Thermoforming

In thermoforming, plastic sheet is heated to a pliable temperature then shaped into a part by a male and female mold with the help of a vacuum. Categorized as thin-gauge or thick-gauge, the process is used to create products like clamshells, trays, and cups.

ESSENTIAL READING

VIEW ALL‘Back to Basics’ Fuels More Innovation at Thin-Gauge Former

Shift from private to capital ownership give Tray-Pak a boost.

Read MoreThermoforming PLA: How to Do It Right

Polylactic acid (PLA) resins are made from 100% renewable resources such as corn, sugar beets, or sugarcane.

Read MoreHow to Thermoform Top-Quality IMD Inserts

Wider adoption of in-mold decorating (IMD) for demanding industries like automotive, appliances, and consumer electronics will require thermoformers to have the right know-how and equipment.

Read MoreLatest Thermoforming News And Updates

Winners Announced for SPE Thermoforming 2023 Parts Competition

More than 30 entries were considered, including 10 in the Sustainability category.

Read MoreHagan Named SPE Thermoformer of the Year

Fifty year veteran of thermoforming industry to receive award during October’s conference.

Read MoreSPE Thermoforming Division Announces Biennial Parts Competition Call for Entries

This year’s parts competition includes two new categories with a focus in innovations in the use of sustainable thermoforming and in applications for electric vehicles and batteries.

Read MoreOMV Technologies Gets New CEO

Kooper brings 33 years of experience in the industrial and consumer packaging industries to OMV--the closed-loop, turnkey, inline extrusion, thermoforming and tooling systems manufacturer.

Read MoreEnhanced Digitization in Thermoforming

Illig’s Easy product family includes the newly developed Human Machine Interface, Illig Easy Touch.

Read MoreNew Illig Tool Network for North America

Mexico’s GIC becomes Illig’s first certified thermoform tooling partner.

Read MoreFeatured Posts

Clock's Ticking: Register Now for 2023 SPE Thermoforming Conference

Three-day event kicks off Oct. 24 in Cleveland.

Read MoreThermoformer Maximizes Productivity with 3D Printing

Productive Plastics has created an extensive collection of 3D printed manufacturing aids that sharply reduce lead times.

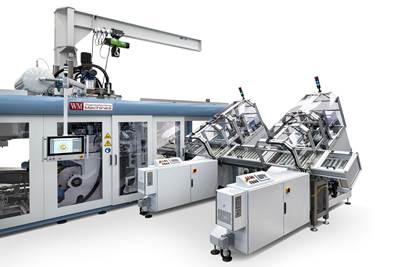

Read MoreAutomation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreNovel ‘Clamtainer’ Extends Thermoformer's Reach in Packaging

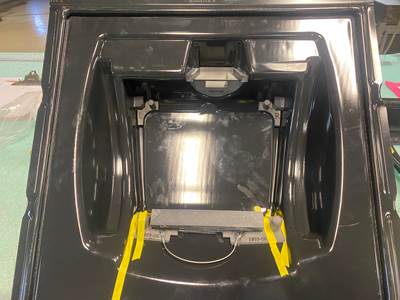

Uniquely secure latching expands applications for Jamestown Plastics’ patented clamshell package design.

Read MoreThermoforming PCR: An Equipment Supplier’s Pointers

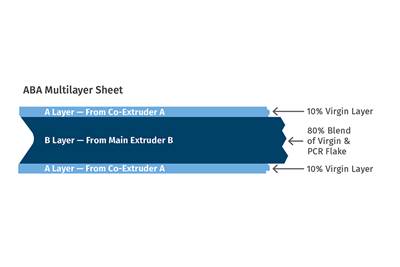

Thermoforming PCR is not radically different from forming virgin, but variation in recycled materials can require extra care to get a consistent end result. Start by examining every aspect of the process from the sheet (and extrusion process if run inline) to the final trim.

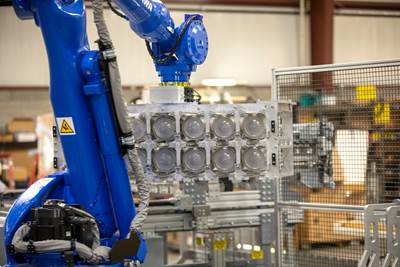

Read MoreAn Automation 'First' for Non-Servo-Eject Trim Presses

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.

WatchFAQ: Thermoforming

How to fix a thermoformer?

Some shot-to-shot misalignment may occur even if the above adjustments to the rail are made. When issues arise, especially today, when OEMs’ technicians can’t travel to service and maintain equipment in person, it can be helpful to have a checklist for troubleshooting.

Here are 10 of the most important steps for troubleshooting misalignment and other common issues in thermoforming.

Thermoforming Supplier Categories

- Thermoformers

- Thermoforming Molds

- Nonferrous Metals for Molds

- Mold/Die Management Systems

- Mold Steels

- Cutting, Stamping, Trimming Dies

- Mold Making and Repair Equipment

- Mold Components

- Mold Grease

- Compression/Transfer Molds

- Mold-cleaning and Maintenance Chemicals

- Nonmetallic Tooling Materials

- Compression/Transfer Presses

.png;maxWidth=300;quality=90)