Everywhere we look as professionals, we are seeing and hearing more about “Industry 4.0” and other digitally connected systems. These new systems are more than just the “next best thing”—they represent a new model for manufacturing and, for some people, a new way of working. As manufacturers begin to integrate these new systems, many questions arise on how they impact an organization and how organizations should adjust to that impact.

My own company faced the most important and urgent question being asked today of Industry 4.0 systems: “How do I introduce this to my own plastics factory?” When we developed the Smart Attend production monitoring system—initially for our own use—at Axiom Group Inc., a Canadian automotive injection molder, we had to overcome some of the biggest challenges that an Industry 4.0 system introduces. One of these challenges was driving this change via new processes throughout all departments, starting with the factory floor. We quickly learned that not only are people resistant to change, but it required constant training, constant promotion of the software, and a near endless supply of answers to questions that were constantly being asked. This is because an organization is still made up of people from all different backgrounds and experience, and it quickly became a foolish mandate to assume that everyone learns the same way.

Before we embarked on an Industry 4.0 solution, we knew that we needed something. We were losing thousands per month in just unexpected downtime and lost value. We knew that our paper-based systems caused us to be reactive (and far too slow at it) instead of proactive. We knew that each day we left the office, we banked on the hope that our presses continued to produce parts for us all through the night. What we didn’t know was how to improve our processes further, beyond the continuous-improvement efforts we’d already been making every year we existed. Smart Attend was the result of us sitting in a boardroom and discussing solutions that didn’t yet exist in the industry.

Once we overcame the development hurdles, introduced the technology, and had the entire workforce bought in, the results were impactful. Machine downtime was cut in half; we saved nearly 30 hours per week just in collecting data manually over multiple resources; and most of all, we could now solve our problems instantly through real-time root-cause analysis rather than reacting to it hours later. We didn’t have to wait a week to decide—decisions are now made as quickly as the need arises and the results have never been clearer.

But it didn’t happen overnight, and our biggest learning curve came from introducing this type of system across the organization and its personnel. With both our domestic and international clients, the lessons we learned helped us integrate this technology safely and effectively in every plant running the Smart Attend platform.

In this article, we’ll provide a ground-floor view of how we implemented our own production monitoring system, and how we had to overcome numerous challenges that the rest of the industry is currently experiencing. Challenges such as:

• Managing employee trust in the system;

• How to introduce it on the plant floor;

• Managing long-term expectations.

HISTORICAL CHALLENGES

For decades, manufacturers have used paper-based systems for monitoring production metrics, for scheduling production runs, for reviewing performance and throughput. Such manual-based production reporting has allowed companies to look elsewhere for continuous improvement, but has also created a mantra of “Why fix what isn’t broke?”—thus making the argument for a 4.0 system more challenging than initially expected. So, when a company begins the process of integrating an Industry 4.0 system, it’s never going to be a completely smooth transition, and at times for many managers, it appears to be a battle that may appear more daunting than previously anticipated.

But it doesn’t have to be daunting or even overly ambitious. It will take some planning and execution. Human beings are creatures of habit, so asking them to change the way they’ve been operating for years will require a careful thought-process, working with the system supplier on building strategies, and implementing these strategies to monitor their effectiveness. After all, your staff are the ones who will be using these new systems to become more effective at their jobs; you need their buy-in to ensure the system is being used to its fullest potential.

As many suppliers offer new digital gateways for managers to access their data, it’s devastating for a management team to fumble with attempting to introduce five different Industry 4.0 systems that are all burying them and their team in information. Any system must centralize all of these data points and simply have one goal: to make the lives of the organization’s employees easier through speed and accuracy. If too many systems are introduced all at once, it will be nearly impossible to get the buy-in from staff.

EMPLOYEE TRUST IN THE SYSTEM

Let’s start off with one of the most common challenges: How can you ensure that your employees are trusting the software?

It seems like a no-brainer: “Why wouldn’t they trust it? Isn’t the data coming right from the machine?”

This is a question we’ve heard before, and it’s something we’ve had to address many times. Here’s the funny thing about people that we’ve experienced: When they expect the software to display what they believe their production metrics are, the buy-in is simple. When the software displays what the plant is truly doing, their trust in the system drops because it doesn’t line up with their expectations.

It’s a simple question to ask where is the greatest margin for error. Is it relying on information produced by a person or by a machine? Who is more likely to make the bigger mistake?

People have the tendency to turn to denial when presented with information they didn’t expect. When we showed our own workers that the cycle times were at only about 60% of the efficiency level required over the night shift, the blame was shifted to the Smart Attend system because, after all, “We’ve been running like this for over a year now!”

