Thermoforming: Ready for In-Mold Labeling?

After several fits and starts over the last decade, thermoforming IML appears ready for prime time, thanks to improvements in output and labeling technology. For now, the action is mostly in European packaging.

Machine builders and automation specialists have been on a roller-coaster ride when it comes to development of in-mold labeling (IML) for thermoformed products. Unlike injection molding, which sped into IML like a rocket, thermoforming has been forced to address several important limitations in machinery and labeling technology that have restricted IML’s penetration into packaging since the early 1990s.

Despite limited commercial success to date, observers point to skyrocketing interest, mostly in Europe. And many believe that recent advances in productivity and lower costs for labeling have finally made the process cost-effective. “The process is ready to go, the market is confident, and more people are interested in introducing new products with IML,” claims Bernd Bruckert , director of sales and marketing for automation specialist Hekuma GmbH, a German robotics firm experienced in IML for injection molding.

There is some talk that a totally new machine design may be required to satisfy output demands, particularly in the U.S. But the conventional wisdom is that IML for thermoforming will ultimately win broad commercial success due to its ability to bring high-quality design, flexible product changes, and cost savings.

IML allows manufacturers to save time and money by integrating the labeling process directly into the forming process. This one-step approach offers big advantages over traditional decorating methods like pad and offset printing, shrink-sleeve labels, and pressure-sensitive and glued-on labels, all of which require secondary operations.

Because a molded-in plastic label becomes part of the product, contributing stiffness and strength, thermoformers can save up to 20% in resin cost by lightweighting containers with IML, say industry sources. If the label is of the same material as the container, IML also offers recycling advantages over paper labels.

Hurdles overcome

Slow and steady is the best way to describe development efforts since Germany’s Illig and Gabler introduced the first thermoforming IML systems in the early 1990s (see Learn More box). Until that time, IML had been limited to form/fill/seal machines with a secondary trim station. Italy’s OMV Group was another pioneer, introducing an IML system at the K ’98 show in Dusseldorf. Kent Johansson, president of OMV-USA, says output rates of early IML systems fell far short of what was needed to meet manufacturing demands, especially for the North American market.

Another obstacle was that the labels used for injection molding IML offered poor adhesion in thermoforming due to the cooler temperature of the sheet and much lower pressures involved. Coextruded multilayer PP labels with a layer of low-melting PP have solved the adhesion problem, but at somewhat higher cost.

Another problem has been the difficulty in removing air bubbles trapped between the label and package wall, causing unsightly blisters. Perforated labels are now available with invisibly small holes to let air escape.

Finally, standard OPP labels have presented problems of excessive shrinkage due to the heat encountered in IML.

A leading European maker of labels for injection molding IML has developed an innovative product for thermoformers that claims to solve shrinkage, blistering, and adhesion problems. P’Auer AG in Switzerland came up with a standard PP label made via a patented relief embossing process. The embossing is said to facilitate more even shrinkage and allows air to escape between the package wall and label. The “bumps” created by the embossing also provide better melting and adhesion compared to a flat surface, the company claims.

In Europe, where most of the IML activity is occurring, rectangular containers for ice cream and ready meals are the primary application because IML is considered faster and less costly than offset printing. Meanwhile, round containers, which are more popular in the U.S., are still more economically decorated by offset printing.

Besides differing popularity of particular package shapes, global penetration of thermoforming IML also will hinge on the degree of exploitation of IML’s potential for eye-catching consumer appeal. Compared with the U.S., European packagers are said to place a greater emphasis on colorful graphics and decoration for product differentiation. Observers say this has been a driving force in the explosion of injection molding IML—where Europe also leads the U.S.—in place of printed thermoformed containers.

IML systems arrive

Most of the major machine suppliers offering IML systems say the technology is here and ready for market. But even with the current improvements in output, there still remains a gap versus the productivity of conventional thermoforming. IML slows down the process, reducing output to 20 cycles/min vs. 40 cycles/min for standard thermoforming of PP cups. “At a time when everyone wants faster and faster, this is the big disadvantage of IML,” says Erwin Wabnig, sales director for packaging at Kiefel.

