Materials

Teknor Apex and UBQ Materials to Further Expand Development of Sustainable Materials

Their strengthened compounding partnership will expedite product development.

Read MoreRiverdale Global Showing Latest Innovations and New Satellite Location in Wisconsin

NPE 2024: Live demos of updated RGS controller are among the highlights at its Wisconsin facility that will house the ‘new’ color R&D lab.

Read MoreUse Purging Compounds to Mitigate Processing Challenges of PCR and PIR

With frequent purging, you can minimize serious contamination issues and get both better results and higher profits.

Read MorePrices for PE, PS, PVC, PET Trending Flat; PP to Drop

Despite price increase nominations going into second quarter, it appeared there was potential for generally flat pricing with the exception of a major downward correction for PP.

Read MoreLaser Marking Additives for Diverse Plastics

NPE 2024: Tosaf launches additives that boast exceptional transparency.

Read MoreSyntactic Foam With High Service Temperature and High Friction for Thermoforming

NPE 2024: CMT Materials showcases new plug-assists Hytac HTF copolymer syntactic foam.

Read MorePIR/PCR Recycled Content and Biobased TPEs for Broad Range of Applications

NPE2024: Kraiburg TPE launching PCR/PIR content polyolefin-based TPEs and its expanded line of Thermolast R biobased TPEs.

Read More'Dual Action' Purging Compound Accelerates Color Changes

Shuman Plastics’ Dyna-Purge Division launches Dyna-Purge L, extending its “3X technology.”

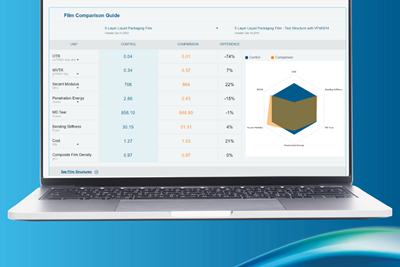

Read MoreUpdated Interactive Tool for Predicting Multilayer Film Performance

NPE 2024: NOVA Chemicals presents the latest enhancements to its Bonfire Multilayer Property Predictor and new Syndigo rPE portfolio

Read MoreLong-Chain Nylons for Wide Range of Processes

NPE 2024: NYCOA is now offering NXTamid T Nylon 610 and 612 grades as part of its transformation into a specialty nylon company.

Read More