Which Self-Contained Plastic Vacuum Loader is Best?

Sponsored ContentFor conveying resin materials over short distances there’s no more efficient and versatile way than using a self-contained vacuum loader. It may seem like a basic piece of equipment but selecting the right model can make a big difference in efficiency, process consistency, and reduced changeover time.

Share

If you’re still shoveling plastic pellets into hoppers, it’s definitely time to consider a self-contained vacuum loading system. It’s faster, easier and will automatically manage load and dump time. But as much as it might seem like all vacuum loaders are pretty much the same, there are features that will make a difference in any given application. Whether you are buying your first loader or your 10th, understanding these factors will ensure that you find the best fit for your situation.

Novatec provides a wide range of vacuum conveying systems and makes five different models of self-contained vacuum loaders. Here’s a quick overview of how to choose the best one for your application.

The Basics of Self-Contained Loaders

A self-contained loader picks up material from a nearby bulk container and automatically dispenses into an injection molding press or other process hopper.

Self-contained loaders accomplish the loading process automatically – eliminating the need for a person to climb a ladder with a bucket of resin to fill a hopper or bin. This saves labor, reduces material spillage and increases safety. There are loaders designed mainly for pellets and regrind while others are designed specifically for powders.

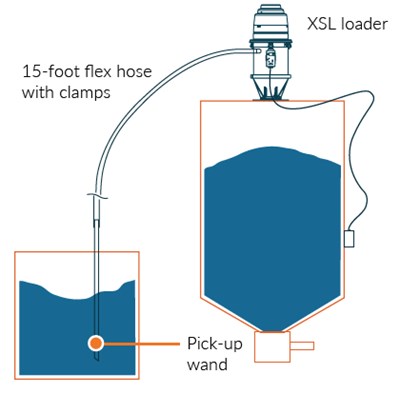

All self-contained vacuum loaders have an integral motor that creates a vacuum to convey plastic resin from a nearby bulk container, drying hopper or blender bin. The pickup of the plastic material is usually accomplished by an aluminum or stainless-steel tube, called a pickup wand, which is connected to a relatively short piece of flex hose attached to the vacuum loader. A small electro-mechanical control, usually at the end of a pendant, is set to manage load time, dump time and blowback (if that option is available) which is a feature that helps provide dust control.

All self-contained loaders provide this basic function, and the least expensive models do little more. But depending on your application, it may make sense to spend a little more to get features and functions that will improve your overall efficiency. Here are some important factors to consider.

Stainless Steel Construction – Steel construction is the entry point for self-contained loaders. However, anywhere corrosion could be an issue stainless steel construction is recommended. For FDA-approved processes it will be required.

Double-pivot positioning, available on Novatec XSL and GSL vacuum loaders provide easy access for cleaning.

Cleanability – The more materials you run and the more frequently you change over, the more important the ease and thoroughness of cleaning becomes. Novatec addresses this issue on its GSL and XSL models with a more accessible design. To clean, the loader can be tipped forward and the lid tipped back and locked in an open position. The accumulator can now be easily accessed for cleanout and the filter removed and replaced after blowout.

Dependable Operation – To operate reliably over time attention must be paid to ensuring loads are delivered cleanly, consistently, and reliably. Novatec employs several key design features to make this happen. The SureSeal flapper valve, which opens to deliver each load, is self-aligning and uses no gasket to achieve a tight seal after each discharge. MicroBurst is a high-intensity blowback air blast that cleans the whole filter area to remove dust and fines after each load is dispensed. It also cleans the flapper valve to ensure no residual material can compromise the integrity of the seal for the next cycle.

Novatec’s full-featured controls enable easy parameter changes, no-load alarms as well as proportioning and purging control.

Control – A self-contained vacuum loader will typically come with a side-mounted or pendant control. The pendant is more convenient as it allows the operator freedom of movement around the press and loading station. A simple control will provide programmable load and dump times. A full-featured control can provide functions such as the ability to make on-the-fly loader parameter changes, no-load alarms as well as proportioning and purging.

Motor – A fundamental choice is whether to get a brushed or brushless motor. The obvious issue is maintenance in that motor brushes are wear parts and must be replaced after approximately 300 running hours. Brushless motors can often run for years without maintenance. Less understood is that brushless motors are typically more powerful and efficient. With the ability to move more material in less time, you can decrease overall motor running time, further reducing maintenance as well as power consumption.

For a great many applications, a brushed motor will serve just fine and factors such as cleanability and dependable performance will be more important. But for higher volume situations, it may be well worth the premium to get a brushless motor.

Three Self-Contained Loaders from Novatec

As mentioned earlier, Novatec offers a variety of self-contained vacuum loaders in order to provide the best combination of price and features for any given application. Here are three models that are recommended for conveying pellets and regrind.

The MicroBurst blowback function removes dust and fines from the loader and cleans the SureSeal flapper to ensure tight seals for each load cycle.

VL Series Loader - Standard VL series models are designed for flange mount to existing bins or hoppers. Machine-mount packages provide a quick disconnect glass tube base with an integrated vacuum flapper. With a stainless-steel body and remote mount mini-PLC control, the loaders are modular in that you can set the inlet to any orientation required to fit the application. It has an external blowback accumulator tank which enables automatic filter cleaning to minimize dust buildup. It has 1.5 to 38 lb. of load capacity and can accommodate 1-½ or 2” inlet lines.

XSL Series Loader – Novatec’s newest addition to its self-contained loader line brings a full suite of user-friendly features to a brushed motor model. Double-pivot access enables quick and easy cleanout. The high-intensity MicroBurst blowback function includes an internal accumulator to clean the whole filter area of dust and fines. It also cleans the SureSeal flapper after each cycle enabling a consistently tight seal without the need for gaskets. The full-featured, plug-In pendant control supports loader parameter changes, alarms and acknowledgements. It has 12 or 19 lb. capacity and accepts 1-½” inlet lines.

GSL Series Brushless Vacuum Loader - The GSL Series Loader has all the features of the XSL Series plus a brushless motor which Novatec says lasts 4 to 5 times as long as motors with brushes. It is available in 12 and 19 lb. capacity and accepts 1-½” inlet lines.

Which loader is right for you? Go here for more information on Novatec Self-Contained Loaders, or Contact Novatec for expert advice on any application.