Precision Molding Without a QC Department?

At Prism Plastics, quality is baked into every step of the process. The result: 1 billion parts per year with a defect rate less than 1 ppm.

“Variation is the enemy.” That’s the mantra of Prism Plastics, according to Jeff Ignatowski, director of sales and marketing. “We throw as much technology as possible into the process to eliminate variation in every step, from the quoting stage on. We won’t even quote on a project that looks like it will have too many uncontrolled variables.”

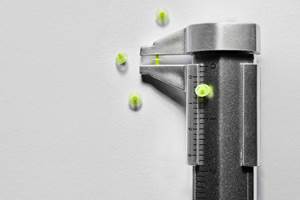

Strict control of product quality is not only an obsession at Prism Plastics, it’s a necessity. The vast majority of the 1 billion custom parts it injection molds annually are tight-tolerance, functional or critical-use components for automotive applications, many of them safety related, such as for seatbelt or airbag mechanisms. Many parts have tolerances from ±50 microns (0.05 mm) down to ±5μ or less. Example: an Ultem PEI airbag component with a ±3μ tolerance.

Such tight control, Ignatowski explains, cannot be achieved by old-fashioned “mold and sort” quality assurance: “Quality has to be embedded in the process.” And by “the process” he means every activity from quoting through tool design and process development to molding parts and packing them in a box. Yet there’s one quality- related activity that you’ll find in almost every molding operation except this one: Prism Plastics has no quality-control department.

Ignatowski explains, “Although we have no quality department, we have all the quality systems in place to supply automotive—PPAP, TS certification, etc—but instead of a vertically structured quality organization, ours is embedded horizontally across all disciplines.”

QUALITY FOCUSED FROM DAY ONE

From the day it started production in 2000, it was evident that Prism was not your average shoot-and-ship custom molder. It began operations with all-electric machines, robotic parts removal, and automated packaging. That set the pattern, from the first plant in Port Huron, Mich., to the opening of the second facility in Harlingen, Tex., in 2005 and the third—now headquarters—location in Chesterfield, Mich., in 2012. All three plants operate under “white room conditions” with automated cells, plant-wide machine monitoring, and closed-loop process control. The plants look nearly identical and each is under 30,000 ft2, which Prism considers optimal for both control and flexibility. Each “focused factory” has at most eight or 10 customers so it can focus on those customers’ needs and their particular types of parts.

Each plant utilizes machine-side resin handling because central storage and conveying would present opportunities for cross-contamination, according to Ignatowski. In Chesterfield, the newest of the three plants, all utilities run under the floor. Scrap is granulated beside the press and regrind is recycled, when appropriate, in a closed loop. Prism uses SRS low-speed granulators because they produce granules that are consistently as close as possible to the original pellet size, with no longs or shorts, eliminating another source of variability. Granulators and other equipment are cleaned in a room separate from the molding area to prevent dust contamination.

All three plants use 100% electric presses and five-axis servo robots. All-electrics eliminate oil contamination and facilitate better process control, Ignatowski asserts. “We did a study a year ago on cold-runner molds and found that all- electric machines are sensitive enough that we don’t need in-cavity pressure sensors,” he notes. “We can control cushion, for example, to within 0.003 in. We control cycle times to within 0.1 sec.”

Equipment is fully standardized between the three plants: Toshiba Machine Co., America presses, Yushin America, Inc. robots, SRS granulators, Harvard Factory Automation, Inc. (HFA) conveyors, Dri-Air Industries, Inc. dryers, Conair loaders, Plastrac blenders, and Advantage Engineering, Inc. central chillers and mobile mold-temperature-control units. “We’ve standardized right down to the copier machines,” says Ignatowski, only half joking. “It removes one source of variability and it allows us to shift tools around in an emergency while making requalification simpler.

This tightly controlled pattern of development altered slightly in June 2016, when Prism purchased Tech Molded Plastics in Meadville, Pa. That acquisition at once doubled the company’s total revenues and more than doubled its employee head count and machine capacity. It also added in-house mold-building and prototyping.

“We needed the additional capacity,” says Prism co-founder, president, and CEO Rodney Bricker. The machines at Meadville include presses both larger and smaller than those already at Prism. “In addition, the acquisition brings in new customers—zero overlap with our existing base—and new market presence. There is no overlap in production, either.” Like Prism, Tech Molded Plastics made mostly automotive parts, but in this case connectors for wire harnesses and sensors. “And we gained new technology, our first in-house moldmaking capacity, and—not least of all—experienced people,” Bricker adds.

