Composites: Lightweight Materials Take on Bullets and Bombs

Topping the news from the year’s biggest composites show are PP ballistic panels, “stealth” composites, thermoplastic RTM, new tooling concepts, microwave curing, “instant” SMC, and laser projection for QC and ply layup.

History shows that wars drive plastics development, and the Iraq war is no exception. It’s bringing among other things an urgent need to retrofit vehicles and buildings against bullets and homemade bombs. The JEC composites show this spring in Paris revealed active R&D in lightweight ballistic composites—especially ones made of high-strength PP tape. (They also have civilian uses in resisting gravel impact on bus underbodies.) New radar-absorbing “stealth” composites were also on display.

Other developments include adaptation of thermoset processes such as RTM for thermoplastic composites, faster processing of both thermoplastics and thermosets with novel tooling or microwave curing, “instant” SMC that goes directly from mixing into the mold, and laser projection for part inspection and ply layup. (Next month, we’ll cover more JEC composites news, including developments in materials, fibers, cores, and software.)

PP tapes go ballistic

High-strength fibers used to stop bullets and absorb their impact are traditionally aramid (DuPont’s Kevlar or Teijin’s Twaron), carbon, and S2 glass. Some of these materials are in short supply. Some are dense and add weight. Hence the mounting interest in ballistic composites made of high performance oriented PP tape, which is readily available and lightweight.

Propex Fabrics Inc. (formerly BP Amoco Fabrics) is testing its Curv homopolymer PP tape in woven fabric, which is compacted by a patented process into sheet that can then be thermoformed. Ballistic tests performed in Europe last May showed that a 17.8-mm Curv sheet weighing 16.2 kg/m2 meets the requirements of the National Institute of Justice (NIJ) level IIIA protection, stopping .44 magnum bullets at speeds of up to 470 m/sec and standard 9-mm police bullets at up to 522 m/sec.

Propex is also performing ballistic tests on other structures—for example, a laminate of five 3-mm Curv panels joined with EMA adhesive; a laminate of four 4-mm Curv panels; and combinations of Curv fabric with Twaron CT 707 high-tenacity fabric made of patented micro-filament yarn.

Curv sheet is also being commercialized where it takes hits from pebbles, not bullets—in 12 x 4 ft underbody panels for a European bus. Parts so large couldn’t be compression molded in one piece with long-glass-filled plastic because the clamp pressure would have been too great. Curv fabric can be compression molded into sheet at only 200 psi.

Exploring a related technology, Lankhorst Indutech in the Netherlands is testing ballistic panels made of its “PURE” oriented-PP tape, which is made with a PP homopolymer core and lower-melting PP copolymer coating. It can be consolidated and thermoformed in one step. In recent tests, a 22-mm-thick PURE panel weighing 18 kg/m2 reportedly stopped .44 magnum bullets. Also being tested are ballistic panels that combine PURE tape with ceramic sheet for protection against Level IV (armor-piercing) bullets. Lankhorst is working on portable enclosures for bomb-disposal squads to isolate suspected explosive devices.

Milliken & Co. has licensed Lankhorst’s PURE technology to make MFT (moldable fabric technology) oriented-PP tape. Milliken’s MFT panels at a weight of 13.7 kg/m2 also can withstand .44 magnum rounds and is being used commercially to armor military vehicles. Milliken is testing panels consolidated from multilayer stacks of MFT tape with glass, aramid, and high-strength PE fibers, as well as ceramic sheet. It is also experimenting with its nucleating additives to improve PP properties.

Stealthy composites

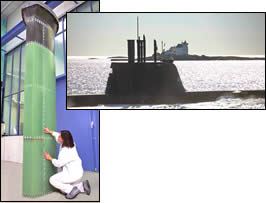

Stealth or “low observables” is another active area of composites development. The latest in stealth veils was shown by EADS (European Aeronautic Defense and Space Co.). It combined a commercially available veil of glass and carbon fibers with a micro-porous, semi-permeable PTFE membrane. It is said to have superior stealth properties, regardless of part shape. It was shown on an oval submarine tower, which EADS has molded commercially since 2003 using its patented VAP (vacuum-assisted process). The PTFE veil withstands the 350 F molding process and also lets bubbles out of the composite.

Thermoplastic RTM

JEC saw an unusual adaptation of the thermoset RTM process to thermoplastic, with potential to achieve faster molding cycles and better surface quality. The Fraunhofer Institute in Germany is developing a thermoplastic RTM-like process called Cast-Polyamide. It combines caprolactam with catalyst and inhibitors in a mixing head to polymerize nylon 6 within a mold containing continuous-fiber reinforcements. The nylon takes roughly 3 min to polymerize—longer than melt-forming processes such as compression molding, but polymerization takes place at a lower temperature (300 F), so parts demold faster. And unlike melt compounding, thermoplastic RTM can use continuous rovings and textiles and much higher fiber content. RTM also uses less expensive aluminum molds and can produce stress-free parts with thick and thin walls. Other R&D in nylon 6 RTM is being conducted at the University of Delft in Holland, and Cyclics Corp. in the U.S. has worked on PBT RTM made by polymerizing the company’s low-molecular-weight CBT oligomer in the mold.

