Follow These Best Practices When Working With Heat Transfer Fluids

Effectively choosing, operating and maintaining thermal fluid can positively impact productivity in plastics processing.

Many applications in plastics processing require precise temperature control. Specialized heat transfer fluids are designed to reach and maintain these temperatures safely and effectively when used with plastics processing equipment, such as coating rolls and heaters.

Choosing a Heat Transfer Fluid

With so many thermal oils on the market, processors must take the time to understand their specific requirements. By matching the fluid to the system and the application, manufacturers can maximize efficiency and sustainability while reducing costs and environmental impact in the long term.

The chemical composition of the heat transfer fluid will often determine its properties. Mineral oils are often used for nontoxic, cost-effective applications with moderate temperature requirements, whereas synthetic fluids are designed to operate in higher temperatures for extended periods of time. In plastics processing, synthetic fluids are often a better choice than mineral oils because of the high temperature requirements. As a result, synthetic fluids will have a longer life span, extending time periods between fluid changes, when managed correctly.

After shortlisting fluids based on chemical composition, looking at operating temperature ranges will be key when selecting a heat transfer fluid for plastics processing. Molding processes, for example, require heat transfer fluid with a broad temperature range to ensure effective heat transfer and maximum efficiency across production. The fluid must be able to work efficiently at both the highest and lowest temperature required for the application, so manufacturers should look at the fluid’s minimum and maximum operating temperatures.

Once selected, engineers must drain, clean and flush the heat transfer system of older fluid before introducing the new heat transfer oil. This process will remove contaminants that were introduced when building a new system, or remove byproducts generated as the previous fluid degraded. Circulating a specialized cleaning and flushing fluid at temperature will activate the detergent additives that will mix with suspended loose particles.

Maintaining Thermal Fluid

Once introduced, thermal fluid will provide excellent service for many years … when properly maintained. If thermal fluid is left to operate for long periods of time without regular monitoring or maintenance, any potential issues may go unnoticed until they impact production.

Molding processes require heat transfer fluid with a broad temperature range to ensure effective heat transfer and maximum efficiency across production.

If the system temperature fluctuates too much, it will impact the product finish. For example, plastic materials that are exposed to very high temperatures for prolonged periods will lose strength and toughness, and if the temperature drops too low the material may not mold properly. By introducing proactive measures, such as regular thermal fluid sampling and analysis, engineers can reduce waste while slowing fluid degradation to improve overall efficiency.

Degradation will occur as a heat transfer fluid reaches the end of its life span but will accelerate if thermal fluids are heated above operating temperature or not regularly monitored and maintained. Operating at high temperatures for long periods leads to oxidation and thermal cracking. These processes produce contaminants, such as carbon, that may start to build up inside the pipes and negatively impact heat transfer efficiency, eventually causing blockages.

Regular maintenance is critical to ensure heat transfer fluids remain effective. Photo Credit: Global Heat Transfer

Regular thermal fluid sampling and analysis is essential to understanding oil condition. To ensure the sample is representative of fluid in operation, we recommend engineers take a closed sample when the system is live, hot and circulating. Thermal fluid specialists and independent analytical chemists can analyze these samples and provide advice on any interventions that will slow degradation.

These interventions could include changing the operating temperature, fluid dilution or commission of a Light Ends Removal Kit (LERK) that filters potentially harmful light ends from the system. Over time, engineers can also look at sample analysis to track fluid condition, looking for trends that will help them anticipate issues before they impact production or cause an unplanned breakdown.

System Maintenance

By introducing sampling as part of a preventive thermal fluid maintenance program, engineers can improve productivity, reduce costs and energy usage, and increase the life span of fluid which can contribute to reducing their carbon footprint. Manufacturers can also consult with experts to optimize heat transfer system efficiency and train staff at the facility to operate equipment in accordance with health and safety regulations.

To complement regular fluid sampling, proactively monitoring the system itself will help engineers maintain uptime. Daily checks of pipework, pumps and gauges give engineers an opportunity to identify any potential issues with core components. Detecting issues early on and keeping critical spares on-site enables engineers to clean, fix or replace any parts in a timely manner, reducing the risk of production losses and downtime.

During walkarounds, engineers can also check that the facility is clean and organized and that areas are correctly signposted. Improving general housekeeping and clearly posting procedures can both keep workers safe and aid productivity.

To complement regular fluid sampling, proactively monitoring the system itself will help engineers maintain uptime.

To continue delivering high quality products to the multiple industries that rely on these materials, plastics manufacturers must take proactive steps to maintain uptime. While it often operates in the background, heat transfer fluid is integral to many steps of the plastics processing process. Taking the time to select a fluid with the optimal temperature range and desired characteristics, introducing regular sampling to understand its condition and promoting best practice to safely and efficiently maintain the system are therefore key to increasing productivity in this growing industry.

About the Author: Clive Jones is managing director of Global Heat Transfer and is the founder and managing director of the Global Group of companies, which he set up when he was just 17 years old. The Global Group of Companies has a range of business interests from the supply of hygiene and industrial consumables, storage and distribution through to oil and thermal fluids. Jones is heavily involved in business development, nurturing overseas partnerships and distribution agreements in new territories along with strategic planning and developing new ways of solving problems for heat transfer in manufacturing industries. Contact: +44 (0) 1785 760555; globalhtf.com

Related Content

High-Temperature, Low-Flow Indicator for Mold-Cooling Applications

Burger & Brown Engineering has released a new high-temperature low-flow indicator to monitor flow inside critical, restricted cooling paths such as those with bubblers or baffles.

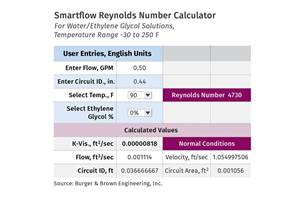

Read MoreCooling Geometry and the Reynolds Calculation

The original Turbulent Flow Rate Calculator worked well with a round circuit diameter, such as a drilled passage, but not as well using hydraulic diameters. Here’s how the problem was fixed.

Read MoreHow to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

Read MoreMachine-Side and Central Chiller Lines, Industry 4.0 Controls to Launch

Frigel will use K 2022 to showcase a number of developments in process cooling, including new and expanded lines of central and machine-side chillers, as well as advanced control platforms.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=970;quality=90)