Automation: Digital Twin Allows Slow-Motion “Replays” of Robot Movements

Wittmann Battenfeld say all data are recorded in the R9 control’s video assistance system within 4 msec and can be traced back into the past for up to 100 seconds, letting molders replay incidents.

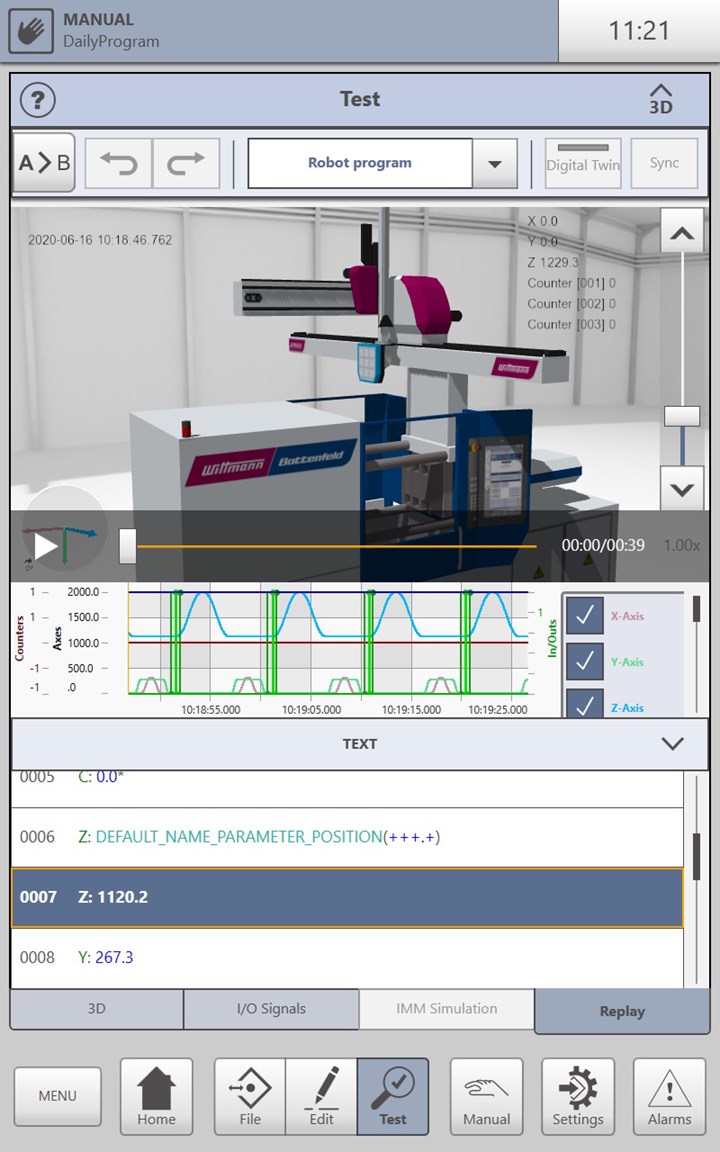

Injection molding machine, automation and auxiliary supplier Wittmann Battenfeld (U.S. headquarters in Torrington, Conn.) says all its robots with R9 control systems now support a video assistant that is manage by a digital twin or electronic version of the physical robot. Displayed directly on the TeachBox, the digital twin can replay preceding sequences at any desired speed. Since it has access to the configuration of the physical robot on which it is installed, the digital twin is familiar with that robot’s equipment options and is able to visualize these accurately.

Once the physical robot switches into the automatic operation mode, the twin records all changes in the positions of the individual axes, including the entrance/exit points, the counters and all other values relevant for the robot’s operation. All data are recorded with accuracy to 4 msec, and they can be traced back into the past for up to 100 seconds. Each executed teach command is also saved.

A practical example of a potential application for this capability would be investigation of a robot undergoing an unplanned standstill. When the standstill occurs, the data recording stops and the preceding 100 seconds are available for analysis. The TeachBox’s time controller allows the user to define a point in time within the displayed sequence. This controller can be shifted in both directions as desired, in order to examine in detail any status changes that occurred.

During the analysis, the physical robot could maintain operation since only the digital twin is moved on the TeachBox, and only its status changes are displayed. That way, Wittmann Battenfeld says the video assistant makes it easier to detect causes of defects, while supporting the operator’s efforts to prevent a repetition of similar incidents.

Wittmann Battenfeld’s R9 control for robots features a digital twin that allows molders to “replay” robot movements.

Related Content

-

Automation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

-

50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

-

Ensuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.