A novel thermoset molding process, introduced at last year’s JEC show by Quickstep Technologies in Australia (U.S. office in Brighton, Mich.) is also being adapted to thermoplastic sheet. Quickstep slashes autoclave prepreg molding times by using lightweight composite or metal molds with flexible silicone bladders in each mold half. The bladders flood rapidly with a glycol heat-transfer fluid to heat or cool molds much faster than with liquid piped through solid tooling.

In the past year, Quickstep found it can also mold multiple layers of Saint-Gobain Vetrotex’s Twintex fiberglass/PP commingled woven fabric in its bladder-heated tools and demold a consolidated part 3 to 4 mm thick in just 10 min. To demonstrate the advantages of thermoplastic molding, Quickstep bought a folding boat maker in Australia (Flatout Boats Pty.) and plans to make Twintex panels itself and build boats.

Quickstep also modified its bladder-heated molds for deeper-draw thermoset and thermoplastic parts. Initially it could mold only relatively flat parts. Deep-draw parts require more complex bladders. Phenolic prepregs are being molded into deep-draw prototypes in Australia for the interior of an Indian railroad car.

RocTool in France (U.S. office in Atlanta) is adapting its patented inductive mold heating for rapid forming of large thermoplastic parts. RocTool has licensed its technology to Azdel Inc., a joint venture of PPG Industries and GE Plastics. Azdel has used this technique to mold a full-size car hood of glass-filled PC/PBT sheet at GE’s processing lab in Pittsfield, Mass. Class-A surface was reportedly obtained.

RocTool is also working to improve surface quality and cycle times of additional types of thermoset parts. Together with Krauss-Maffei, RocTool is developing an automotive rear shelf using induction-heated molds and K-M’s LFI (long-fiber injection) process for thermoset PUR composites. Material is deposited in an open mold at 100 F by a robotic mixing and glass-chopping head. The tool then closes and is heated to 212 F to cure the part, followed by cooling with water channels. Cycle time is down to 2.5 min from 6 min with conventionally heated and cooled molds.

Faster thermoset prepreg cycles through improved heating are also being sought by Voetsch Industrietechnik GmbH in Germany. It developed an industrial microwave oven, called VHM Hephaistos, with a hexagonal chamber that is said to apply more homogeneous heating than a round chamber. This year saw its first commercial application for curing carbon-fiber/epoxy prepregs. The result was said to be faster cycles than with conventional autoclaves and greater energy efficiency because all the energy goes into the part while the chamber stays cool. More uniform heating is also said to cause less degradation of carbon fibers. Chamber sizes are up to 1.8 x 2 meters. Metal tools reportedly can be used.

SMC needs no maturation

SMC prepregs normally must be matured for several days before they build enough viscosity to be molded. A direct molding process for SMC that doesn’t require maturation is being developed by a German consortium with government funding. Participants include Volkswagen, press maker Dieffenbacher, additive maker Byk, molder Menzolit-Fibron, fiberglass supplier Johns Manville, and the Fraunhofer Institute.

Direct SMC molding uses two twin-screw extruders, one to mix fillers and liquid resin, the other to add glass or other fibers and extrude the mixture into sheet. The sheets are heated for 1 to 2 min in a microwave oven and then are cut into charges automatically and robotically transferred to a compression mold.

Lasers show the way

At JEC, 3D laser projectors showed off new capabilities for composite quality inspection and assisting in ply layup.

SL Laser Systems in Germany (U.S. office in Charlotte, N.C.), showed its new laser projector, called ProCollector Mobile Laser, which works with a camera and laser projector. It indicates ply positions on tooling, captures dimensions of a part for coordinate measuring, locates holes, and documents quality for customers.

Z-Laser Optoelektronik GmbH in Germany announced its new “MPS” 3D mapping and laser projection system. It combines 3D camera measurement with laser projection. It compares specified vs. actual dimensions and can be used, for example, to help an operator position parts in a fixture for secondary operations or plies in a mold.

Assembly Guidance Systems introduced Micro LaserGuide with AutoFocus, reportedly the only laser projector on the market that can determine its distance from a part, allowing it to tune the laser automatically to project a sharp line.

Laser Projection Technologies launched its Targetless Laser Projector with optical feedback that can “see” part features in order to align a projected template. Mirrors receive diffused light reflected off a part and direct the diffused light into photo-detectors, which create a digital image of the part. Software then identifies and locates features like corners, holes, and fasteners. It works with any 3D CAD data to project a glowing template onto the work surface.

Virtek Vision International Inc., showed its LaserEdge 5.0 multi-tasking system, which allows one laser to project templates for multiple jobs on different work tables simultaneously. Virtek also introduced a small laser projector weighing 15.4 lb, less than half the weight of its previous smallest unit.

Visuol Technologies in France (formerly part of Techlab) relaunched its visual inspection products under the name Ondulo. They perform automatic inspection of parts for Class A surfaces. Instead of projecting striped patterns directly onto the part surface, Visuol displays the stripes on a screen and reflects them onto the part. Surface flaws are picked up by a camera as local distortions in the curved stripes. Visuol (represented here by EOS Technologies) has sold three systems in North America.

Read Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More

.png;maxWidth=300;quality=90)