Additives at NPE: Many Routes To ‘Greener’ Plastics

NPE2012 News Wrap Up

Just as eco-friendliness was a major theme in materials news at the big show in April, so it was with additives.

Just as eco-friendliness was a major theme in materials news at the big show in April (see last month’s report), so it was with additives. Product debuts in Orlando included biobased plasticizers and lubricants for PVC, colorants and additives for PLA and other biopolymers, biodegradation promoters, amine-free antistats, non-halogen flame retardants, and compatibilizers that allow for higher incorporation of recycle content. Among other introductions were improved lubricants and processing aids for polyolefins, PVC, and engineering resins; new antimicrobials; light stabilizers for TPO sheet and film; liquid colorants and a black IR-reflective pigment; and foaming agents for fine cells and weight reduction.

SUSTAINABILITY EMPHASIS

PolyOne launched reFlex 100 fast-fusing plasticizer as a 94% biobased replacement for phthalates in PVC plastisols. Developed in collaboration with Archer Daniels Midland, it is derived from an oilseed byproduct and has USDA Biopreferred certification. It is said to act inherently as a heat stabilizer and to eliminate gelling during fusion. Unlike other alternatives, it can be blended into both existing phthalate-based and new non-phthalate systems, providing a formulating tool that helps reduce costs by improving productivity and eliminating defects while reducing the amount of plasticizer and heat stabilizer required. PolyOne will soon launch new blends of this bioplasticizer with DNTP to replace benzoate plasticizers.

Another new non-phthalate plasticizer for plastisols is K-Flex 975P from Emerald Performance Materials. This proprietary, fast-fusing, high-polarity dibenzoate ester is said to exhibit better resistance to extraction by solvents and oils, improved compatibility and stain resistance, and better fusion characteristics than conventional plasticizers. It also boasts lower fusion and gelation temperatures and higher fused strength.

Swiss-based Jungbunzlauer (U.S. office in Newton Centre, Mass.), introduced Citrifol BII line of tailor-made, fully-degradable citrate esters as an alternative to phthalates and other plasticizers, particularly for use in biopolymers such as PLA. Applications include mulch films or films used to prevent soil erosion. They can also be used in flexible PVC and plastisols. Benefits are said to include low migration.

DuPont Polymer Additives Group, formerly part of Danisco, highlighted Grindsted Soft-N-Safe, a four-year-old biobased plasticizer for PVC. It has found use in cling film, toys, medical devices, plastisols, and masterbatches. Made from castor oil and acetic acid, it is a 1:1 replacement for phthalates and other conventional plasticizers.

Clariant is offering a new generation of rigid PVC lubricants based on a renewable source. Licocare SBW11 TP is a chemically modified wax produced from soybean oil that acts as an external and internal lubricant and boasts superior performance over traditional fatty ester derivatives, particularly in Ca/Zn- or tin-stabilized film and extrusion applications. At low use levels of 0.3 to 1.0 phr, it reportedly provides good release, no mold deposit, and excellent heat and color stability.

Plastics Color Corp. recently signed an agreement with Bio-Tec Environmental LLC to use and distribute the latter’s EcoPure-brand bio-additive in North America. EcoPure is said to accelerate biodegradation of plastics in a biologically active landfill but will not affect processing or performance properties. PCC also offers biobased color and additive concentrates and formulations with various levels of post-consumer recycle and post-industrial regrind.

Americhem showcased its new nBalance color and additive masterbatches for plastics and fibers. These include products for PLA and other bioplastics, a “PCR-renewal” additive for PET, and formulations with natural fibers such as flax for unique aesthetic effects.

