Sustainable Materials is Focus of Thermoforming Exhibits at K 2022

Thermoforming equipment makers including WM, Kiefel, and OMV will showcase processing of recyclable and biobased materials.

Key thermoforming equipment manufacturers exhibiting at the upcoming K 2022 trade shown in Dusseldorf, will focus on the use of sustainable materials for thermoforming as well as upgraded machines. Included are:

▪ WM Thermoforming: The company will present performance improvements on their machines such as the new version of their flagship thermoforming machines, the FC 780E. It reportedly allows for better mold adaptability, said to save processors significant investments in mold changes. The new version also features noteworthy improvements in software such as easier human-machine interaction, rationalization, and aesthetics.

Also presented will be a patent-pending, new and improved stacking system that will reportedly “shake up the performance on tilting machines,” according to WM general manager Luca Olivierio. Moreover, the company plans to explore themes related to new materials and will present results of the production tests they have been conducting on new foam materials and new barrier monomaterials—the result of test molds created in collaboration with WM Thermoforming’s strategic partners.

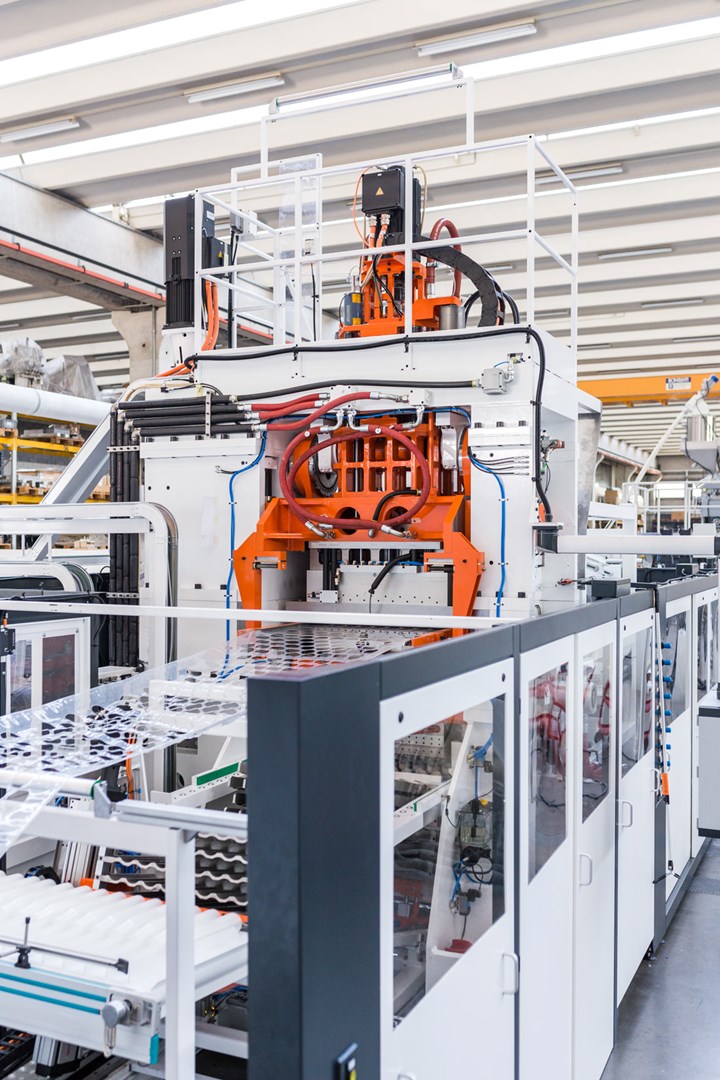

▪ Kiefel, Div. of Brückner Group: The company will be presenting machine, tool, and automation solutions for processing recyclable and biobased materials. In live demonstrations with the KMD 78.2 Speed steel rule tilting machine, the company will illustrate how high-quality sustainable packaging products are made from recycled film, making a contribution to tray-to-tray recycling. This is made possible by in-house, unique tool technology and smart automation concepts. Kiefel is unveiling the new Kiefel Speed Automation (KSA) at K 2022.

Kiefel will also present the latest advances on its packaging technology from fiber thermoforming of natural fibers, now in high demand worldwide. Large numbers of the Natureformer KFT 90 machine, which deploys this technology, are already operational worldwide. The KFT Lab laboratory machine will be used to illustrate the production process and suitable food and non-food applications for the technology.

Innovations for the medical and pharmaceutical industry will also be highlighted as Kiefel will exhibit its expanded portfolio of bioprocess bags with the requisite machine technology. The 3D and 2D bags can be made from PVC-free materials such as PE or PP, or from PVC or EVA. Depending on the customer's requirements, a wide range of options can be implemented. These include semi-automatic or fully automatic machines, disposable bags for the storage of stem cells, cell cultures, mixing or separation, in 2D or 3D designs or hose/port connection components.

▪ OMV Technologies will be showcasing the latest in its turnkey extrusion and thermoforming technology including the RM77 with in-line rim rolling technology that is capable of 55 cycles/min, and with the right tool, can produce over 4000 parts/min. The new OMV has a renewed emphasis on groundbreaking technology, sustainability, and customer service, with all the changes in leadership, management, market focus and headquarters. In late 2021, OMV Machinery S.R.L. (Verona, Italy), a division of Swiss-based Wifag/Polytype Holding AG, was purchased by Florida-based MalStra LLC (Royal Palm Beach, Fl.).

OMV has worked closely with its customers throughout the design development stage to reduce the amount of plastic in containers by up to 30%. The company has forged partnerships with processors and brand owners to incorporate up to 100% post-consumer recycled (PCR). OMV’s unique processing technology reportedly allows for incorporation of up to 100% PCR flake with no tradeoffs in purity, while meeting all of the necessary functional demands and industrial food-grade requirements.

Among its efforts to drive sustainable packaging, OMV is working with leading brand owners in the U.S. to develop single-source, mono-material solutions as a replacement for multilayer structures. In a unique thermoformed meat tray application with a leading processor, the tray and film seal are the same material. OMV will highlight such disruptive technologies which deliver strong barrier properties and a more sustainable and environmentally-sound packaging option.

.Related Content

NOVA’s BOPE-HD Film Resin Gains in Globally Available Flexible Food Packaging Applications

Positioned as a recyclable packaging alternative to traditional BOPET films, BOPE-HD film is now available from companies such as Inteplast, JK Materials, Oben Group, and Polivouga.

Read MoreMetaspectral to Advance Vision Technology for Recycling

Company received further funding from British Columbia’s CleanBC Plastics Action Fund

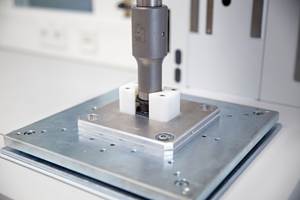

Read MoreCan Plastic Recyclates be Welded Ultrasonically?

What is possible with ultrasound? Will the result with recycled plastics material actually be worse than with standard material? Do we have to adapt our technology?

Read MoreS&B Selected as Contractor for New Hope Energy Advanced Plastics Recycling Unit

New Hope Energy and Total Energies collaboration for an advanced plastics recycling unit gains momentum.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More