iNOEX LLC

1913 Olde Homestead Lane

Ste. 101

Lancaster, PA 17601 US

717-672-0870

inoex.com

About iNOEX LLC

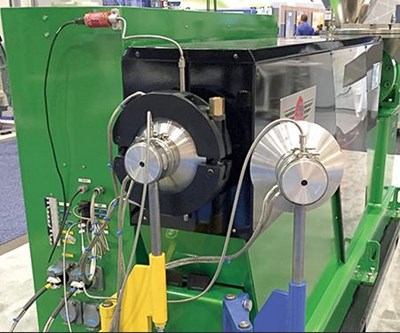

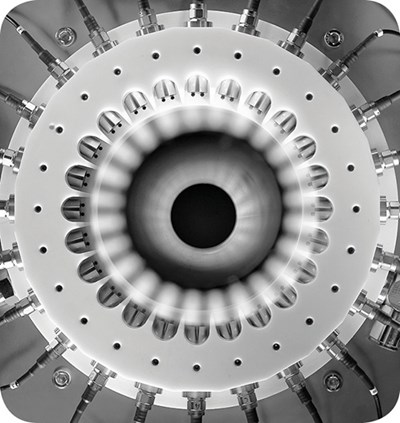

iNOEX helps clients make their products better, faster, and cheaper by leveraging advanced measurement and process control technologies for a variety of extrusion applications, including: blown film, pipe, profile, tubing, and wire & cable. We also offer data acquisition and visualization tools.

IS THIS YOUR COMPANY?

Video Gallery

iNOEX SAVEOMAT Liquid - How it works...

iNOEX SAVEOMAT DOS - How it works...

iNOEX AUREX ERS - How it works...

iNOEX – Success Story @ NAFFCO Flow Control, Dubai UAE

iNOEX GmbH and NAFFCO Flow Control: A Partnership Redefining Success NAFFCO was established in Dubai, UAE in 1991 to ...