Pushing the Limits in Overmolded RFID Tags

Processor Strategies

Startup molder devises new techniques for RFID tags.

Thanks to a new engineering resin and proprietary injection overmolding technique, Xtreme RFID in Grand Rapids, Mich., is producing one-piece, fully encapsulated RFID tags for asset tracking. Only two years old, Xtreme RFID was created as a new unit of Cascade Engineering, a multifaceted custom and proprietary molder, also based in Grand Rapids. Cascade had encapsulated RFID chips for municipal solid-waste bins since 2006 and formed the new unit to focus on this emerging business and technology.

Mike Lewis, business leader of Xtreme RFID, describes the new operation as “a small startup.” It has 10,000 ft2 of space, two injection machines of 100 and 250 tons, and four full-time employees. As for the market, Lewis says,“We’re still in the early adopter phase. But nearly every industry is developing the capability for RFID tags. Retail is the leader, along with medical and oil-and-gas industries.”

Xtreme RFID differs from most of its competition, which molds two-piece plastic casings and glues or sonic welds them together around the RFID tag. “That’s less rugged than what we do,” says Lewis. Insert molding the tag into a single piece of plastic provides the highest possible protection from water and chemicals. A coating over the electronic chip in the tag protects it from contact with the hot plastic. Still, preserving the electronics from damage by the heat and pressure of molding is the essence of the firm’s proprietary two-shot technique. Only a few other molders have tried this challenging route of one-piece overmolding (one other was discussed in a Close Up story last month).

The latest Xtreme RFID product is the Allied Series VX-Mid HT ultra-high-frequency (UHF) RFID tag for direct mounting on metal inventory. The Allied Series utilizes ViziCore RFID tags from Vizinex RFID of Allentown, Pa., as well as a new Fortron PPS compound from Celanese Corp., Florence, Ky. PPS offers high heat and chemical resistance (protection against fuels, oils, and solvents), as well as high mechanical strength for uses in harsh environments such as oil and gas industries, mining, commercial fishing, municipal solid-waste recovery, and general manufacturing.

The material is Celanese’s new Fortron ICE (Improved Crystallization Evolution) PPS, which is designed to crystallize at higher temperature than standard PPS, resulting in faster and more complete crystallization at lower temperatures and a finer, more uniform crystallite structure. Introduced at the last fall’s K 2013 show in Germany, Fortron ICE allows for as much as 33% faster cycles in complex parts, lower mold temperatures (allowing for hot-water instead of oil mold-temperature control), and improved demolding of complex parts with less breakage.

And these benefits are said to come with virtually no change in finished part properties compared with standard PPS grades. (Fortron ICE was the subject of a paper by Celanese’s Dr. Ke Feng at last month’s SPE ANTEC in Las Vegas.)

Xtreme RFID is using Fortron ICE 716A (65% glass and mineral filled). Lewis says it allows his molds to run at 100 C instead of the usual 200-210 C, cutting cycle time, which helps the RFID tags survive contact with 650 F melt temperature. “Before this, the high temperature was killing the chips,” Lewis notes.

Xtreme RFID has another version of the Allied Series tag in PP, but the firm can encapsulate tags in 10 different resins, including nylon, PE, TPV, TPU, and TPE.

Related Content

Larger Capacity Auxiliary Injection Unit Introduced

Mold-Masters has extended the capabilities of its E-Multi auxiliary injection platform, introducing the new larger capacity EM5 model.

Read MoreFakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

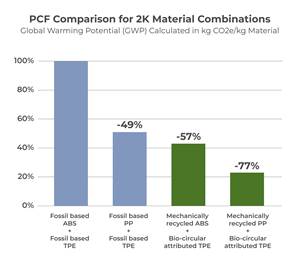

Read MoreMore Sustainable Two-Component Overmolding

Swedish compounders HEXPOL TPE AB and Polykemi AB have collaborated on a 2K sustainable development project for consumer products.

Read MoreNew Multicomponent Injection Molding Machine Line Launches

FCS Group’s X-Type parallel quartet injection molding machine features four injection units aligned in parallel for a smaller footprint.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More