This type of behavior has to be managed appropriately at the employee level. There wouldn’t be a reason to change data-collection systems unless you’ve identified it’s a gap in your processes. It’s important to always remember that people have various different levels of understanding when it comes to technology; and if they have a system pushed onto them without getting their buy-in first, there will be some resistance.

But reality is reality, whether you choose to buy into it or not. Machines and machine monitoring software have to produce information from somewhere, and that somewhere comes directly from the machine’s sensors and electronics. It can be a difficult pill to swallow, but a culture built on continuous improvement means that when the hard facts are displayed, they have to be taken in stride.

At Smart Attend, one of the very first things that we tell our customers is to not use this system as a “negative tool” to find out what they’re doing wrong, and instead pitch it to the employees as a positive addition to the shop floor. We’ve seen that it’s easy for shop-floor employees to get the wrong idea about this tool if presented in a negative light, such as:

• Introducing it to the floor as a way to monitor employees 24/7;

• Instilling fear through the “Big Brother” approach to employee surveillance;

• Removing trust from the employees and relying purely on data to reprimand them.

In order to receive the buy-in from the production floor staff, the system has to be sold to them primarily as a management solution that is designed to make the lives of employees easier. Leveraging this with profit-sharing systems, performance-based incentives, and other rewards helps ease some of the “Big Brother” fears and allow all levels of staff to benefit from the performance gains.

Removing time-consuming paper-driven systems that rely purely on manual data collection helps managers re-allocate resources, and allows employees to focus on more value-added jobs. More so, it helps identify the waste that these historical processes have created, and machine-driven information helps improve accuracy, speed, and overall performance improvements across the organization.

Nonetheless, change is difficult. Many times, managers will hear from staff, “That’s not accurate” or “That’s not correct” as employees react to the new systems. Whether or not the accuracy of the information is under question from staff, those employees who are less than enthusiastic about the system will constantly drive a wedge into the new technology, and without that being controlled immediately, it has the potential of spreading like a cancer across the organization.

One simple fact: It’s easier to put blame on a technology that is new to a production floor rather than have people accept responsibility. Corporate culture really does play a big component in a system like this, and a culture of blame direction will always be more less hospitable to change than a culture built around continuous improvement.

It’s imperative that staff, managers and other members of the organization understand that these systems work simply by receiving signals and data from equipment. If the machine did it, then the system will display that accordingly.

Of course, receiving employee buy-in for the system has to go beyond just telling them to trust the system. They have to begin using the technology to get beyond their current roles. They have to become as integrated into this technology as management is, and must become actively invested in it as part of their core job.

INTEGRATING THE SYSTEM WITH YOUR STAFF

Rolling out an industry 4.0 system takes careful time, planning, and execution. Much like any major change, some people are less enthusiastic about changing processes than others, and it’ll take constant reinforcement from the management team in order to adopt the technology. Creating incentive programs that rely on successful change brought about through the new system are a powerful way to incentivize adoption to production staff. Reinforcing the positive elements of the system and mitigating any “Big Brother” fears are among the most important elements of integrating the technology.

Some examples of incentive programs we’ve included are:

• Gift card and monetary rewards based on performance-based improvements;

• Management bonuses for root-cause identification and improving time-to-resolution through using the new system;

• Incentives based on solving issues remotely through real-time and remote data access.

Another powerful change we’ve recommended is bringing production meetings from the boardroom right to the shop floor. Axiom no longer holds its meetings centred around a board table; real-time data is brought up in an instant and discussions happen with the production staff right in the production environment.

PHASED INTRODUCTIONS

Phased introduction of a new technology is effective for one simple reason, it drives change at a pace that allows for all questions to be answered before rolling it out to the entire staff. One of the biggest risks that companies face when rolling the system out too quickly is that the “Change Management” aspect of the technology is lost among employees. There will be questions, some will sound repetitive, some will have simple answers, others will not. The role of the manager is to drive the business in the most effective ways possible, and integrating this system will give employees tools they’ve never experienced before.

As our industry becomes increasingly focused on squeezing out efficiencies in every area, time is constantly the biggest waste within every organization. An Industry 4.0 production monitoring system can completely eliminate time allocated for collecting production metrics and produce vastly more accurate information to help managers identify and root-cause production issues as they’re happening. It’s your job to ensure that you see the ROI, and the only way to experience that is by having your staff utilize the new tools at their disposal.

Phase 1: Start small, think big. Work with your system supplier and build a strategy with them for a successful integration. The supplier alone can only do so much, so it’s up to you to ask the demanding questions:

• How do I translate the value to my employees?

