Get Ideas from IMDA Award Winners In IML, IMD & In-Mold Electronics

Winners of the annual IMDA Awards Competition highlight aesthetics, functionality, sustainability—and even COVID-19 protection.

The latest winners of the annual In-Mold Decorating Association (IMDA) Awards Competition comprise about a dozen applications that showcase the best in in-mold design and technical achievement. This year’s competition added new categories to recognize innovations related to sustainability and the COVID-19 pandemic.

The winners are parts that were produced in 2020 or slated for release in 2021. They were chosen for overall design and complexity; integration of the in-mold element into the part or package; functionality; and innovation in the use of materials or processes. Manufacturing difficulty and complexity of the part, label, design or mold were also considered.

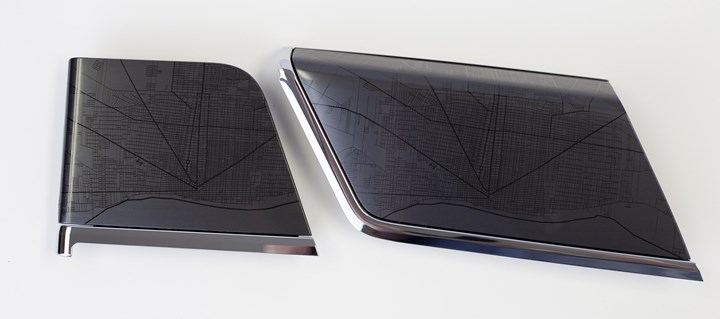

Best IMD in Durable Consumer Goods

The user interface panel from GE Appliance, molded by Eimo Technologies, Inc., Vicksburg, Mich., impressed the judges with the number of decorative and functional elements contained in one part. The customer required a premium look for the product, which meant incorporating all the cosmetic needs (chrome, high gloss, UV hard coat and hidden-until-backlit LED areas) in a single IMD film, supplied by Nissha. Without IMD, using all those individual elements would have been too expensive. This part’s geometry necessitated early supplier involvement to ensure no sink marks or knit lines.

This was one of two categories in the Awards Competition for which the judges designated an Honorable Mention entry. This was the City Map door appliqué for the Ford F-150 XLT Sport Series pickup truck. Thermoformed by CS Manufacturing, Inc. in Ionia, Mich., for Faurecia, using an inline film-insert approach, the design on this part is a mechanically brushed, metalized foil from Kurz overprinted with a roadmap graphic of the Detroit downtown area. Kurz UV-curing screen inks helped preserve the appearance and haptic touch of the roadmap line density during forming. Complex part geometries with deep drafts and radii posed a challenge to avoid stretching the image.

Best IML Blow Molded Package

For the Miracle-Gro Plant Nutrition Granules, the judges appreciated the shelf impact provided by the striking color choices and size of label with 100% ink coverage. IML ensured that the package is waterproof for outdoor storage, but consumer safety was also a factor. The contents are potentially harmful, so it was critical to use a label that would not come off. IML was also particularly suited to this product, because the bottle gets dusty during filling, making it difficult to label afterward. The large label (from CCL Industries) required design of special tooling. The bottle was blow molded by continuous extrusion for Scotts Miracle-Gro Co. by Silgan.

Best IML Package—Large Container

The Storm Shield exterior paint pail was molded in-house by German Lebanese Co. for Industry (GLC) in Egypt. Its CEO Anwer El Hout credits IML not only for an eye-catching design but also for creating a result that’s difficult to copy—“A factor that’s paramount in the paint world due to the proliferation of counterfeiting,” he says. The labels (from MCC Verstraete) used metallic foil and Matt + Spot HighGloss, allowing a color gradient that can be difficult to achieve.

Best IML Package—Small Container

Best IML Package—Small Container

This margarine package, injection molded captively by La Fabril of Ecuador for its Girasol brand, replaced a previous thermoformed version with plastic, sleeve and carton. The new thin-wall, monomaterial design also replaces an aluminum-foil tamper-evident seal with an optimized tight closure system. With IML (label from Creaprint), the overall results is a more efficient and versatile production process, a product with superior look and feel, and significant weight reduction without compromising functionality. It now is the top seller in its category.

Best In-Mold Label—Aesthetics

Best IML Aesthetics

This food container, molded for Siqalo Foods (Pty) Ltd. by Marcom Plastics in South Africa, achieves a shiny, copper bronze brick using metallic foil from MCC Verstraete. Metallic labels can be difficult in IML applications where static charge holds the label in place during molding. Because full metallic labels are conductive, they dissipate static charge, which can result in label misalignment during injection. For this product, the design parameters were amended to ensure that the foiled area did not exceed a specified limit.

