Paxis, Sartomer to Develop Custom Materials for Additive Manufacturing

Sartomer will work with Paxis to develop a library of new custom materials tailored to work with the Wave Applied Voxel (WAV) technology and solve application-specific needs.

Paxis and Sartomer will develop custom materials for additive manufacturing.

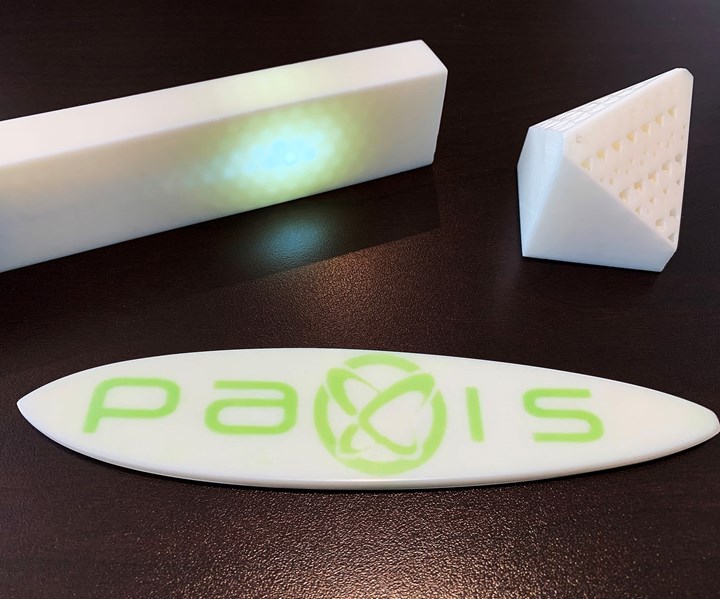

Sartomer, part of the Arkema group, and Paxis, a 3D printing provider, are co-developing custom materials for Paxis’ WAV (Wave Applied Voxel) additive manufacturing process technology.

The WAV process is a new, scalable industrial additive manufacturing process designed to solve the limitations of existing liquid-resin-based technologies. The patented WAV technology reportedly enables scalability in size and speed and a significant reduction in post-processing requirements. It also features multiple material production, the elimination of a large vat during large-part production and the ability for embedded components.

Sartomer will work with Paxis to develop a library of new custom materials tailored to work with the WAV technology and solve application-specific needs. Paxis and Sartomer also look to identify new market opportunities. The UV-curable liquid resins in Sartomer’s N3XTDIMENSION product portfolio are specifically designed to promote high-performance and tailored characteristics of 3D-printed products.

“Sartomer is a historic partner for 3D printing innovators, and we are excited to collaborate with Paxis because WAV technology is positioned to change manufacturing as it exists today,” said Sumeet Jain, senior director, 3D printing worldwide at Arkema. “Through our joint efforts, we aim to develop next-generation products and solutions that will continue to disrupt and advance the way parts are mass manufactured.”

Related Content

-

At DI Labs, Mass Customization Is a Necessary Step on the Way to Additive Manufacturing’s Production Future

The Minnesota company is applying lessons learned from its custom automotive aftermarket business, Threedom, to advance processes and workflows for AM at scale.

-

3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

-

5 Trends in 3D Printed Injection Mold Tooling

3D printing has moved beyond conformal cooling, and is now being applied to injection molds more broadly. Observations on additively manufactured mold tooling from the Plastics Technology Expo — PTXPO 2025.