Plastics Use in the Packaging Industry

Plastics are used to manufacture flexible packaging and rigid packaging in applications like caps, closures, bottles, film, and sheet.

ESSENTIAL READING

VIEW ALLHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

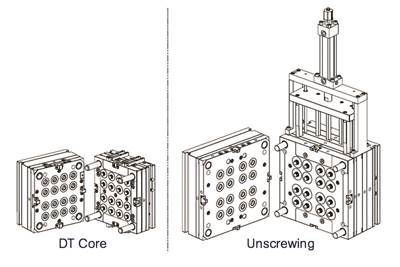

Read MoreBest Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

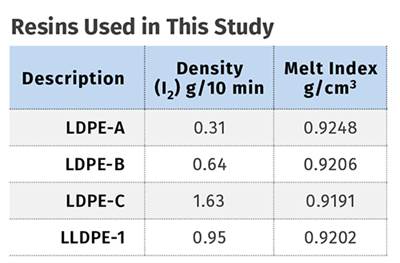

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreProtolabs Addresses How to Survive a Pandemic with Digital Manufacturing

Protolabs survey results examine product development and the supply chain.

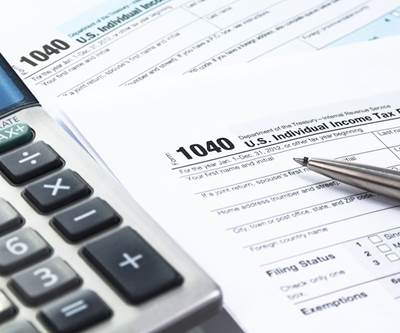

Read MoreWhat Plastics Processors Need to Know about Tax Reform and Equipment Acquisition

The Tax Cuts and Jobs Act of 2018 (TCJA) is positioning plastics processors for more growth and profitability following the most recent Plastics Processing Index showing the best quarter since 2013 when the index began.

Read MoreLatest Packaging News And Updates

Higher Productivity & Energy Savings for Packaging, Industrial Parts

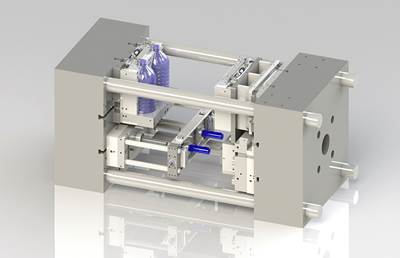

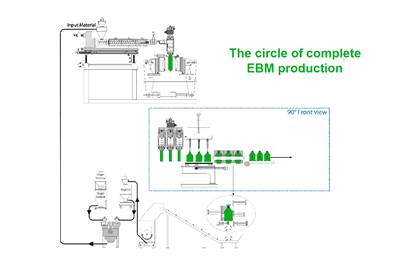

NPE2024: Bekum is running EPET on its first U.S.-built all-electric shuttle. it is also highlighting the new XBLOW 200 industrial machine with new clamp design, plus a new extrusion head, three-layer retrofits, energy-saving extruder and EBLOW 08 electric shuttles.

Read MoreAdvanced Inspection of Bottles and Labels

NPE2024: Intravis shows new system for full label inspection on round, randomly oriented bottles; and redesigned bottle inspection system with more modular design.

Read MoreSI Group Gets FDA Approval Extension for Weston 705 & 705T

SI’s phosphite antioxidants get ‘green light’ for use in PET food-contact packaging

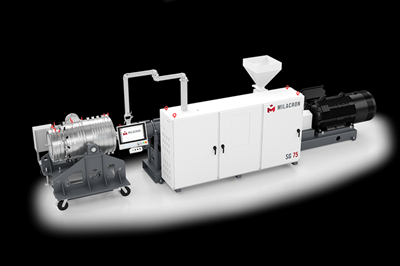

Read MorePipe Extruder, Die Heads Plus a Cobot Demo

Milacron to debut updated extruder, control and die head packages. Also demonstrating how cobots can be used to automate pipe production.

Read MoreAll-Electric IMM Advances for Packaging, Medical and LSR

NPE2024: Sumitomo SHI Demag’s show focus will be on application of all-electric injection molding machine technology for a variety of markets and components.

Read MoreSpecialized Machine, Tool Achieve Record Levels of Cap Molding

NPE2024: Netstal says its CAP-Line injection molding machine running a 128-cavity z-moulds tool will produce 26-mm tamper-evident caps for still water in just a 1.9-second cycle.

Read MoreFeatured Posts

In the Zone: Packaging

The Packaging Zone is the place to learn about the latest in customer product delivery.

Read MoreAustrian Recycler's Mission to Recycle PET Takes It Beyond Bottles

Mission PET supplements bottle-to-bottle capability with alternative applications for recycled PET.

Read MoreAt NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read MoreGet Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

Read MoreBreaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

Read MoreUS Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreFAQ: Packaging

The following are four other common issues, applicable to both single- and two-stage processes.

-

Pearlescence and haze

-

Insufficient top-load strength

-

Insufficient base clearance or rocker bottom

-

Drop-impact failure

.png;maxWidth=300;quality=90)