Second- and third-generation family management: Doug Confer (center), CEO, co-founded the company with his father, the late Ray Confer. Doug’s son Bob (left) is president and daughter Connie is v.p. Behind them, an example of their chosen niche – a blow molder with 100-lb shot capacity. (Photos: Confer Plastics)

This year, Confer Plastics hit the Big Five-Oh. Privately owned by its founding family that’s now in its third generation running this blow molder of custom and proprietary parts, Confer Plastics has expanded in every way during its first 50 years of operation. It has grown to around $50 million in annual revenue, to 170 employees at its North Tonawanda, N.Y., plant and nearby warehouse facility, and to more and bigger accumulator-head blow molding machines — numbering 20 today — including one of the largest on the continent. The company is celebrating this achievement by reviving some of its once-popular but discontinued consumer products and by planning a big public open house for this fall.

A culture of innovation, family values and care for the environment has nurtured the company’s growth.

During its first half-century, Confer Plastics became known for its proprietary line of products “that allow families to get the most enjoyment out of their backyards,” as the firm’s website states: spa steps and cabinetry, swimming-pool steps and ladders, and lawn and patio furniture. Company co-founder Ray Confer invented the first all-plastic swimming-pool ladder in 1975. For its 50th anniversary, the firm is reintroducing a line of patio furniture discontinued five years ago — not because it wasn’t appealing to consumers, but because markups in the distribution channel made it unaffordable to consumers, according to company president Bob Confer, Ray’s grandson. He hopes direct sales by his company may be the solution.

“We make products that allow families to get the most enjoyment out of their backyards” – such as these pool steps and ladders (below).

Confer Plastics also has a solid record of innovation in custom products, which once accounted for as much as half its business, but are now about 30%. In the early 1960s, at a company he co-founded before Confer Plastics, Ray Confer co-developed the living hinge that reportedly is now used on almost every tool case and tackle box the world over. Previously, the cases had to be molded in two parts with metal hinges installed between them. Ray Confer’s invention was to compression mold a flexible solid hinge between the hollow case halves. Confer Plastics still molds some products this way.

The company also developed one of the first blow molded kayaks, which until then had been rotomolded and were relatively expensive. That changed when blow molding cut the production time from 40 min to 4 min.

Another innovation was the flexible funnel for adding oil or fuel to cars, trucks and tractors. These replaced metal funnels that would corrode over time and cause metal flakes to end up in the fuel tank. The patent from 1976 expired in 1990 and production was lost to Asian competitors, but Confer Plastics aims to re-launch it for its 50th anniversary. Bob Confer hopes that direct sales via e-commerce may make it competitive.

Other innovative Confer blow molded products over the years included the Reebok Step, still found in most gyms; fireproof safes, which required invention of an elaborate parison draping process that produces a multiwall structure to be filled with insulation foam and fire-resistant materials; as well as mannequins, birdhouses, and electronic voting machines. The company has numerous patents on blow molded male-female interconnects that enable easy assembly of their products with fewer fasteners.

Bob Confer says another golden-anniversary relaunch will be a blow molded sled from the 1970s that Confer made for a customer that is no longer in business. “We get inquiries every winter from people of my generation for these sleds for their kids and grandchildren, even though they haven’t been made for decades.”

Confer relies on its accumulated “tribal knowledge” of large-parts blow molding (like the hot-tub cabinet panels shown here) and the dedication of dozens of employees who have been with the company for 20 years or more.

An American Dream

The Confer Plastics story goes back well more than 50 years, when Ray Confer returned home to upstate New York from serving in World War II and took a job in which he dabbled in plastics chemistry and product design. In the 1950s, he achieved one of his life’s dreams by buying a farm, which he tended on nights and weekends with his wife and children. The farm helped him save enough money to achieve an even bigger dream of having his own plastics factory where he could turn his ideas into products.

In the 1960s, Ray Confer invested his savings and leveraged his home and farm to purchase plastics molding equipment and rent shop space together with a partner. They created a small company where they further developed blow molding technologies, the first of two such firms that Ray operated for the next decade. In 1973, Ray and his son Doug, then fresh out of college, founded Confer Plastics in North Tonawanda. It moved to its current location in 1986, which has been expanded three times since then with more and larger molding machines, assembly operations, warehousing and distribution.

“Our company is the perfect representation of the American Dream. Not just the dream of our family … but also the dreams of our employees and our customers.”

Ray Confer passed away in 1999, and his son Doug is now CEO. Doug’s son Bob is president and daughter Connie is v.p. and head of human resources.