Nearly all the machine systems for IML incorporate tilting-mold technology, which provides greater accessibility and easier label placement. Kiefel’s Thermorunner KTR 4 is a tilt-mold machine that is incorporated into an IML system developed with Hekuma and Austrian tooling specialist Mould & Matic. Kiefel’s Wabnig says the tilt-mold system is currently the best method available for IML, but his company is investigating totally new machine designs to boost output.

Developed for a line of dairy products in Europe, the KTR 4 is a standard cup-forming machine with control modifications that permit a 0.5-sec mold-open time for label infeed. A four-cavity system that was shown at K 2004 has been upgraded to eight or 12 cavities running at 15 to 20 cycles/min. The eight-cavity unit can produce PP containers up to 2.5-L while the 12-cavity can make containers weighing up to 500 g.

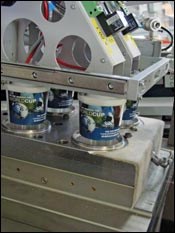

The IML system utilizes Hekuma’s Push-and-Wind label preparation system. The preformed labels are grasped by a robot, electrostatically charged, and then robotically inserted into the mold. The 75-micron-thick PP label costs slightly more than similar labels for injection molding IML, says Hekuma’s Bruckert. Thinner labels down to 57 microns are coming, and Hekuma has also successfully tested one 40 microns thick.

A new twist on Hekuma’s IML system is the integration of in-mold RFID tagging technology to create packaging capable of holding supply-chain data for shipping, inventory, and freshness tracking. The RFID-IML technology, demonstrated at NPE 2006, consists of a copper printed circuit that is attached to a PET film. Hekuma has proven a manual labeling system and is developing an automatic system. Hekuma admits the RFID tag is still too expensivefor low-value products, costinganywhere between 0.70 and 2 euros ($0.90 to $2.60) apiece.

Automation is a key

Another tilt-mold option for IML comes from Germany’s Gabler (represented here by Lyle Industries) in a development project with toolmaker Marbach and Systec Komplettsysteme GmbH, a leading supplier of injection molding IML automation. Gabler’s standard M93 thermoformer was adapted for IML and features a servo-driven mold table that tilts 90° for easy label placement. The Zapod automation system from Systec consists of a linear-drive robot with two swivel heads that approach the mold from opposite sides, placing the label in the cavity and then later removing the part.

Gabler’s 12-cavity IML system was designed for a U.S. manufacturer to make an oval 1.5-L ice-cream container. It runs 14 cycles/min and can produce 10,000 containers/hr. The cycle rate is said to be approximately 15% lower than standard forming units. The developmental system has yet to be commercialized.

Illig has been a one-stop source for IML systems and has steadily refined and upgraded its systems since introducing a cut-in-place IML forming system in 1994. That system was used to make margarine tubs in Europe. Since then the company has developed a form/fill/seal system called the FSL 70, which has served as a foundation for the current generation of IML technology. “The FFS line gave us a platform to learn more about the IML portion so we could adapt it to trim-and-place systems,” says Stefan Deuschle, general manager of Illig LP in the U.S.

At Illig’s German headquarters, a 16-cavity FSL 70 line produces 200-cc yogurt containers for a European dairy company. The containers are formed and labeled but not filled.

Illig recently came out with a new IML system based on its RDM K line of mechanically driven cut-in-place formers. Label insertion is made easier by the tilting tool that is standard on the RDM K line.

An important new feature is a two-axis robot arm that preforms the labels and inserts them into the cavities. The labeling station removes labels from stack magazines using vacuum cups. The robot arm has transfer heads shaped like forming plugs, which hold the labels by means of vacuum holes. The labels are placed on the plugs and the robot inserts the preformed labels into the cavities. Illig declined to say specifically how the plug picks up the label.

