Bollegraaf and Greyparrot Team Up in AI Vision Deal

Recycling facilities builder Bollegraaf invests in AI vision technology.

Bollegraaf, a builder of recycling facilities, announced a strategic partnership with Greyparrot, an artificial intelligence (AI) waste analytics company. As part of the agreement, Bollegraaf will transfer its AI vision business to Greyparrot and also make a cash investment in Greyparrot, for a total value of $12.8 million, while obtaining a noncontrolling stake in the company. It will also serve as a worldwide distributor and strategic partner for Greyparrot’s Analyzer, which currently provides visibility into waste streams at recycling plants across 14 countries using AI camera systems.

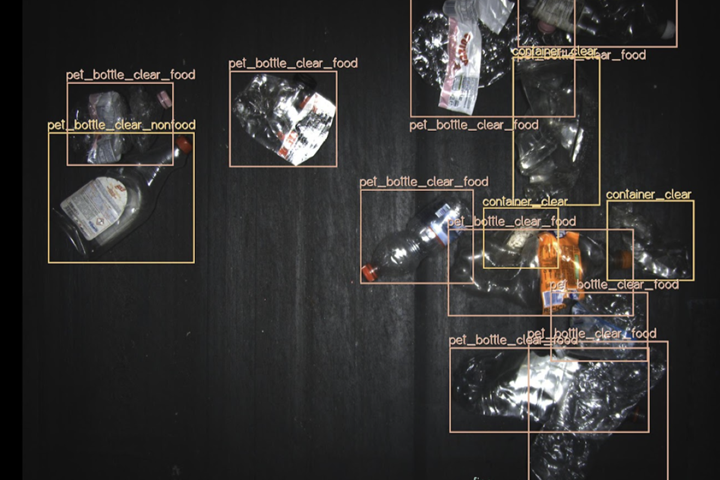

Greyparrott’s Analyzer uses AI to identify waste materials picked up by its vision system. Source: Greyparrot

As part of the deal, Greyparrot acquires Bollegraaf’s vision-based computing intellectual property and AI development team. Greyparrot will also open its first office in mainland Europe, to be located in the Netherlands.

The companies aim to retrofit thousands of existing materials recovery facilities (MRFs) and plastics recovery facilities (PRFs) with AI sorting capabilities, aiming to significantly boost recycling rates and quantify material emissions. Bollegraaf will provide the physical infrastructure, while Greyparrot adds the digital layer with its vision and analysis technology. According to Greyparrot, the Analyzer helped facilities analyze more than 25 billion waste objects in 2023, characterizing them into 70-plus categories in real time to reveal seven layers of data, including material type, financial value, brand and GHG emissions.

Greyparrot’s Analyzer system. Source: Greyparrot

Waste characterization practices at MRFs are often time and labor intensive, and can only be done at intervals. According to Greyparrot, the Analyzer system gives 100% visibility into waste composition, and does so in real time, providing managers with immediate and actionable information on the waste stream. Managers can then use this data transparency to demonstrate regulatory and contractual compliance with confidence.

“We have been looking to implement AI that can power fact-based and automated decision-making to provide our clients with a much more accurate overview of their waste composition and ultimately maximize their ROI,” says Edmund Tenfelde, CEO of Bollegraaf Recycling Solutions.

Related Content

-

Evolving Opportunities for Ambitious Plastics Recycler

St. Joseph Plastics grew from a simple grinding operation and now pursues growing markets in recycled PP, food-grade recycled materials, and customized post-industrial and post-consumer compounds.

-

SD Polymers: 'One-Stop Solution for Mechanical Recycling'

‘Passionate’ recycler invests in people and technology to meet commitment to innovative, sustainable solutions for its processor customers.

-

Recycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

.png;maxWidth=970;quality=90)