Resin Conveying

Resin conveying includes central conveying; material handling; vacuum conveying; pneumatic conveying; transferring resin; angel hairs.

ESSENTIAL READING

VIEW ALLFollow These Steps to More Efficient Central Pneumatic Conveying

Depending on when you bought and installed it, there are ways to tweak your central pneumatic conveying system to improve its performance and save you some money.

Read MoreHow to Maximize Your Conveying System Performance

If your conveying system isn’t up to snuff, and you don’t have the budget to overhaul or expand it, don’t lose hope. There are many factors that could be limiting your conveying performance, and a number of them cost little or nothing to fix.

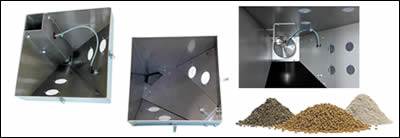

Read More10 Things to Know When Specifying Vacuum Conveying Systems for Powders

The priority is to maximize movement of powders while minimizing dust exposure.

Read MoreHow to Choose & Use Metal Separators

Use of magnets for removing ferrous contaminants in an industrial environment began in the 1940s to help farmers trap and remove metal contaminants from their grain chutes.

Read MoreHow to Set Up & Maintain An Efficient Resin Handling System

In today's world, having a reliable resin-handling and conveying system is as important as having reliable electrical power.

Read MoreHow to Minimize Problems With Gravimetric Blenders

The first and best way to avoid blending problems is to choose the right gravimetric blender for the application.

Read MoreLatest Resin Conveying News And Updates

Loaders, Blenders Made Specifically for Medical Processors

NPE2024: FDA-compliant auxiliaries suited for injection, extrusion, blow molding.

Read MoreCompact, Mobile Dryer Has Unique Conveying Capabilities

Mobile dryer includes closed-loop conveying to minimize the use of ambient air for resin movement.

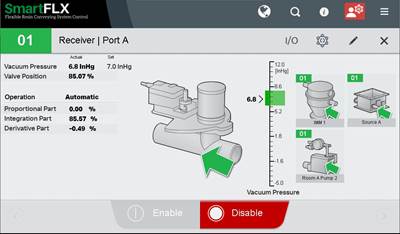

Read MoreConveying System is AI-Driven

NPE2024: New system creates and maintains optimal source-to-destination material flows.

Read MoreSoftware Helps Processors Make Better Business Decisions

NPE2024: Tracker Monitoring and Reporting Software supports ISO reporting and material validation, including PCR usage and equipment status monitoring.

Read MorePiovanGroup Rebrands, with Mostly Minor Name Changes

For the most part, subsidiary company names will remain, with slight modifications meant to enhance the Group’s identity.

Read MoreRadar Level Sensor Streamlines Bulk Material Inventory Management

NPE2024: The NCR-86 is designed to ensure rapid data updates, enhancing efficiency in inventory management.

Read MoreFeatured Posts

‘Digitalization’ – Awkward Term for a Vital Concept

At K 2022, 85 machines from 40 companies showed off their Industry 4.0 capabilities via OPC-UA interface. A new universal interface for Material Supply Systems was revealed at the show.

Read MoreWisconsin Firms Unite in Battle Against Covid

Teel Plastics opened new plant in record time, partnering with AEC & Aqua Poly Equipment Co. to expand production of swab sticks to fight pandemic.

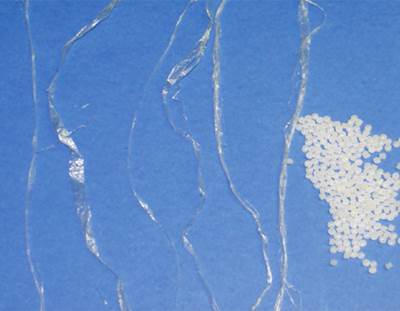

Read MoreSix Tips to Prevent Those Annoying Streamers

Streamers are a vexing problem that can foul up production. If you have time and budget constraints, there “at-home” solutions you can try. But once you’ve exhausted those routes, you might have to throw a little money at the problem. Here’s a process engineer’s view of things.

Read MoreLooking to Handle More rPET? Don't Overlook Your Conveying System

There is a lot of important process equipment in PET recycling plants, and pneumatic and mechanical transfer systems connect them all. Downtime due to poor transfer system design, incorrectly applied components, or the lack of maintenance should not be a fact of life. Demand more.

Read MoreMedical Molder Boasts Showpiece Material-Handling System

Flex Manchester is so proud of its new, elaborate drying/conveying system that it greets visitors front and center on their way to view the cleanroom molding floor.

Read MorePaving the Road to a Circular Economy

Sustainability and circular economy aren’t buzz words. They are and will continue to be the way of doing business for processors.

Read MoreFAQ: Resin Conveying

How to prevent streamers?

