In-Mold Decorating

K 2007 Injection Molding: Lots of New Machine Choices For Exotic to Everyday Molding

If you were looking for a new machine to mold micro- or mega-sized parts, multiple materials, long fibers, high-speed/high-cavitation packaging, exotic multi-material combinations with compounding on the machine, or just a cost-effective press for general-purpose use—K 2007 had it all.

Read MoreAuto Glazing: Film, Coinjection & Coating Technologies Advance

Hard-surfacing options for molded plastic glazing now include plasma instead of wet coatings–and replacing coatings altogether with in-mold film lamination or multi-layer coinjection.

Read MoreWhat's New at the Show in INJECTION MOLDING

At the big “K” Show next month, top billing goes to new all-electric machines aimed at every segment of the market, from general-purpose to high-end.

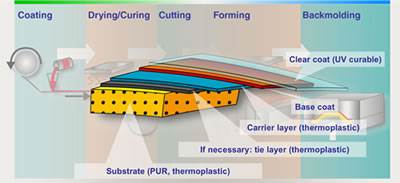

Read MoreDual-Cure PUR Coatings Boost Performance Of In-Mold Decorating Films

A new version of in-mold decorating technology, developed initially for exterior auto body components, uses dual-cure coating technology to provide a paint film that is both stretchable for good thermoformability and also provides the high gloss and durability of conventional paints.

Read MoreThermoforming: Ready for In-Mold Labeling?

After several fits and starts over the last decade, thermoforming IML appears ready for prime time, thanks to improvements in output and labeling technology. For now, the action is mostly in European packaging.

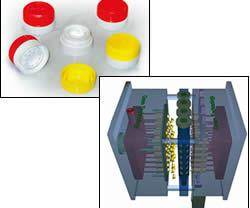

Read MoreIn-Mold Assembly: The New Frontier for Multi-Shot Molding

The drive to eliminate secondary operations is pushing multi-shot injection molding a step farther—toward assembling separate components in the tool via snap-fits, welding, and co-molding of incompatible materials.

Read MoreRigid Packaging Goes Lighter, Thinner With Microcellular Foam

Molding higher volumes of a rigid thin-wall part typically means going to a larger press for increased injection and clamping capacity.

Read MoreLearning to Master In-Mold Labeling

As in-mold labeling, or IML, attracts a growing following among U.S. molders, some are finding that mastering a complex new technology is no small task.

Read MoreThermoformer Offers Help With IMD

Hy-tech Forming Systems (USA) Inc., Phoenix, Ariz., is a specialist in close-tolerance forming of printed film using hydroforming, a technology utilizing fluid pressure behind a diaphragm to force heated film into a mold.

Read MoreNPE 2006 News Wrap-Up: Injection Molding

Advances in electric drive technology were evident in nearly every injection machine builder’s booth in Chicago.

Read More