• What effects will this have on our IT infrastructure?

• How do I ensure the data is accurate?

Translating the value to the employees comes from building an action plan with the supplier that includes key objectives to focus on from the management point of view, and building in new KPIs (key production indicators) and measurables at the employee level. Starting simply at first, begin to assign new duties to employees and reward them accordingly for managing their slice of the new software. If it’s maintenance resources, for example, show them that the system can alert them when a machine issue springs up, promoting faster resolution time through instant problem identification.

Things to keep in mind:

• Show the time-saving value to your employees;

• Promote new incentives based on metrics collected through the system;

• Reward problem identification sourced through the software

Phase 2: Bring the department heads up to speed on the new tools and provide them access to the simplistic functions first. Champion the system internally and be a source of knowledge for them. Leverage the relationship with the system supplier but don’t rely on them for every answer, they don’t know your staff like you do.

Some key tactics to enforce:

• Assign a champion internally who will help manage the system from an administrator perspective. This person should be the primary contact with the system supplier.

• Build your rollout team(s) and set specific KPIs that begin small. For example, build logins for each member of your department. Ask each department to collect reports through the new system.

• Slowly enforce more complex KPIs and build a plan to obsolete any old processes. Your system supplier should be aware of these processes and help guide this strategy.

• After one to two months, your department heads should be fully ingrained in the system and not require further training.

Phase 3: The full rollout. Now that your department heads have bought into it, it’s time to generalize the rollout of the system across the company. Assign each department head as the specialist for their aspect of the system, and monitor their progress of integration with their staff. Continually build reports, leverage new information, and ask each staff member how they are using the system.

Work with the supplier to relay active feedback and fine-tune each aspect of the system so that it becomes further ingrained into the everyday work life of your staff.

Once rolled out, have the supplier assist in determining the ROI using your own data, and present the improvements to your staff. Take this opportunity as well to factor in your own staff’s KPI’s and leverage their success through the system. This way, people will now have the power to actively use this data for their own job performance and gains in their day-to-day work life.

Important strategies to maintain:

• Daily stand-up meetings (if applicable) should be focused around the system to help bolster a sense of its importance to management.

• Unfavorable trends should be identified immediately through the system and discussed as a team. Resolution and impact should be identified through the system as well.

• Reward employees who help identify these trends to management and create a positive conversation around the system. Use “Gamification” (game dynamics) for employees to reach goals and reward them accordingly.

• Above all else, never use the system to publicly shame anyone. Always keep any disciplinary action behind closed doors. Public shaming may lead to a negative perspective on the new technology.

• Regularly ask staff for their thoughts on the system, and ensure that it’s being updated and managed accordingly. The more integration you have, the higher value you’ll experience.

MANAGING LONG-TERM EXPECTATIONS

As a manager, the key difficulties in your job are going to be managing employees’ expectations and confidence in the system in the short term. Then how do you maintain employee confidence in the system for the long term? Ultimately, the Industry 4.0 system exists to create visibility and efficiencies that didn’t exist before. It’s a tool that must be used to the fullest potential in order to make the investment worth it.

People are habitual creatures, and creating new employee habits in the workplace can be tricky work. It takes continuous efforts from management enforcing the system, highlighting gains (or pains) through the software, lead hands must integrate with the system and continually use it to enforce new production strategies, and the system must be used in management meetings to illustrate historical trends. Eventually, it becomes part of everyday life.

ABOUT THE AUTHOR Max Preston is general manager and customer process designer for Smart Attend, a real-time Smart Manufacturing solutions provider based in Aurora, Ont. Max is experienced in designing and integrating Smart Manufacturing solutions on three continents and is trained in managing profitable molding operations. Sitting on the Future Leaders in Plastics council on the Plastics Industry Association (PLASTICS), Max also helps educate and discuss various challenges with Industry 4.0 solutions throughout the industry and has formed partnerships with other suppliers. Contact: (866) 210-9630, ext. 105; max.preston@smartattend.com; smartattend.com.

Related Content

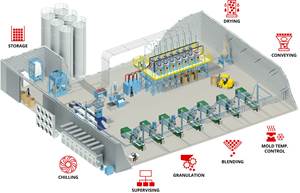

A Cost Saving Modular Approach to Resin Drying Automation

Whether implementing a moisture-sensing closed-loop system for a single dryer, or automating an entire plant, technology is available to take the guesswork and worry out of resin drying. Using a modular approach allows processors to start simple and build more capabilities over time.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreHow Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

Read MoreEnsuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

.png;maxWidth=300;quality=90)