Plastics Industry Automation

Automation in the Plastics Industry involves robots, cobots, molding cells, part pickers, and end-of-arm-tooling.

ESSENTIAL READING

VIEW ALLWhat to Look for in High-Speed Automation for Pipette Production

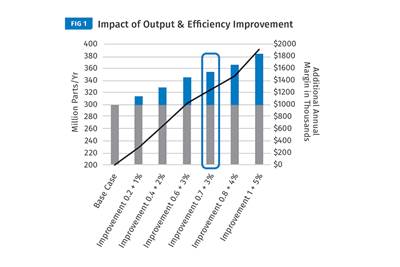

Automation is a must have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floorspace consumption and payback period.

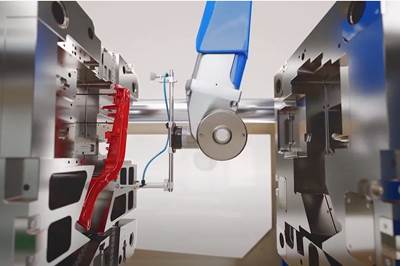

Read MoreHow to Automate High-Precision ‘Micro’ Insert Molding

What does it take to automate a horizontal injection molding cell to handle micro-sized inserts and molded parts? General-purpose top-entry robots and tooling may not be up to the job.

Read MoreHow to Plan and Implement Automation in an Injection Molding Plant

There is no “one size fits all” solution in automation. When considering what it would look like in your plant, hone in on the staff, products, space, and goals that are specific to you and the automation system that you will be installing.

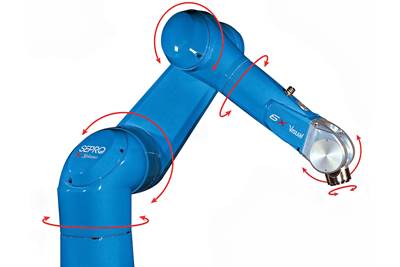

Read MoreAUTOMATION—PART 2 When to Consider Six-Axis Articulated-Arm Robots

Extraordinary versatility suits articulated-arm robots to a wide variety of operations, from loading inserts and unloading parts to decorating, assembly and testing. They also pair well with Cartesian robots. Many mounting options and improved speed and ease of programming add to their flexibility.

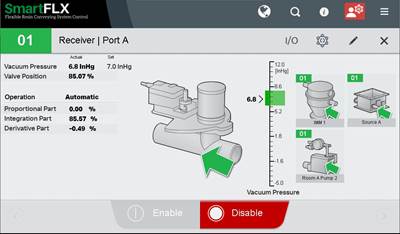

Read MoreHow to Make Your Pneumatics ‘Smart’

Emerson’s Avantics Smart Pneumatics Analyzer digitizes the analog pneumatic environment and monitors and analyzes key operating data.

Read MoreImplementing Automation Systems: How to Do It Right

If you’re thinking of putting a complex automation system for high-volume consumables into your plant, consider these tips on making sure both you and your supplier are ready to give it the best chance of success.

Read MoreLatest Automation News And Updates

AI Manages Resin Drying Airflows and Throughputs for Energy Savings

NPE2024: Optional feature automates the process of maintaining process-ready resins at perfect temperatures and varied throughputs, while preventing overdrying and realizing significant energy savings.

Read MoreCoiling System Features Automated Spool Removal

NPE2024: Designed for wire and cable and tubing, system is equipped with a Yaskawa cobot for automated spool removal.

Read MoreAdvanced Inspection of Bottles and Labels

NPE2024: Intravis shows new system for full label inspection on round, randomly oriented bottles; and redesigned bottle inspection system with more modular design.

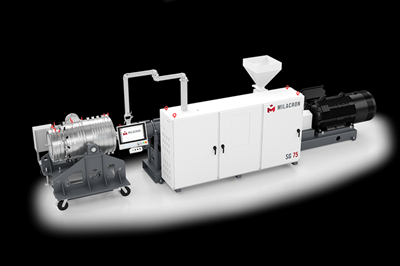

Read MorePipe Extruder, Die Heads Plus a Cobot Demo

Milacron to debut updated extruder, control and die head packages. Also demonstrating how cobots can be used to automate pipe production.

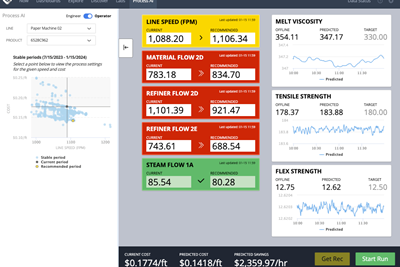

Read MoreConveying System is AI-Driven

NPE2024: New system creates and maintains optimal source-to-destination material flows.

Read MoreFaster Top-Entry Model Among 19 Robots in Orlando

NPE2024: Sepro Group will introduce the newest S5-25 Speed robot, promising 63% faster acceleration, as one of 19 robots on display at its booth and partner booths at the show.

Read MoreFeatured Posts

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

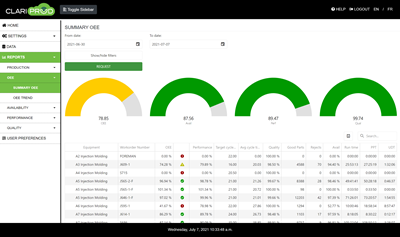

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreUse AI, Machine Learning to Take Variability Out of Manufacturing

Variability has always created insurmountable challenges for manufacturers. However, in the last decade, impact has been more painful due to a lack of experienced workforce. By leveraging technological advancements, particularly in AI, manufacturers can gain a transformative competitive advantage in both cost reduction and workforce development.

Read MoreCobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.

WatchChoosing the Right Projects to Automate

What are the strategies and upfront work that go into identifying production problems that could benefit from an automation solution?

Read MoreEnsuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

Read MoreFAQ: Automation

How to add automation to injection molding?

There is no “one size fits all” solution in automation. When considering what it would look like in your plant, hone in on the staff, products, space, and goals that are specific to you and the automation system that you will be installing.

Automation Supplier Categories

- Rebuilt Screws or Barrels

- Other Testing/Analysis Equipment

- Automation/Systems Integration

- Speed, Drive Controls

- Recording Instruments

- Troubleshooting, Problem Solving Systems

- Technical and Trade Associations

- Machining, Routing Software

- Materials Formulating Systems

- SPC, SQC Systems

- Product & Tool Design, Analysis Software (CAD/CAM/CAE)

- Assembly Robots and EOAT

- Flow Monitoring/Control Devices (for Liquids)

- Training Programs in Plastics

- Maintenance Management Systems

- Timers

- Rebuilt Motors and Drives

- ISO 9000 Software

- Job Quoting, Cost Estimating and Accounting Systems

- Dewpoint Monitors/Moisture Analyzers

- Parison Programmers

- Spray Painting Robots and EOAT

- Scheduling, MRP, Production and Inventory Management Systems

- Pressure Controllers, Monitors

- Temperature Controllers, Monitors

- Computer and Automation Testing Auxiliaries

- Color Matching/Formulating Systems

- Temperature Pyrometers, Sensors, Thermocouples

- Design of Experiments (DOE) Software

- Motion or Position Controls

- Part or Sprue Removal Robots and EOAT

- Screw Design/Analysis Software

- Sequence Logic Controls

- Level Sensors and Controls

- Used Molds

- Closed-loop Process Control Systems

- Used Machinery

- Machine Monitoring/Alarm Systems

- Pressure Sensors, Transducers

- General Purpose Robots and EOAT