Precision Extrusion Puller/Cutters Designed for Medical Tubing

Sponsored ContentNovatec’s Bob Bessemer is at it again with a new line of extrusion puller/cutters designed specifically for the rigors of microbore medial tube processing.

Share

Read Next

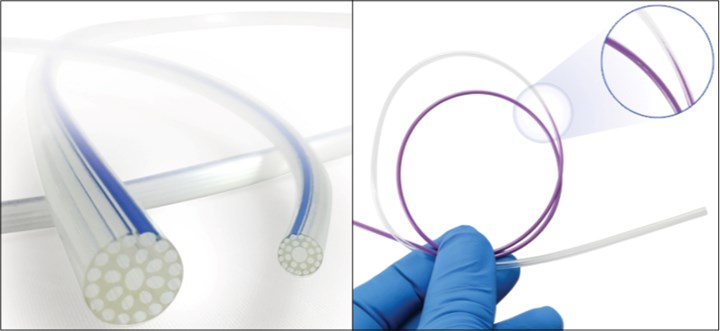

Extruding microbore tubing for the medical industry is demanding. Tolerances can be measured to ten-thousandths of an inch. Achieving precise pulling pressure and speed is critical. Materials can be difficult to cut cleanly and accurately. And, it all must be done in an extremely clean environment. So Novatec’s Bob Bessemer knew what he was up against when he set out to design the perfect puller/cutter for extruded single- and multi-lumen microbore tubing.

The Bessemer Rx-SmartMED Micro-Medical Puller/Cutter comes cleanroom ready with stainless steel construction for easy wipe down.

But Bessemer didn’t do it alone. He regularly consulted with elite extrusion experts such as Larry Alpert—a long-time medical-tubing processor who now runs his own consulting company, Med1Extrusion—to get a thorough understanding of equipment needs from the user perspective.

What they came up with is the Bessemer Rx-SmartMED Micro-Puller/Cutter Series that has been designed from the ground up with an intense focus on plastics processing requirements for medical tubing. “Key features have been fine-tuned to offer the most precise, easiest to clean, most efficient puller/cutter available on the market today,” Bessemer says. Available in three models, the puller/cutters can be configured with puller contact areas of 1 × 6 inches, or 1 × 12 inches.

The new puller/cutter is part of Novatec’s Bessemer Rx-SmartMED Series of downstream extrusion equipment that also includes a new line of water and vacuum tanks introduced last year. Both the puller/cutters and tanks are designed for cleanroom medical extrusion operations.

This overview of the Micro-Medical Puller/Cutter Series explains how the design is optimized for medical microbore tubing.

Precise & Adaptable Tube Pulling

The puller is perhaps the most important component in a downstream extrusion system for microbore tubing, and precision performance is critical. As Bessemer puts it, “We wanted to make sure that we had the most precise puller because the puller is the heart of the extrusion line. It's critical that we pull that tube through the cooling medium at a precise level because we're not just holding thousandths, we're holding tenths of thousandths today.”

One of Bessemer’s pet peeves about downstream extrusion equipment is using a hand crank to set the belt gap. This low-tech approach introduces an unnecessary process variable that is virtually impossible to accurately control. So Novatec replaced the dated hand crank with servo-positioned belt drives on both the upper and lower booms. This enables an extremely precise setting of both the zero position and the gap, measured in thousandths of an inch. The settings can then be stored in the program recipe and password protected to ensure repeatability with each resetting of the gap.

Linear slide bearings are used to guide the positioning of the upper and lower drives so that extremely accurate parallelism of nearly one-thousandth of an inch can be maintained across the entire contact area of the belts. This alleviates the crushing or slipping that can occur when belt contact planes are not parallel to one another.

The puller unit offers extremely accurate performance and quicker and easier setup.

The puller heads can be fully retracted for easy walkthrough setup. The clear polycarbonate covers open to provide full access to the unit so that a belt change can be executed in two to five minutes. This ready access also makes it easy to clean up the unavoidable wraparounds that sometimes come with stringing up tacky small diameter tubing.

A laser gauge can also be integrated with the control system that can adjust the puller gap in real time to compensate for any variability in the tube diameter. As Bessemer describes it, “When you start up, you’re basically pulling a thread at zero gap. As the tube comes up to, say 25 thousandths, and we’ve set a crush differential of 5 thousandths, the gap will automatically adjust to 20 thousandths. And it will follow the tube up and down, always maintaining the same crush and slippage parameters.”

The belt and drive systems are also designed for precision. The upper and lower belts are driven by independent servomotors, which enable extremely accurate synchronization with virtually zero backlash. Rather than using the typical poly V-belts or timing belts, the puller/cutter uses precision flat belts running over a triangular set of rollers. Larry Alpert notes that the flat belts will be much less inclined to pick up particulates, and that the roller system is designed for accurate tracking. The tensioning system not only pulls the belt but can also pivot to precisely align the belt track. Even the thickness of the belts is precise, to a thousandth of an inch, which further enhances process accuracy and repeatability. Three sets of belts are included with the unit including sponge, white nitrile and a dual-layer belt with sponge and silicone combined.

