Crosslinking Process Promises Thinner, Higher-Performance PE Films

Technology combines UV curing system with photo initiator promoter masterbatch.

Kafrit, a well-known Israeli masterbatch and additives manufacturer, has collaborated with start-up Israeli additives company N3Cure to create what they call a breakthrough in crosslinking technology for PE films. The system combines a proprietary masterbatch called Crossitol with UV curing radiation to enable processors to produce PE films that will crosslink to improve sustainability and cut costs.

Under the arrangement between the two companies, N3Cure, specialists in polymers, UV curing and sustainability, provides the raw material for the crosslinking additive to Kafrit, which compounds it into a masterbatch. The UV technology is furnished by an undisclosed curing system provider.

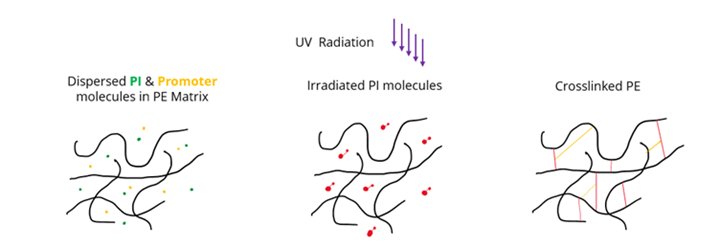

Crosslinking is the process of forming covalent bonds to join two polymer chains. With the Crossitol masterbatch, the process is triggered by UV radiation, applied by a UV curing system and integrated on an existing blown film line, resulting in a polymer web-like structure that is stronger than a regular, non-crosslinked polymer chain structure.

“UV crosslinking was designed to be a more cost-effective alternative to electronic-beam technology as it has a higher speed process, and lower maintenance and equipment costs. Unlike electronic-beam technology, selective crosslinking can be applied, and the finished product is easier to recycle,” said Kafrit’s Nadav Goldstein, v.p. of new business development.

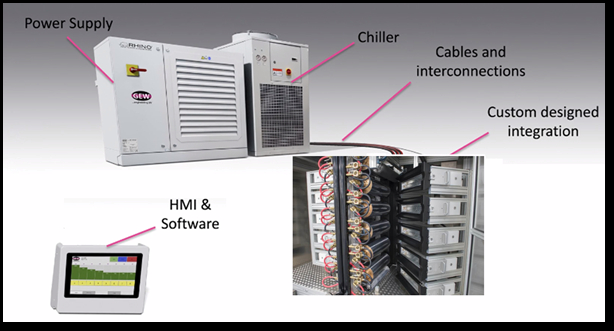

FIG 1 Components of UV curing system. Photos: N3Cure

FIG 2 Crosslinking PE generates a polymer web-like structure that is stronger than a non-crosslinked polymer chain structure.

The UV curing system is comprised of several units: lamps system (including rollers); chillers (air/water); power supply unit; and an HMI (Fig 1). It can be tailored for specific processing lines. This tailor-made process ensures quick and seamless installation, with minimal downtime to the production line. The masterbatch and UV curing system can be used in valid range of blown and cast-film applications.

To improve the crosslinking process even further, a promoter is dispersed in the PE matrix in addition to the photo initiator. A reaction between them occurs and improves the web formation as shown in Fig. 2.

As the companies explain, there are three main reasons to crosslink PE films:

- Sustainability: Crosslinking enables the production of recyclable packaging with a single-polymer structure, which facilitates post-consumer recyclability. A stronger web permits downgauging to reduce material usage. Because it’s crosslinked, the thinner film has the same mechanical properties as thicker film with a reduced carbon footprint.

- Economics: Compared to other radiation methods, UV crosslinking has a relatively low entry barrier. In double- or even triple-bubble film applications, it is said to increases bubble stability and production line output. It can also replace high-end polymers and increase savings on energy, labor, maintenance, and logistics costs.

- More Design Freedom: Crosslinking enables innovative product design with a focus on recyclability. Selective crosslinking (area specific) products allow flexible solutions to fit any customer needs and achieve superior packaging properties such as a wider sealing operating window; improved tensile and tear properties; stronger, faster, and higher percentage of shrinkage.

Kafrit and N3Cure says the UV curing systems and Crossitol masterbatch combination results in an entirely homogenous film and can target specific layers without affecting the other film layers. Non-crosslinked edges can be trimmed and recycled online or offline.

Additives supplier Polyfil, Rockaway, N.J. is a subsidiary of Karafit.

Related Content

Graphene Masterbatches for Flexible and Rigid Polyolefin Packaging and Beyond

Brazilian start-up Gerdau Graphene joins a growing group of graphene additives suppliers with a focus on boosting properties of large volume commodity thermoplastics.

Read MoreGraphene-Enhanced Stretch Film Billed as 'World First'

Thinner, stronger films to be commercialized by Brazil’s Packseven in August.

Read MorePFAS-Free Processing Aid for Blown Film Extrusion

Ampacet’s new processing aid said to perform as well as fluoro-based PPAs in blown film.

Read MoreBASF Highlighting How They 'Make, Use and Recycle Future Solutions'

NPE 2024: On May 8, company chairman and CEO Michael Heinz gives keynote session, “Our Plastics Journey: The Road to a Sustainable Future.”

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More