Tooling: Combined K 2019 Booth for Hot Runner, Molds and Process Control Brands

Barnes Group will collocate its Molding Solutions strategic business unit in a combined booth for the first time at K 2019, with FOBOHA, Gammaflux, männer, Priamus, Synventive and Thermoplay sharing a stand.

The company said dispalys will focus on specific customer applications in markets ranging from medical/pharmaceutical, personal care, packaging, automotive and technical parts markets, as well as electrical and household applications.

Cube Technologies on Display

FOBOHA will present two cube technologies at the 2019 “K” trade show: Plug ‘n Play Compactcube, which the company says provides rapid installation and easy maintenance, and the Reversecube, which FOBOHA describes as a system of counter-rotating cubes that can replace multiple molding machines and automated assembly units with a single system. At K, the Reversecube will run on an Arburg injection molding machine. Tying into the broader theme of a circular economy and sustainability at K, Barnes Group said its stand will highlight its work with biologically produced, biodegradable and post-consumer recycled plastic (PCR).

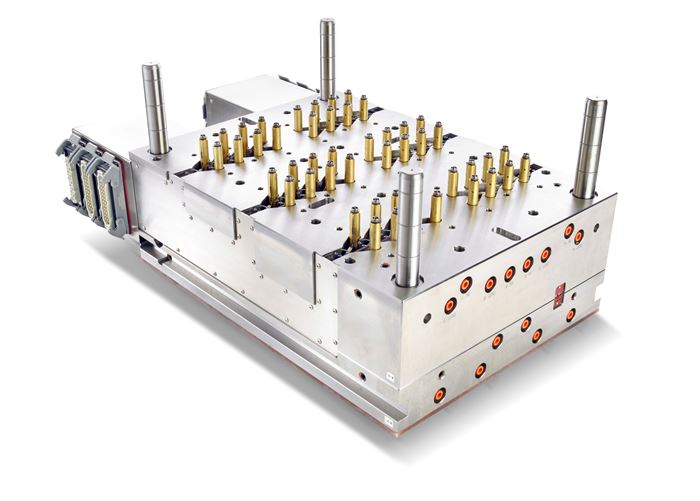

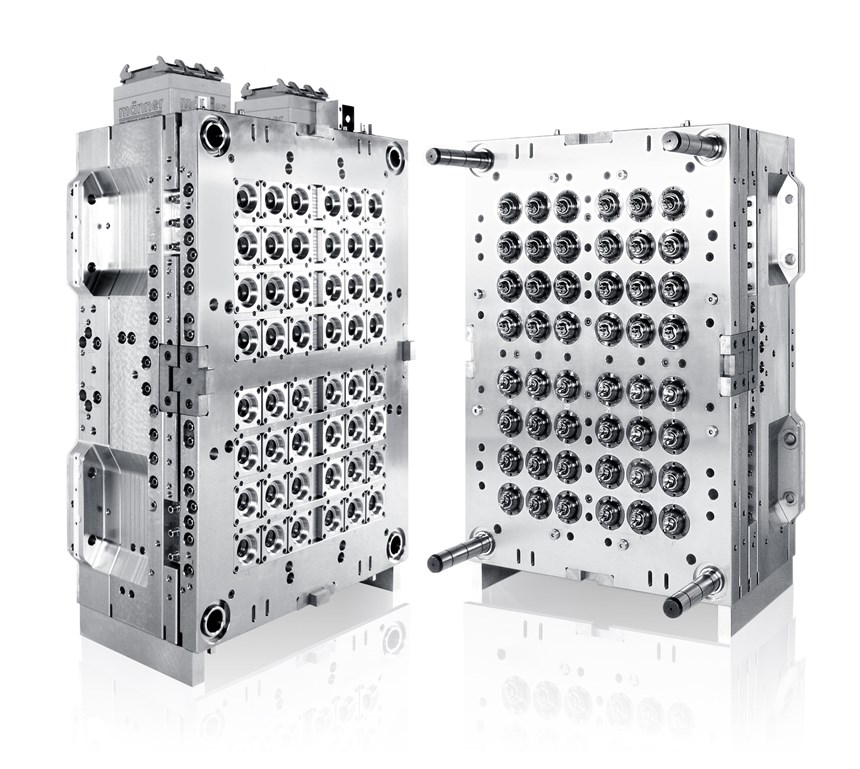

Valve Gate Hot Runners in Control

männer will use K 2019 to promote its patented Cylindrical Valve Gate, and Thermoplay will present its new range of hot runner systems for multicavity molds up to 144 cavities. Barnes notes that within its Molding Solutions business unit, männer, FOBOHA, and Thermoplay represent the multicavity tool and hot runner capabilities within the company, serving the market for medium- and high-cavity applications.

Synventive, Barnes notes, primarily serves the automotive, industrial, electronics and household goods industries with larger output lower-cavity solutions. For the first time at a European show, Synventive will present its new generation eGate system. The servo-driven valve gate is now available for larger components, promising complete pin movement control on each individual nozzle. At the show, there will be a live demonstration of the SynFlow two-speed pin control technology. SynFlow for hydraulic cascade molding reportedly offers more melt flow control and has a new controller.

Process and Temperature Control Promoted

Priamus will present its Quality Monitor technology, saying the technology can help with process control for molders running biopolymers and recycled materials; these materials can exhibit more fluctuation in material viscosity, impacting process stability. Priamus notes that Quality Monitor also features an OPC-UA control architecture in support of Industry 4.0.

Gammaflux will present several upgrades to its G24 temperature controller, including an integrated hydraulic power unit (HPU). This HPU can be used to control hydraulic valve gate systems with an integrated cascade control (SVGC). The second system integrates the männer e-control (servo control) into the G24. In addition, together with Priamus, Gammaflux has also integrated the Quality Monitor quality assurance monitoring software into the G24.

Related Content

-

New Designs for Electric & Hybrid Packaging and Industrial Blow Molding Machines

Introduced at K 2022, Bekum’s 21 models in the new EBLOW 8 Series and XBLOW designs include all-electric packaging machines from small to large, plus industrial units with a novel two-stage clamp in servohydraulic or hybrid versions.

-

Breaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

-

New Technology Bonds Aluminum With Polyamides

With many benefits for numerous potential applications, including in the burgeoning electric vehicle market, Celanese’s Zytel Bonding Technology achieves stronger bonds than overmolding or welding.

.png;maxWidth=300;quality=90)