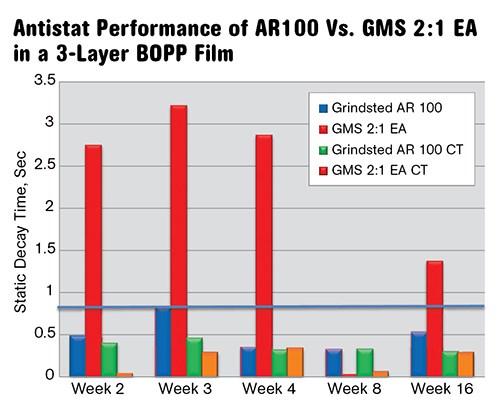

DuPont Polymer Additives Group also launched a new amine-free, biobased antistat for BOPP and PP films. Grindsted AR100 (another former Danisco product) has worldwide food-contact approval.

Struktol Company of America introduced RP 28 compatibilizer and blending aid that is said to ease incorporation of regrind and recycle into a wide range of plastics. Processors can expect to see improved physical properties and processability of such compounds, according to Struktol. In addition, RP 28 is useful as an alloying agent for engineered plastics because it provides improved dispersion and compatibility of the discrete-phase polymer, which often results in better physical properties.

Cray Valley launched the SMA 9000 series of styrene maleic anhydride masterbatches, which have been optimized to improve performance of nylons in extrusion and compounding. SMA 9001 was developed for virgin and clean recycled nylon to impart melt strength or compatibility in blends. SMA 9002 is said to compatibilize “dirty” recycle streams to allow using a higher proportion of recycled material without compromising properties. It restores melt strength of nylons contaminated with more than 10% PP, calcium carbonate, or other materials.

MORE LUBRICANTS & PROCESS AIDS

Struktol launched several new lubricants and processing aids under its Struktol brand:

RP 11 is a lubricant package said to provide an unmatched combination of viscosity reduction and mold release for PP resins and compounds. It can replace peroxide modifiers and internal or external mold releases. At loadings as low as 0.2%, it boasts increased melt flow and significant improvements in mold filling and release, potentially allowing greater use of regrind/recycled content.

RP 17 is a combination lubricant and odor neutralizer. First designed for reducing odors in wood-filled plastics, it has been modified for use in a variety of plastics that require a combination of lubrication, mold release, and odor masking. It can be used in recycled applications as well as interior automotive compounds where neutral odor may be a requirement.

TR 451 is another combination product designed to aid incorporation of fillers into polyolefins. It is said to provide significant viscosity reduction, mold release, and consistent processing. Test results show that addition to highly filled calcium carbonate/PP compounds allows for even higher filler loadings without adverse effect on processability or properties. Also, compounders using treated fillers may be able to substitute untreated fillers in combination with TR 451 to cut costs.

TR 044W provides a combination of viscosity reduction and mold release in PC resins and compounds at loading levels as low as 0.2%. Processors using the product in clear applications can expect minimal haze development even at high loading levels, according to Struktol. Improved processability can result in lower molded-in stress in injection molding.

TR 063A boasts a novel chemistry that makes it highly compatible with nylon 6 and 66. It is said to be superior in performance to other lubricants such as montan ester waxes. It can be added at the compounding stage or by the processor during product manufacturing.

Some suppliers struck the sustainability theme as a side benefit of using their products. For example,

Milliken said its Millad NX 8000 PP clarifier has improved solubility over other clarifiers, which has been shown to result in improved aesthetics at 10-15% lower melt temperatures, translating into lower energy consumption and 10% faster cycle times.

Phoenix Plastics showed off its Celspan 702 proprietary wax-based concentrate that boosts flow and raises the heat resistance of PVC, allowing processors to decrease the melt temperature and run faster. It also helps in processing regrind.

Heritage Plastics launched a new additive concentrate that reportedly provides improved part strength and faster cooling, leading to higher output and less warpage; as well as lower material costs, significant energy savings, and environmental benefits by displacing resin. It also allows injection molders to use calcium carbonate without increasing part weight. Heritage CF8000E is formulated with a chemical foaming agent and 76% calcium carbonate in LLDPE carrier. The calcium carbonate was selected to optimize the distribution of cell growth within the part. It is designed for use in a wide range of polyolefins at 10-20% loadings.

