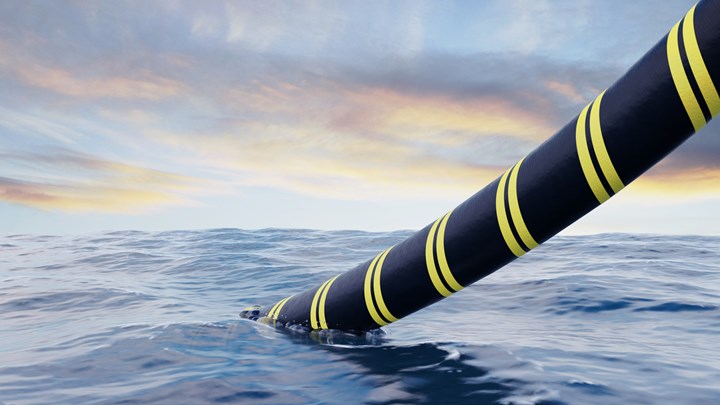

Conductive Carbon Black for Wire & Cable Applications

Orion’s new carbon black reportedly enables compounders to attain target conductivities at low carbon black concentrations, and it allows converters to realize an excellent balance of conductivity and mechanical properties

A new carbon black specifically designed for semi-conductive compounds in medium voltage cable has been developed by global supplier of specialty and high-performance carbon black Orion Engineered Carbons S.A. This carbon black is said to be suitable for the conductor shield or insulation shield, depending on the specific voltage and application, while the company’s previously launched Printex kappa 70 is suitable for the conductor shield.

Said Sandra Niewiem, senior v.p, global specialty carbon black and EMEA region at Orion, “To qualify for wire and cable insulation and strand shield applications, carbon black must disperse readily in polyethylene and various elastomers, show very low levels of ionic contamination, and impart target conductivity to minimize dielectric stress between the conductor and cable insulation. Our new wire and cable carbon black and Printex kappa 70 beads have met these requirements, and we are sampling both grades among cable makers and compounders.”

In injection-molded parts, the universally conductive Printex kappa 70 beads are specifically geared for compounds and end uses requiring conductivity and anti-static properties. They excel in almost all conductive processes and products. They are suitable in PP, PC and its alloys, a broad range of engineering thermoplastics, as well as styrenics and PVC. They boast excellent dispersion quality, compound melt flow and mechanical strength. The new conductive black reportedly enables compounders to attain target conductivities at low carbon black concentrations, and it allows converters to realize an excellent balance of conductivity and mechanical properties for their applications.

Orion has a long-term sustainability strategy based on three key trends, one of which is electrification. In keeping with this strategy, the company welcomes the opportunity to provide carbon black for additional shielding applications in the country’s growing fleet of electric cars. The other key trends are decarbonization (reducing carbon dioxide emissions) and circularity. Responding to these trends, Orion is committed to sustainable growth with a minimal environmental footprint. The company expects to shift its product portfolio toward carbon black made from renewable materials or oil derived from end-of-life tires. Orion is also focusing on carbon black, such as conductive black, that supports the transition to a low carbon economy.

Related Content

-

Resins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

-

BASF to Purchase Pyrolysis Oil Produced From Waste Plastics

Agreement with Arcus Greencycling GMBH anticipates a volume of 100,000 ton/yr.

-

Graphene-Enhanced Stretch Film Billed as 'World First'

Thinner, stronger films to be commercialized by Brazil’s Packseven in August.