At 68,000 ft2, the Meadville plant is more than twice the size of any other Prism operation. It has mostly electric machines (Nissei America, Inc. and ARBURG, Inc.), but also some hydraulic and hybrid models. It will move gradually toward the company model of all-electric operation. Prism is investing $1 million at Meadville to add automation, warehouse capacity, and the same IQMS ERP system that ties together all the other Prism operations.

Today, with four plants, Prism has 72 presses from 33 to 440 tons, 175 employees, and sales of $60 million, which Bricker expects to grow to at least $75 million in the next couple of years. All four plants are certified to the ISO/TS 16949:2009 automotive quality standard. The company’s business is about 95% automotive: safety equipment, air/fluid systems, steering/drivetrain, connectors, and sensors. The remainder encompasses medical, packaging, and aerospace.

That business has been growing every year since the company opened its doors, says Bricker. “We thrived during the most recent downturn, both by acquiring new programs and by taking over business from other molders. In 2010 we increased capacity at Port Huron by 13% and in Harlingen by 22%.” In fact, the company has expanded capacity eight times in its 16 years of existence.

Prism doesn’t fret too much about overseas competition—it has instead benefitted from “reshoring” jobs from China and Europe. “Customers who have tried offshoring have learned that the lowest overall cost for a molding job is not the same as lowest piece price,” notes Ignatowski. “It means highest customer satisfaction with quality, delivery, and overall service. We pride ourselves on 100% on-time delivery.”

The firm also prides itself on a “lean and flat” organizational structure, aided by extensive use of automation. “We can compete globally because we don’t have excess labor cost,” Bricker asserts.

REDUCING VARIATION—EVERY STEP OF THE WAY

Prism’s campaign against variability starts with using Scientific Molding principles to run capability studies on each injection machine and checking its response to lot-to-lot resin variations. Average machine age is four to six years, not counting the newly acquired Meadville plant.

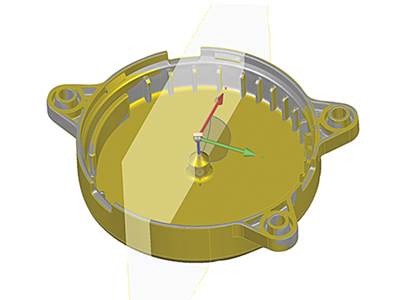

For a new molding job, flow simulation and shrinkage analysis of the mold and part are performed for Prism by Beaumont Technologies, Erie, Pa. Prism also makes use of Beaumont’s proprietary Melt Flipper technology to achieve 90% or better cavity balancing. “That allows us to run higher cavitation than our competition and maintain quality. It also helps us save material and cycle time by minimizing runner volume.” In one case, Prism took an existing eight-cavity tool design and expanded it to 16 cavities while shrinking the runner by 60% from 55.3 to 22.3 g. “That saved us 3.6¢/ part and $350,000 the first year alone—which was more than the cost of the tooling and the annual value of the program itself.”

The Meadville toolroom has the ability to build single-cavity aluminum prototype tools and high-end production-molds used in products like connectors. Meadville produces its own molds but has little excess capacity to serve the needs of the other plants.

Consequently, Prism has most of its molds built outside—by “the best in the U.S. for very tight tolerances,” claims Ignatowski—but insists on its own standards for venting, draft angles, and so on.

