Use Automated Fever Scanning to Protect your People and your Business

Sponsored ContentThis new non-contact temperature screening system from MachineSense is quick and easy to use. It provides an added level of health protection for employees and legal protection for the business.

Share

As plastics processors and mold shops open up to more workers and visitors entering their facilities, they need to take measures to keep everyone as safe as possible.During the current pandemic, fever scanning is a critical safety protocol. Still, the procedure can be awkward or error-prone when executed manually, or expensive with some of the automated body temperature scanning systems available today.

Novatec’s MachineSense has an answer for this with a new temperature scanning system called FeverWarn. Unlike infrared systems you may be familiar with that scan a person’s forehead, FeverWarn scans the back of the hand, which is a generally more reliable method. It’s non-contact, quick, accurate, and requires no human intervention. It’s also enabled for automatic data collection and can be integrated with your plant security system.

FeverSense is very fast with the capability to take a new scan in one second or less. Just place your fist under the scanner (1-4 inches away), and immediate feedback is provided via a green or red LED light or an announced voice message to proceed or await further instruction. The results of the measurement can be stored locally or in the cloud for archival and reporting purposes, which reduces legal risk. Measurement results can also be transmitted to a mobile app with immediate alerts sent whenever an elevated temperature is detected. The device is FDA compliant and accurate to ±0.9 degree F.

Why You Need to Screen

A fever is the most common coronavirus symptom, affecting up to 88 percent of those who have the ailment. This telling symptom can be easily monitored with FeverWarn by conducting temperature screenings to alert potentially sick employees or visitors and keep them from exposing others. Taking this measure can be important to employees. Knowing they are coming to work in an environment that is as safe as possible takes away stress. It builds confidence, allowing employees to perform their jobs in safer surroundings without undue health-concern distractions.

Then there is the legal issue to consider. The Centers for Disease Control and Prevention (CDC) has recommended that businesses not only protect their employees but also monitor employee health regularly. Legal experts assert that companies that fail to maintain minimum standards, including health monitoring and screening, could be subject to liability or workman’s compensation issues if employees, visitors, or customers claim they contracted the virus at such a facility.

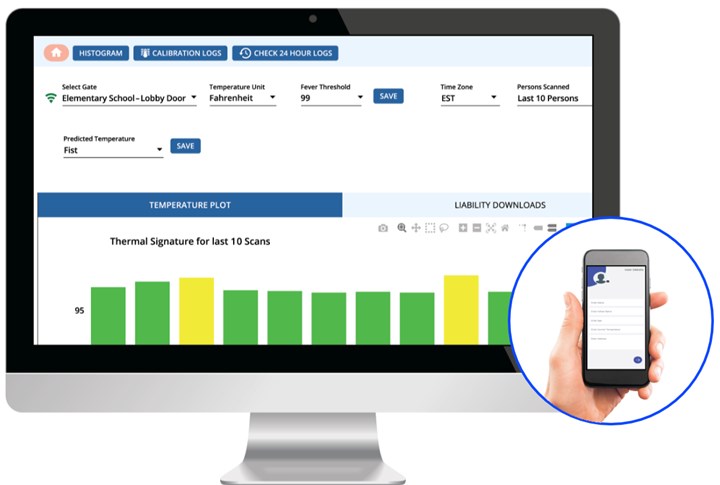

FeverWarn software reduces legal risk through the ability to store scan data, calibration logs, and data from visitor waiver forms. Data can be stored locally at the plant or uploaded to cloud storage, depending on the FeverWarn model selected.

Disease compliance data backups and full reporting are an important part of avoiding these future claims, which is why IoT enablement of a scanning device is so important. Most handheld devices and even many thermal capture systems have no way of retaining data and generating visual reporting. FeverWarn’s software automatically stores complete scanning data locally or in the cloud.

The Science of Fist-Forward Temperature Scanning

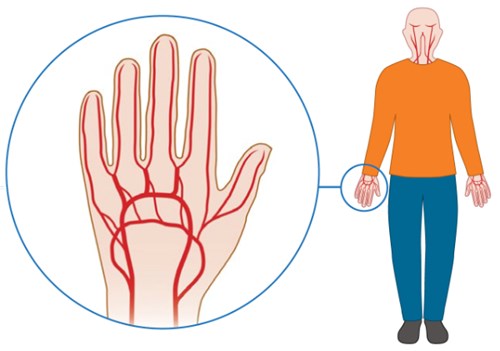

While skin body temperature and core body temperature will differ by one to two degrees, they nonetheless correlate well to detect fevers. Many noted university studies have established that although different skin temperatures (hands, legs, feet, stomach, chest, and forehead) may not be the same, they still correlate well with mean body temperature (MBT), which is used to measure fever. These same studies have shown that the fist/wrist area is one of the most reliable and steady thermal scan areas because it is less affected by thermal activity.

Thermal scanners work best in high blood flow areas, such as the back of the hand. Hand scans are generally more reliable than forehead scans because they are less obstructed by heavy perspiration, hair, makeup and other facial coverings.

There are also several very practical reasons why fist/wrist scanning is more reliable. Many people are familiar with infrared (IR) skin temperature devices being used to monitor forehead skin temperature. But due to factors such as heavy perspiration of the forehead area, hair, makeup, and other facial coverings, the readings can be compromised and often require secondary scans. In fact, thermal scans can be taken in many places on the human body, especially those regions where arterial blood flow is present. Still, some areas, including the fist, are better suited to correlate with mean body temperature (MBT). Another reason the fist/wrist area is an optimal temperature scanning area is because people can easily manipulate their arm/hand and scan themselves. In contrast, people of different heights would require multiple scanners to achieve the same results with a forehead scanner.

Thermal scanning camera systems are also available on the market. But they are expensive, and a high-resolution camera is necessary to direct the image to the correct facial areas. Also, infrared cameras cannot be used outdoors due to the interference of the sunlight’s ultraviolet rays which will impact the results.

Easy Installation

FeverWarn on optional stand.

All standard components of a FeverWarn system are shipped in a single box which includes:

- Sensor/Scanner unit with embedded data hub

- Dual power USB adapter

- All cabling

- Speaker (for audio enabled models)

Access to the mobile app is also included as well as one year of free access to the cloud-based software. For installation, you just mount the sensor/scanner unit to a wall or an optional stand, connect the cables, plug in the power adaptor, and connect the unit to your plant router.

Establishing a reliable and systematic protocol for fever scanning can’t get much easier than this. Plant managers should consider installing this vital safety measure as if their people’s and their businesses’ lives depend on it.

Click here for more information on FeverWarn or download the brochure now.

.png)