“Our company is a perfect representation of the American Dream,” says Bob Confer. “It’s not just the dream of our family to have our own business and a farm (on which Doug still lives). It’s also about the dreams of our employees and our customers.” He explains that a company that was built by family lives by family values. “Everyone is treated like a part of a family, be they coworkers, suppliers, customers or the community at large. We believe in respecting others and having others respect us. You can see this in the number of employees (41 at present) who are members of the ‘20-year club’ – having put in 20 years or more at the company – and the number of customers that have been with us for decades.

In Bob’s view, Confer Plastics helps customers, especially smaller entrepreneurs and inventors, to realize their dreams by turning their concepts into reality. He adds, “Our specialty is taking short-run jobs that others won’t accept. For small to medium-size parts (up to 50 lb) we’ll mold as few as 500 parts, which is a one- to two-day run.”

Bob Confer feels that his products help consumers realize their dreams for family leisure activities. “We put smiles on people’s faces. We make products for outdoor recreation, mostly in or on the water – including frozen water, namely ice skating.”

For the community, Confer Plastics offers its commitment to local manufacturing and jobs that enable employees to realize their dreams for their families. “It’s expensive to operate in New York State,” Bob concedes. “The regulations are overwhelming. But we have a knowledge base here among our employees that enables us to do things others can’t.”

Confer Plastics offers internships and “shadowing” programs through which high-school juniors and seniors spend a day with an employee to learn about manufacturing careers. The company welcomes visitors from community organizations and students from local high schools, elementary schools and colleges. “It’s an eye-opener for them,” Bob Confer says, “to see tiny beads of plastic transformed into all these parts.”

Confer Plastics also serves the community through its attention to the environment. Doug Confer still lives on the family farm, which he has developed into a wildlife haven. Bob writes a weekly nature column for a local newspaper. And the Confer plant itself is surrounded by woods and a marsh that are homes to all sorts of wildlife, right within the city limits.

At the plant, the company has made significant investments to prevent pellet losses to the environment, to conserve energy and to reuse all production scrap in-house. All its products are made of HDPE with powerful UV stabilizers to ensure long life and colorants that contain no heavy metals to facilitate recycling.

Bob Confer says his firm has so far avoided using post-consumer recycle because of concerns about impurities that could compromise long-term durability and potentially risk the safety of consumers. “But our customers are asking about recycle, so we are looking into materials from chemical recycling, which I could see us using in the next year or two.” Chemical recycling, he explains, produces materials that are indistinguishable from virgin resin.

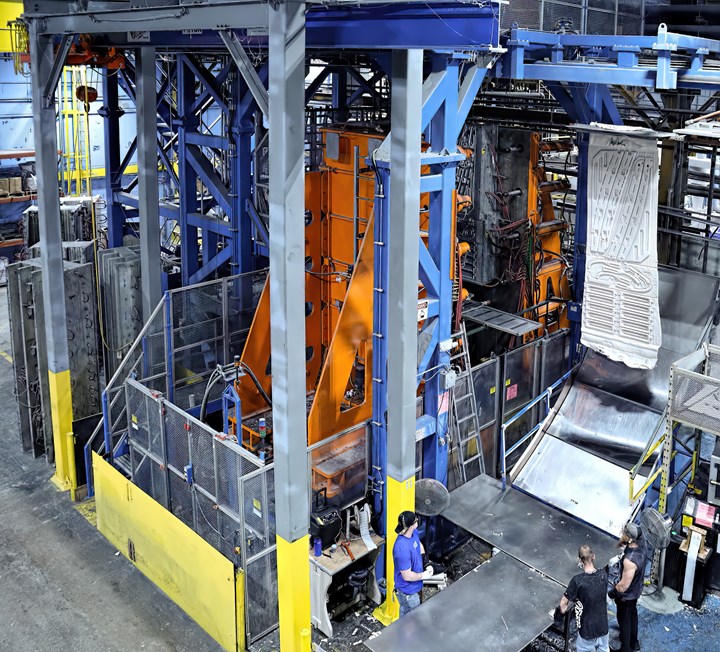

“The Beast” is Confer’s largest machine – and one of the largest blow molding machines in North America – with 145-lb shot capacity, shown here making a swimming-pool ladder.

A ’China-Proof’ Niche

For its first two decades, Confer Plastics made mostly parts in the 20- to 35-lb size range, and they had plenty of competition here and abroad. Then in 1993, Doug and Bob Confer decided, “We needed a way to beat China.” They concluded the answer was to move toward larger parts that would be uneconomical to ship over long distances, “because you’re shipping mostly air.”

Since then, Confer Plastics has moved more and more toward parts weighing 50 lb and over, a niche in which Bob Confer says his North American competitors “can be counted on the fingers of one hand.”