NEWS IN LIGHT STABILITY & COLOR

Two new light stabilizers were showcased by BASF. Tinuvin XT 847 is the latest addition to the company’s portfolio of NOR-HALS, which are said to impart superior light and thermal stability. The new grade is said to represent a significant advance in light stability for polyolefins. Field tests have shown it to significantly extend the durability of TPO roofing membranes.

Tinuvin 1600 is a new triazine UV absorber that is said to provide extremely long-lasting—up to 20-year—UV protection and heat stability. It is suited to monolithic and multi-wall PC sheets for ultra-high-durability architectural and automotive glazing, as well as BOPET films for photovoltaics, window films, displays, protective films, and PMMA laminations for very durable specialty applications like window profiles and photovoltaics. Other uses include SAN and ASA construction applications and automotive thin films requiring extended UV protection.

PCC launched the LiquiSol liquid color and additives system as a result of last year’s acquisition of Polysource. LiquiSol is a full system designed to make it easier for processors to integrate liquid colorants and additives into their operations, not as a replacement for solid color concentrates, but as alternatives for specific manufacturing processes. The LiquiSol package includes a complete analysis of a manufacturing center by PCC; the latest in liquid-color pumps, vessels, and storage systems; training for production staff; and customized colors and additive dispersions.

BASF highlighted its newest IR-reflective pigment, Sicopal Black K 0095. An inorganic, jet-black pigment, it does not absorb heat and is designed for auto-interior molded parts, coatings, and fibers. It is also finding uses in building/construction products and motorcycle helmets.

MORE NEW ADDITIVES

Reedy International introduced Safoam PN-40E, a foaming agent with a very narrow particle-size distribution for creating fine cells. Its proprietary carrier system allows its use in a variety of extrusion and molding applications ranging from food packaging to automotive and consumer electronics. It boasts compatibility in a wide range of plastics including PS, PE, and PP. When blended with specialty olefinic polymers and impact modifiers, PN-40E has been shown to improve physical properties like impact strength, elongation, and flexibility.

Phoenix Plastics highlighted Gaia AB 505, a new organic antimicrobial concentrate in LLDPE carrier that is said to retard growth of bacteria, fungus, and algae on plastics. The product has been tested in injection molding, film, and other extrusion applications. In independent testing, Gaia AB 505 has been shown to inhibit e-coli and staphylococcus. A loading of 4% to 6% will protect articles for one to two years. It should not be processed at temperatures above 428 F.

As reported in our March NPE preview, new antimicrobials were also featured by Americhem with its nShield masterbatches, Lonza with its newly acquired Vanquish zinc omadine antimicrobials from Arch Chemicals, and NanoBioMatters with its patented BactiBlock silver-functionalized nanoclays.

New additions to a line of non-halogen flame retardants from Clariant are Exolit EP 150 liquid and EP 200 solid reactive phosphorus-based products for epoxy thermosets. With unusually high phosphorus contents of 25% and 29% respectively, they are effective at low use levels for electronic, transportation, and construction applications. UL 94V-0 reportedly can be achieved at only half the loading levels of other FRs.

Related Content

At NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreCrosslinking Process Promises Thinner, Higher-Performance PE Films

Technology combines UV curing system with photo initiator promoter masterbatch.

Read MoreGraphene-Enhanced Stretch Film Billed as 'World First'

Thinner, stronger films to be commercialized by Brazil’s Packseven in August.

Read MoreRead Next

MATERIALS AT NPE: All Market Sectors Benefit from Large Crop of New Materials

Higher-performance and easier processing PE film resins for packaging, a one-pass crosslinked PE for photovoltaic (PV) wire and cable, several higher-performing nylons and TPEs, “greener” plastics, and enhanced styrenic and PC resins are among the new materials that made their debut at the big show in Orlando, Fla., last month.

Read MoreMaterials & Additives at NPE: Performance, Processability, And Sustainability

Bioplastics take center stage.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)