Cutting a Wide Range of Materials

The fully integrated cutter unit can handle a wide range of tubing configurations and materials.

As Alpert points out for medical applications, the cutter must be able to handle a wide range of tubing configurations and materials: “For instance, one day you may have a typical polyethylene dilator that will be rigid, have a larger OD, thick wall, and small ID. The next job may be a very flexible polyurethane that most people just can’t cut inline. The ideal situation is to be able to handle them both with the same cutter.”

For this reason, the cutters can be fitted with a variety of blades from 0.015" wide down to 0.004". The standard cutter arm rotates at up to 1,500 RPM, which is about a third faster than most cutters, and by adding a flywheel the arm can go up to 3,000 RPM.

Cutter bushings are pre-gapped and include a forced air feed system to keep the cutting area free of material.

The cutter bushings, which provide the slot the blades pass through for the cutting process, are pre-gapped and include a forced air feed assembly to prevent jamming and to enable the cutting of smaller, more flexible tubing that couldn’t be cut inline before.

The combination of many blade options with the ability to precisely achieve the desired surface speed at the point of blade contact enables the unit to cut almost any type of tubing to very accurate and repeatable lengths, even at high line speeds.

Optimizing the String-Up Process

Stringing up a new run on a combination puller/cutter can be a time consuming and frustrating task, especially with small OD tubing. To better enable this process, Bessemer’s design has the cutter unit mounted on a carriage that slides laterally away from the puller to create a large workspace between each component for setup functions (see video below). Says Bessemer, “Operators need a lot of distance in here for their string-up process when the material is coming through or for a rigid part where you need more room. So we gave them enough space for that and for other setup tasks such as changing blades.”

This video shows how the cutter station can be separated from the puller unit for easier and quicker stringup as well as other setup and maintenance functions.

Novatec also changed the position of the cutter motor so that the cutter guides are much easier to access. This created enough space to add a blade lubrication tray that eliminates the need for the type of blade whetting systems used in the past that, as Alpert puts it, “were breeding grounds for particulate.”

The “walk-through” guide system combined with easily retractable puller heads facilitates quicker setup.

The puller unit also includes a “walk-through” guide system rather than having to feed the tube through rollers, as is typically done. This method is safer and a much easier way to thread sticky low durometer materials that tend to roll up and down the guide system. Also, the puller unit is slightly overhung on the machine base so that during stringup material does not lay on the machine table.

Intelligent Software Control

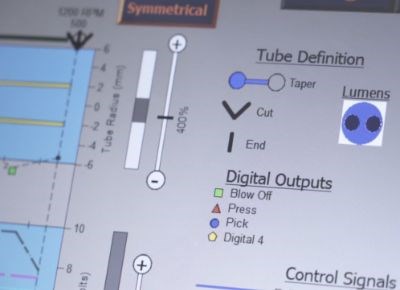

A great deal of thought has gone into puller/cutter software to make it easy to use yet still offer optimized recipes designed especially for medical microbore tubing. A number of these functions capture the knowledge gained through Larry Alpert’s many years of working with difficult medical tubing applications.

Operators make selections from the process- and product-specific menus with many complicated functions preprogrammed, such as managing acc-dec profiles for tapered tubing.

Through various intuitive drop-down menus, an operator inputs information including extruder size, material, durometer, throughput, distal and proximal dimensions, transition lengths, desired line speed, whether the product is single-lumen or multi-lumen tube, and whether it is symmetrical or non-symmetrical taper tube. Also, operators can program the die and pin size they plan to use, and the program will determine if the settings will work. If the intended die and pin combination does not work, the program will make a recommendation.

The control can also keep a traceable lot history record that details all data generated throughout the run. This is particularly important for critical medial parts.

Like the Rx-SmartMED Series tanks, the Micro-Medical Puller/Cutters are next-generation IoT-enabled, leveraging technology from Siemens and MachineSense, a subsidiary of Novatec and a Gold Partner in Siemens’ MindSphere Partner Program. MindSphere is the cloud-based, open IoT operating system from Siemens that connects products, machine systems, and plants. This helps enable businesses to harness the wealth of data generated with advanced analytics that provide:

- Secure connectivity and data management

- Out-of-the-box and custom analytics that drive operational insight

- Real-time machine health monitoring that significantly reduces unplanned downtime and maintenance costs

- Insights from machine data that enhance workflows, interoperability, and facilitates new business models

Add up all the features of Novatec’s new Puller/Cutter Series, and you’ll find no equal specifically designed for processing medical microbore tubing. Contact Novatec for more information on the Bessemer Rx-SmartMED Micro-Puller/Cutter Series or download the datasheet now.