-

Adjust solids-to-air ratio with bleed off value

-

Cool the pellets more

-

Streamer screener

-

Air-to-air heat exchangers

-

Specialty elbows and shot pinging

-

Change the transfer system

Resin Conveying Supplier Categories

- Cellulose Acetate Propionate

- Starch-based Polymers

- Nylon--Type 6

- Polycarbonate/ABS Alloys

- PVC--Dispersion and Blending Resins

- PPE/Nylon Alloys

- Cellulose Acetate Butyrate

- Polyester (Thermoplastic)--PETG Type

- Conveyors (parts-handling)

- Polyethersulfone

- Adhesion-Modified HDPE

- Polyphthalamide (PPA)

- PVDC--Coating Grades

- Polyphosphonate

- Other Styrene Copolymers

- Acrylic/PVC Alloy

- Polycarbonate/Polyester Alloy

- PVC--Flexible Compounds

- Polyester (Thermoplastic)--PCT Type

- Desiccant for Dryers

- Thermoplastic Elastomers--Polyamide Type

- Polyamide, Aromatic

- Nylon--Type 69

- Ionomers

- Liquid Crystal Polymers

- Ethylene Plastomers

- Nylon/Polypropylene Alloys

- Nylon--Type Mxd6

- Ethylene Vinyl Alcohol (EVOH)

- Polyester (Thermoplastic)--PBT Type

- Conveying Equipment (pneumatic and Mechanical)

- Polyarylether

- Styrene Maleic Anhydride (SMA)

- Prepregs (thermoplastic)

- Metal Detectors, Separators

- Stacking, Packing Equipment

- LLDPE

- ASA Copolymers and Alloys

- Nylon/Abs Alloys

- Polyarylate

- Silos

- Polybenzimidazole (PBI)

- Polysulfone

- Cyclo-olefin Polymers

- PVC--Rigid Compounds

- Valves, Gates, Diverters

- Thermoplastic Elastomers--Olefinic Type

- Polyester (Thermoplastic)--PTT Type

- Nylon--Type 610

- PVC--Chlorinated PVC (CPVC)

- Thermoplastic Elastomers--Urethane Type

- PHA, PHBV Biopolymers

- Polyphenylene Sulfide (PPS)

- Nylon--Type 612

- Adhesion-Modified LDPE

- PPE/PP Alloys

- Polyester (Thermoplastic)--Other Types

- Ethylene Vinyl Acetate (EVA)

- Acrylics

- Hoppers, Bins, Tanks

- Polystyrene

- SAN

- Cellulose, Ethyl

- Box Tilters

- Polymethylpentene

- UHMW PE

- Polycarbonate

- Polyester (Thermoplastic)--PCTG Type

- Polyestercarbonate

- Nylon--Type 6/66 Copolymer

- Acrylic Copolymers

- Resin Clean-up Solutions

- Polyetherimide

- Syndiotactic Polystyrene (SPS)

- Polyarylsulfone

- PVC--Plastisols, Organosols

- Nylon--Type 11

- Polybutylene

- Polyetheretheketone (PEEK), Polyetherketone (PEK) and Other Polyketones

- PPE/PS Alloys

- Unscramblers, Orienting Devices

- LDPE

- PVC--Suspension or Mass General-purpose Resins

- Hopper Loaders

- Nylon--Amorphous

- Nylon--Type 46

- Thermoplastic Elastomers--Vinyl Type

- Polyphenylsulfone

- Lifting Devices

- Metering, Proportioning Equipment

- Acetal

- AES Terpolymer

- PVC--Copolymer Resins

- Parts/Runner Separators

- Dryers for Resins

- Acrylonitrile Copolymers

- Polyester (Thermoplastic)--PET Type

- Adhesion-Modified LLDPE

- Bag and Drum Dumpers

- Polyamide-imide

- Ethylene Copolymers and Alloys - Other

- ULDPE/VLDPE

- HDPE

- EPS Bead (including Copolymers)

- Expandable Polyolefin Bead

- Acrylic/Polycarbonate Alloy

- Semi-bulk Containers

- Polyimide (Thermoplastic)

- Feeders

- Polyester (Thermoplastic)--PCTA Type

- Fluoropolymers

- PVDC--Extrusion & Molding Grades

- ABS/pvc Alloy

- Thermoplastic Elastomers--Styrenic Type

- Nylon--Type 12

- Thermoplastic Urethane (Non-Elastomeric)

- Nylon--Type 66

- Thermoplastic Elastomers--Polyester Type

- Polypropylene (including Copolymers)

- Polylactide (PLA) Polymers

- ABS

- MDPE

- Weigh Scales

- Phenoxy

- Cellulose Acetate

- Butadiene Styrene Copolymers (not Including Elastomers)

- Nylons - Other

- Thermoplastic Elastomers--Polyether Block Amide (PEBA) Type