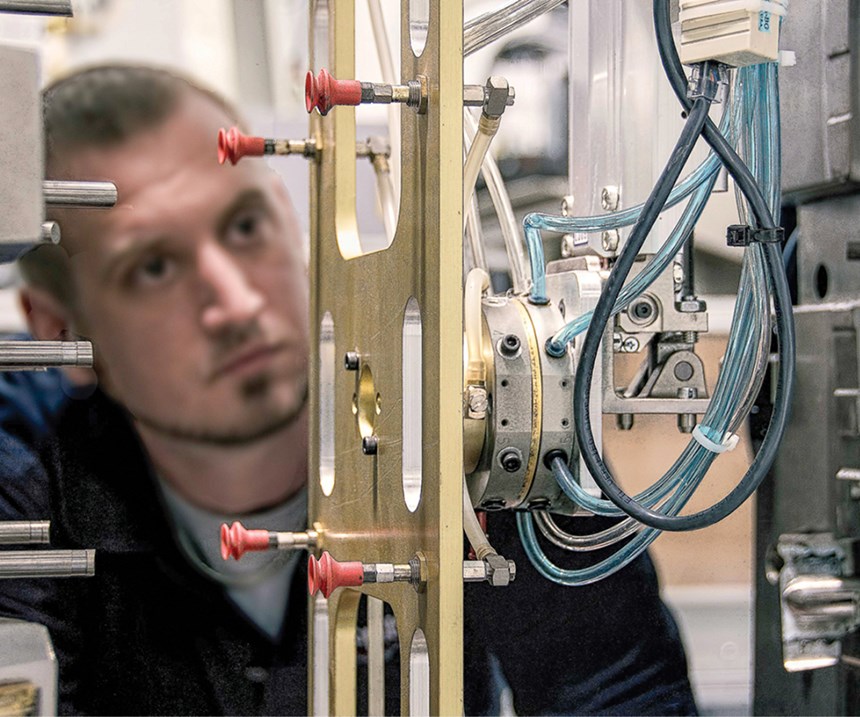

“Our tools are built like armored tanks so they can last a minimum of 1 million to 2 million shots.” Its first choice is to use hot runners with valve gates. It checks cavity balance by having the robot segregate the first and last parts to fill so they can be checked for conformity to quality specs. The Meadville plant has experience with laser sintering to 3D-print molds with built-in conformal cooling. “We expect to use that more and more,” Ignatowski says.

Once the mold is built, Prism conducts studies of gate freeze and mold balance and prepares a rheology worksheet based on the resin’s viscosity vs. shear rate curve. (Prism uses engineering resins like nylon, PPA, PPS, PEI, PET, PBT, PC/ABS, and acetal, plus some PP.) After a qualified process is determined, setup recipes for the machine and robot are recorded in a “job book.” Prism plans to move away from this hard-copy approach to storing setup data on tablets.

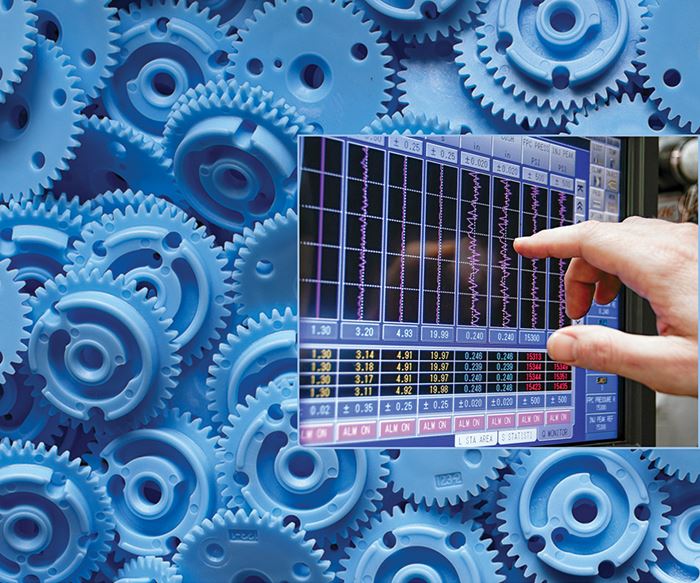

During production, process monitoring keeps a close watch on the run, with every shot subject to pass/fail qualification on the basis of 13 process variables. “The machine itself is our quality monitor,” notes Ignatowski. “We set our statistical process- control limits tighter than most people do. So nine-tenths of our in-process rejects are actually good parts.” In fact, the company claims a defect rate of less than 1 ppm.

When defects occur, Prism staff prepares a Nonconforming Report, which identifies the root cause of the problem and how to contain and correct it. “Lessons Learned” meetings are held regularly to discuss progress in reducing variability and defects.

