read MoreCooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

Read MoreTemperature Control: What You Need to Know to Comply With New Cooling-Fluid Regs

Beginning the first of this year, 12 states are following EPA bans on potentially damaging cooling fluids. Chiller suppliers have adjusted equipment designs to accommodate the new regulations. Here’s what all this means to processors.

Read MoreHow to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

Read MoreRead Next

Frigel’s New Thai Production Plant Nearly Complete

Process cooling technology supplier Frigel, Scandicci, Italy, has nearly completed a new manufacturing site in Thailand that will boost its global production footprint by more than 50%.

Read MoreHeating/Cooling: Variotherm & Economy TCUs Debut at Fakuma

Active variotherm hot/cold circulators are new for Frigel, which also brought out an economical pressurized-water TCU built in India.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More