Inline Inspection System for Wood Plastic Composites

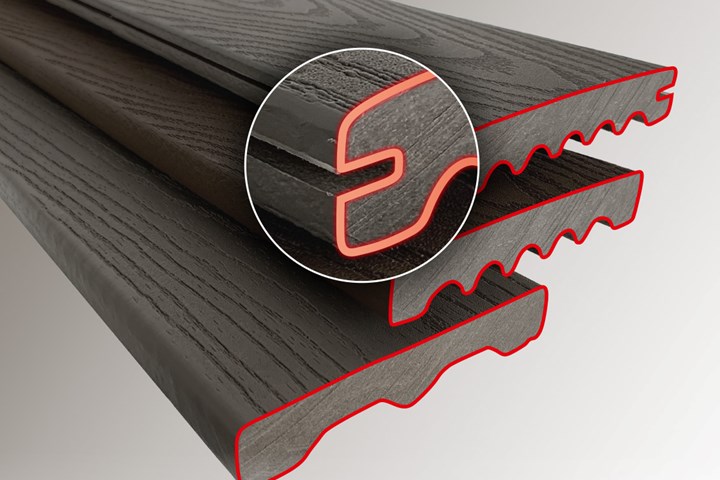

Pixargus’ ProfilControl 7 DX WoodPlasticComposites measure all dimensions and geometrics, including deep grooves.

A new inline inspection system from Germany’s Pixargus (U.S. office in Chester Township, Ohio) has been designed to ensure that all wood plastic composite (WPC) deck boards leaving a manufacturing line are of perfect shape. ProfilControl 7 DX WoodPlasticComposites system boasts a compact design and is based on Pixargus’ proven and successful PC7 inspection technology for geometry measurement of continuously extruded long products and single, cut-to-length pieces.

Pixargus adapted its best-selling system for the challenging task of WPC and NFC (natural fiber composite) inspection. In addition to the profile geometry, the system is particularly suitable for the 100% measurement of critical features, such as deep grooves. As such, processors can be sure the grooved edges of their deck boards are fully automatically inspected, guaranteeing that they will fit perfectly in a decking construction.

High-precision optics and sophisticated algorithms reportedly allow ProfilControl 7 DX to handle profile geometries of any kind and complexity. The systems measure features such as distances, angles, radii and combinations thereof through 360° of the product in real time. However small, any deviations is instantly indicated, from the reference profile, allowing the production process to be optimally controlled at all times.

Related Content

-

Measuring Technology Specialist Pixargus Acquired by CiTex Group

A global player in optical inline quality control, Pixargus is intensifying presence in U.S. & Asia under CiTex umbrella.

-

How to Improve Quality with Offline Inspection and Analysis

Automated sample testing with a light table detects the smallest contamination in flakes, micro granulates and sample test sheets.

-

Robust Rotational Viscometer

Versatile viscometer line said to offer robust measurement, repeatability and reporting.

.png;maxWidth=300;quality=90)