Best In-Mold Label—Technical

Best IML—Technical

This yogurt container features a “smart” label from Korsini (plants in Turkey and Italy), which has a code embedded in the design in a way that the eye does not easily detect. However, a consumer with a cell phone can interact with the label and link to a URL via an app. This allows the consumer to check the origins of the product and allows retailers to speed checkout at the cash register with fast and easy price retrieval. Embedding the code in the printed design presents a challenge, since the code must not be corrupted during label application. The tub was molded by Berry Superfos Besançon in France for Milchwerke Schwaben eG in Germany.

Honorable Mention: IML—Technical

An Honorable Mention was also granted in this category for a prune container molded by Teknopak A.S. in Turkey for Efe Ege Zeytincilik Ltd. Sti. It has an oxygen-barrier label from Korsini, giving the product long shelf life. With its clear lines the label design allows the molder to check the label position with cameras during molding. Slight overlap of the barrier film is vital to eliminate any gap that would allow oxygen entry. The judges also appreciated the use of a partially clear label for a product that typically is packaged in metal cans.

Innovative Use Related to COVID-19

This demonstration part also won in the category for Best Use of In-Mold for a Prototype Product or In-House Promo. It showcases Kurz’s Biofense technology, which reduces or eliminates bacteria on plastic surfaces (the company makes no claims for viruses). This IML film is said to ward off bacteria for the life of the product and to withstand the harshest of cleaning and hygiene requirements. What’s more, this part utilizes high-resolution printing with specialized vacuum metalization that provides a glossy, formable surface suitable for parts with complex geometries, deep drafts and radii. The metalization is nonconductive to prevent interference with IML molding.

Sustainable use of In-Mold Processes

Sustainable use of In-Mold Processes

Both the paint pail and the label from MCC Verstraete are PP, so this monomaterial product is 100% recyclable. What’s more, the pail itself is molded from 100% PCR plastic by Dijkstra Plastics in The Netherlands for Koninklijke Van Wiljhe Verf. Because the PCR combines material of different colors, it is not possible to produce the white pail that is traditional in the paint market. So white printing on the IML is used to mimic that look on a dark-gray pail.

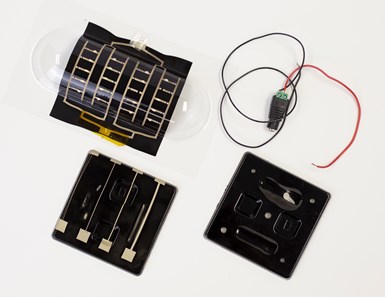

Best Use in In-Mold Electronics (IME)

Best Use in In-Mold Electronics

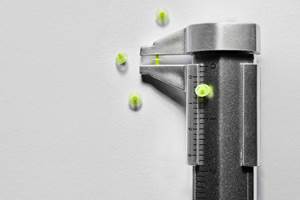

NAMICS Corp. of Japan highlighted its Kinomec functional inks, which offer depth of draw and electrical conductivity for IME. These inks reportedly can withstand deep-draw thermoforming and injection molding without losing conductivity.

Judges’ Choice Award

Judges’ Choice Award for Multifunctionality

The judges were impressed with the multifunctionality of this vegetable-oil bucket from Frylite of Ireland, molded by Dijkstra Plastics of The Netherlands. Clients return used oil in the same buckets, allowing Frylite to clean and refill the same bucket up to five times. However, the company noticed buckets disappearing, attributed to the ease with which the previous labels peeled off. Now with a reverse-printed IML PP film from MCC Verstraete, the print is protected in transport, handling and high-pressure washing, with no fading of the three-color image.

Related Content

In-Mold Labeling Applied to Medical

In collaboration with multiple partners, Arburg will showcase IML for centrifuge tubes at Fakuma 2023, eliminating printing or other downstream steps.

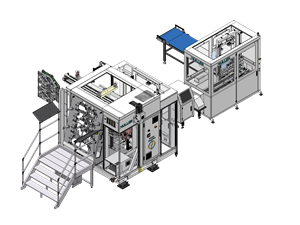

Read MoreNew In-Mold Labeling System Launches at K 2022

Muller Technology’s IML production cell will produce a round container in an 8-cavity mold with vison inspection and downstream automation.

Read MoreCompletely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreSlimmer All-Electric Press Debuts

A slimmed-down version of Engel’s all-electric, e-mac injection molding machine is among eight displays, which also include LSR micromolding, quick mold changes and a cube mold.

Read MoreRead Next

In-Mold Labeling Automation System for 5-Gal Pails

Muller’s new IML system boasts major improvements over standard pressure-sensitive and printed systems.

Read MoreDigital Watermarking Consortium Advances Technology for Sorting & Recycling Plastics

Europe’s Digital Watermarks Initiative HolyGrail 2.0 gains new members and advances to Phase II pilot projects.

Read MoreOvercoming IML’s Challenges To Reap Its Rewards

In-mold labeling has advanced dramatically over the past 20 years, but mostly in Europe. Here is what you need to know to bring IML to your operation.

Read More

.png;maxWidth=300;quality=90)