The firm’s 100,000-ft2 plant has 20 machines with shot sizes from 1 lb up to “The Beast,” a mammoth machine with 145-lb shot capacity and platen size of 168 x 70 in. It can make parts up to 15 ft long and 4½ to 5 ft wide. Bob Confer figures it’s one of the five largest blow molding machines in North America. The firm couldn’t find any one company to build a machine that large, so their team collaborated with companies in the U.S. and Taiwan to assemble this “Frankenstein monster,” as Bob calls it. “We needed it to mold kayaks, but the machine is designed for even larger products. Perhaps in future those could be holding tanks, septic tanks or wall structures.”

In his view, the key to success with big machines is knowledge of part design and process control: “What air pressure do you need to blow large parts? How much die swell should you expect in dropping a 12-ft parison? And how well do you know your materials — HDPE and HMW-HDPE?”

For Confer Plastics, a key asset is the accumulated “tribal knowledge” of large-parts blow molding. “When we put technicians through our apprentice program, we don’t consider them fully trained on large parts until they have five or six years’ experience.”

A good deal of that tribal knowledge pertains to mold changes. Confer’s tooling is built in aluminum, but the molds can still weigh up to 12,000 lb. The plant has overhead cranes for mold handling, and the Beast has its own dedicated crane. For a standard-size part – 20 lb or so – a tool change can take one shift with a team of two to three people. For larger parts, it can take two or three days, “mostly on the first shift to utilize our most skilled people,” Bob says. Head tooling changes also can take a whole shift.

Confer Plastics runs 24/6. In an average 24-hr period it can turn out around 330 swimming-pool ladders and 300 to 350 kayaks. Some jobs stay in the press for a month, some for up to six months. Custom jobs can require one to three setups on any given day.

Confer is rethinking part design reduce post-mold labor for trimming, assembling and packing parts such as this road barrier. Robots are also under consideration.

The Labor Challenge

Bob Confer says the supply-chain constrictions of the Covid pandemic years are mostly resolved, but other issues remain. One is volatile materials prices. “We used to requote products based on material costs two or three times a year. Now it could be every other month.”

The other challenge is labor availability, which has long been an industrywide problem but has become even more acute. Bob Confer has looked at the statistics and sees that public-school enrollments in New York State are down 25% to 38%, depending on region. “That means fewer workers. We’ve strategized to work around that by learning how to minimize the number of workers needed at a work station.”

Besides molding and trimming, the plant performs post-mold labeling and assembly. In the past it did foam filling for flotation and insulation, and Bob Confer says they will take it up again.

“Some of our custom products needed seven to 10 people for assembly, which is a burden today. So we told those customers that we would continue to do the molding that few others can do, but the customer would be responsible for assembly, which many people can do,” he says.

“We’re also looking at automation,” he continues. “We may bring in some robots in the future. Also we are rethinking part design to minimize post-mold labor. We’re looking at ways to provide for easier manual trimming and deflashing. Take, for example, a swimming-pool ladder. The mold has 30 cavities; that takes five or six people to trim, assemble and pack out. We revised the design with easier interconnects between the ladder treads and the wall for faster assembly.”

“We now have computer screens at workstations instead of paper documentation for quality-control procedures or task lists. And we’re tracking cycle times, which are posted on a large computer billboard, so any lags are addressed immediately.”

He adds, “We’re doing other things to streamline our operations. We totally remade our purchasing to be more data driven. We scan a barcode when we take a component – a drive motor, belt or screws – out of inventory. We’re making our own videos for training and for virtual weekly meetings with video reminders on safety and quality. People seem to retain the information better than merely with verbal communication.”

In addition, Bob says, “We now have computer screens at workstations instead of paper documentation for quality-control procedures or task lists. We use a weigh scale for every part – the operator weighs the part as a quality check and to make sure we are not using excess material. We’re digitizing setups to record how long they should take. And we’re tracking cycle times, which are posted on a large computer billboard, so any lags are addressed immediately.”

What’s more, “We’re implementing predictive maintenance, so we will know how long a belt on a grinder can last, or a drive motor.”

As for that 50th anniversary open house – it will be Sept. 20 and “All machines will be running.” Bob Confer says. He’s expecting 600 to 700 visitors, who will get refreshments as well as souvenir molded products.

Related Content

Paulson Training Acquired

Certus, a technical skills training business and portfolio company of private equity firm Ridgemont Equity Partners, has acquired the plastics processing training business founded in 1981.

Read MoreGraduate Students Simulate Packaging Designs with Development Software

Software from Nova used in packaging engineering course.

Read MoreSilicone Elastomer Course Returns

After completely filling the classroom last year, the Silicone Elastomers Technology and Fabrication course returns to Pomona, Calif. Jan. 31-Feb. 3.

Read MoreMold-Change Time Targeted with Training, Technology

Engel is offering technology and training to molders to help them optimize their mold-changing process.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More

.png;maxWidth=300;quality=90)