The first system was sold to an Austrian company for production of round, 95-mm-diam. PS containers. The 12-cavity unit runs up to 20 cycles/min and produces 19,200 containers/hr. The system uses Illig’s RDM 70K former with a forming area of 680 x 280 mm. The IML system can do both round and rectangular containers. Key applications include ice cream and margarine. A standard 0.070-mm (70-micron) OPP label for injection molding IML is currently used and thinner labels are being developed, says Deuschle.

IML minus a tilting mold

OMV-USA is another one-stop source for IML forming machinery and handling automation. The company has made major productivity improvements since showing a developmental system with an 11-sec cycle time at K ’98. Since then, OMV has converted its F25 continuous in-line former to IML and sold three systems to a German dairy company. The seven-cavity systems manufacture 1-lb margarine containers and also can produce 1.5-L ice-cream containers. OMV is finalizing a deal to sell its fourth unit to another European packaging company.

OMV’s system is unique because it lacks a tilt-mold feature. “We have a patented linear robotic system for removal of the product, so there’s no need for a tilting mold,” says OMV’s Johansson. A robot arm picks up a label and transfers it to a male forming plug that holds the labels. The plugs are inserted into the cavities. The same robot then removes the finished product. A 0.05- to 0.07-mm (50- to 70-micron), multilayer PP label features a layer of low-melting PP for adhesion.

Johansson maintains that a production rate of 12 cycles/min with maximum cavitation is adequate for small to medium-size European markets for rectangular containers. He also cites strong interest in IML margarine containers in South America, particularly in Brazil. To meet higher output requirements in North America, OMV has modified its larger E76 shuttle machine for IML. The 18-cavity system can produce rectangular products at 17 to 18 cycles/min. A key target in the U.S. is ice-cream containers.

OMV has an unusual development project, whereby labels for the high-output machine would be cut from rollstock in-line with forming. Such a system would eliminate label handling and reduce cost.

Dual-mold option

Another new entry in IML uses a dual-mold configuration instead of a tilting mold. GN Thermoforming Equipment in Canada collaborated with a European automation specialist to develop its first IML system by adapting its GN1914 DM dual-mold forming machine. “The dual-mold system allows removal of the finished part and placement of the label in one mold while a part is being formed in the other mold,” explains Jerome Romkey, director of marketing.

The dual-mold system runs at about 20 cycles/min. The first IML unit was sold to a European company to produce APET clamshell trays. A heat-sensitive PP label promotes adhesion to the tray. The IML system is expected to be in production by June.

Meanwhile, a leading European processor has done its own R&D to test the viability of IML for thermoforming. RPC Bebo Plastik GmbH, Bremervoerde, Germany, a manufacturer of injection molded IML products, has married Hekuma’s IML automation system with Illig’s RDM 70K tilt-mold machine. On a 12-cavity system, RPC has produced 500-g rectangular PP margarine containers. The system could also be used to produce PS containers in sizes up to 2-L for ice cream and other dairy products, says Juergen Merbach, manager of product and process development. The company is talking with several potential European partners.

A good example of the growing interest in IML in thermoforming is a new package proposed by Paris-based Danone. The yogurt giant is seeking proposals for a 1.5-L rectangular ice-cream container to be produced in Turkey. Both Gabler and OMV are reportedly submitting proposals. The label would be four-sided instead of five-sided in order to reduce costs. Without the bottom side, the key challenge will be positioning the label, says OMV’s Johansson. A two-piece label is a possible solution.

Related Content

Manufacturer Helps Clean Up Global Waterways with Reclaimed Plastics

RSP and Oceanworks partnership diverts plastic wastes from waterways for incorporation into new products.

Read MoreUS Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreAutomation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreBrueckner Group USA Moving to Bigger Space

New facility in New Hampshire will serve the local customer base better and enhance capabilities in the North American market.

Read MoreRead Next

Thermoforming: Ready for In-Mold Labeling? - Illustrations Of IML System

The following photos illustrate the IML system for thermoforming developed by Marbach and Gabler.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More