Injection Press Converts to Injection-Blow

A simple way for injection molders to get into blow molding of small containers for food, beverage, cosmetic, and pharmaceutical applications has been introduced through a collaboration of Engel Austria, the injection machine supplier (U.S. office in York, Pa.,) and Italian injection moldmaker Cantoni S.r.l.

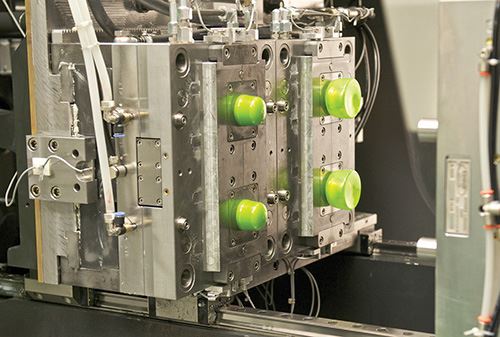

A simple way for injection molders to get into blow molding of small containers for food, beverage, cosmetic, and pharmaceutical applications has been introduced through a collaboration of Engel Austria, the injection machine supplier (U.S. office in York, Pa.,) and Italian injection moldmaker Cantoni S.r.l.. The “inject2blow” system uses an Engel tiebarless machine—either a victory hydraulic or e-victory hybrid model—together with a Cantoni sliding-plate mold and an Engel viper linear robot to demold the parts.

The sliding mold injects two preforms in the center section and then slides alternately to the left or right to blow the parts, while fresh preforms are being injected. Bi-orientation (stretching) option is available. A two-cavity demonstration system can produce wide-mouth jars in a 2+2 cavity mold with a cycle time under 14 sec. The system uses much less floorspace than a conventional rotary injection-blow system. Also, since the system is operated by the Engel CC 200 machine controller, injection molding operators reportedly don’t have to learn a new process. They will simply be guided through the integrated injection and blow molding steps by the familiar Engel controller.

Related Content

-

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

-

Is There a Better Way to Heat PET Preforms for Stretch-Blow Molding?

Is near-infrared (NIR) heating better, faster and more energy efficient? So far, only two machine builders are making such claims for NIR in place of standard mid-infrared preform heating, though their systems appear to be well accepted. Meanwhile, an altogether different alternative is in the works.

-

Multilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.