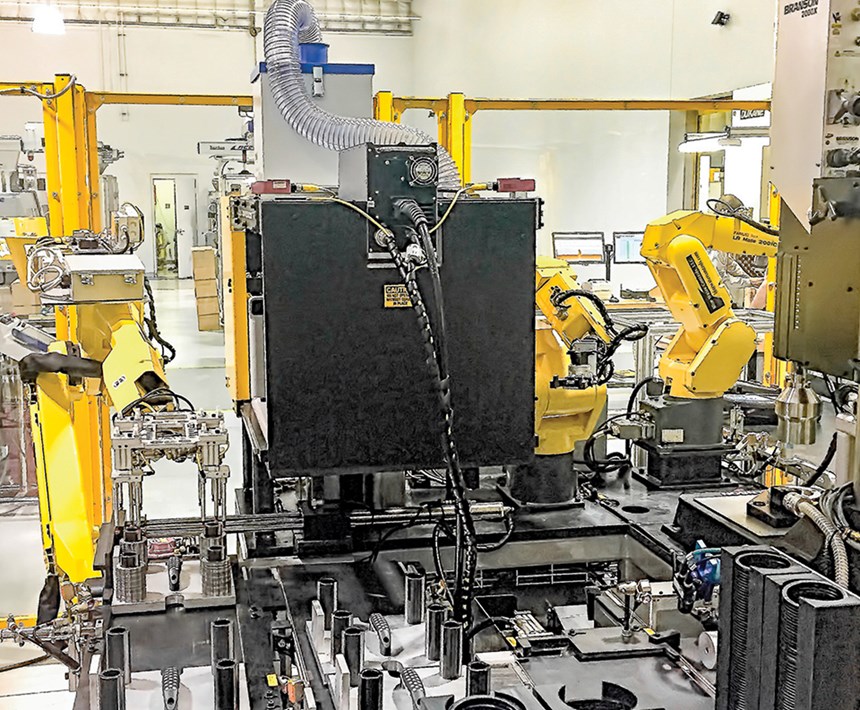

As many molders besides Prism will attest, an important factor in reducing variation is using automation wherever possible. Automation modules mounted on wheels perform operations such as degating, welding, vision quality checks, and laser etching of barcodes on parts. Prism uses robots with vision systems and vacuum sensing to confirm parts removal, cavity separation, and inline box loading or indexing carousels for box and bag filling. Box filling is controlled by weight or shot counts. A light comes on when the box is full to alert a process technician to apply tape and a label.

Prism recently installed its first six-axis articulated robot for placing metal inserts. The advantage, Ignatowski explains, is that “most molders would use a vertical press with an operator and a shuttle table for that sort of job.” Even more recently, Prism commissioned a cell with three articulated robots. The first robot removes the part from the press, laser etches a barcode, and places it in a fixture. The second robot picks it up, sonic welds it, and then hands it to another fixture. The third robot picks it up, performs vision inspection, and packages the part.

Prism is also installing its first “collaborative” robot for packing parts at Meadville— one of the new breed that can work safely alongside humans without need for guarding. It’s a “Sawyer” model from Rethink Robotics, Cambridge, Mass. (rethinkrobotics.com).

Because Prism’s plants do anywhere from 60 to 120 mold changes a month, its robots also have a quick-change system for end-of- arm tooling. “It’s a twist-and-click mechanism of our own design,” Ignatowski notes.

Another essential element of Prism’s program is its ERP system from IQMS, Paso Robles, Calif. (iqms.com). Prism relies on it for production monitoring, inventory, accounting, quoting, program management, bills of materials, shipping, and preventive-maintenance scheduling. The latter function won’t let a tool run a job if it has missed a scheduled maintenance check.

“Every piece of equipment of every cell talks to the ERP system,” says Bricker, with evident pride. He can monitor each machine and each plant on his iPad. (On the shop floor, color-coded lights display machine status: green—OK, yellow— setup, red—down or off-cycle.)

Bricker is enthused about new IQMS forecasting software that will facilitate capacity planning for the whole company to 2020. He also notes that the IQMS system gives him and other plant personnel real-time OEE statistics on each machine, which resets for each shift. OEE is Overall Equipment Effectiveness, a productivity measure that combines machine availability (uptime), performance (cycle time), and quality (defect rate). An OEE rating of 100% means the machine is making only good parts, as fast as possible, with no unplanned downtime.

“We aim to stay at 100%,” Bricker says. One of Prism’s most valuable tools for ensuring product quality is CT scanning, which literally provides “x-ray vision” of the internal features of parts, as well as highly accurate measurement (to 7-10μ on average) of exterior dimensions. “We’re using it more and more,” says Ignatowski. Due to the high cost of CT systems, Prism uses outside service bureaus.

He cites the case when Prism bid on a job to produce an automotive part with super-tight tolerances that was being molded by a competitor. “We quoted only eight cavities, even though the bobbin was already being molded in 16. We said 16 cavities weren’t feasible, and we proved it by taking CT scans of competing parts from all 16 cavities. Not a one of them was in spec.”

CT scanning also serves Prism well for reverse engineering. Ignatowski explains, “It shows where the variations from print are, so that when we build a new tool, the parts are good from the first shot.” (For more on CT scanning, see June ’15 feature) .

Related Content

50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreFakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read MoreSlimmer All-Electric Press Debuts

A slimmed-down version of Engel’s all-electric, e-mac injection molding machine is among eight displays, which also include LSR micromolding, quick mold changes and a cube mold.

Read MoreCompletely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreRead Next

CT Scanning Gives Precision Molder X-Ray Vision of Part Quality

It beats other techniques for measuring critical part dimensions, and it provides unique visibility inside parts, nondestructively. One molder’s experience illustrates the benefits.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More