Stretch Blow Molding

Latest Stretch Blow Molding Articles

VIEW ALLICYMI: September Roundup

The FYI on MDO, turbulence as a good thing and gearing up for a new future at Winzeler Gear all feature in the top articles from September that you might have missed.

Read MoreK 2025: New Hybrid ISBM Machine Offers Upgrades for HDPE Bottles

Nissei ASB introduces hybrid version of ASB 70DPH machine that offers greater productivity and design freedom for HDPE bottles.

Read MorePET Bottle Design Combines Super Light Weight With Premium Aesthetics

KHS adopts a “premium lightweight approach” with its new 0.25-L KHS Premium Lite PET bottle for still water.

Read MoreSidel Launches ‘Game-Changing’ Laser Heating for PET Preforms

“World’s-first” technology promises higher quality and productivity, lightweighting and lower maintenance.

Read MoreBlow Molder Packs Sustainability Into Every Container

With back-to-back EcoVadis platinum recognitions, Ring Container Technologies is a sustainability frontrunner. PT toured the company’s Fontana, California, blow molding facility to see what it takes to be an eco-conscious producer of plastics packaging.

Read MoreAI Upgrades Closure Inspector for Tethered Caps

KHS has enhanced its Innocheck TSI closure inspector with AI capabilities for tethered caps on PET bottles.

Read MoreLatest Stretch Blow Molding News And Updates

Recyclability of PET/PEF Multilayer Barrier Bottles Gets Further Validation

Europe’s RecyClass considers PET/PEF multilayer bottles to be fully recyclable in the PET stream.

Read MoreCobot Automates Label Reel Loading for High-Volume PET Beverage Bottles

Sidel’s new CoboREEL system uses a cobot to automate a shift’s worth of label reel loading.

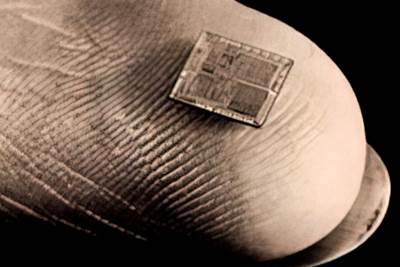

Read MoreUltralight PET Preform Design

The Factor 101 design created by KHS and Husky uses just 5.89 g of material to hold 591 mL of product — equivalent to a 20-ounce water bottle.

Read MorePrecision Concepts Buys Meredith-Springfield

Latest acquisition by this diversified producer of rigid packaging is a Northeast leader in technical blow molding.

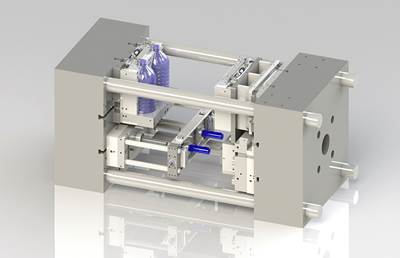

Read MoreMake PET Containers From 20 ml to 5 L on One Machine

Cypet’s new PRO Series of one-stage injection stretch-blow molding (ISBM) machines boasts high flexibility, high output, fast payback.

Read MoreLightweight Bottle Base for 100% rPET Still Products in High-Speed Production

Sidel’s new StarLITE-R Still base design for still products meets the combined challenges of lightweighting, high-speed production and 100% rPET.

Read MoreFeatured Posts

Is There a Better Way to Heat PET Preforms for Stretch-Blow Molding?

Is near-infrared (NIR) heating better, faster and more energy efficient? So far, only two machine builders are making such claims for NIR in place of standard mid-infrared preform heating, though their systems appear to be well accepted. Meanwhile, an altogether different alternative is in the works.

Read MoreFor Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

Read MoreBreaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

Read MoreAt NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read MoreHow Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

Read More50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read More