Motan, Inc.

320 N Acorn St.

Plainwell, MI 49080 US

800-991-9921 | 269-685-1050

motan.com

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

Motan, Inc. Supplies the Following Products

- Blenders (non-intensive)

- Closed-loop Process Control Systems

- Conveying Equipment (pneumatic and Mechanical)

- Dewpoint Monitors/Moisture Analyzers

- Dryers for Resins

- Dust Removal Equipment

- Feeders

- Hopper Loaders

- Hoppers, Bins, Tanks

- Level Sensors and Controls

- Metal Detectors, Separators

- Metering, Proportioning Equipment

- Pressure Controllers, Monitors

- Semi-bulk Containers

- Silos

- Valves, Gates, Diverters

- Weigh Scales

Editorial, News, and Products

-

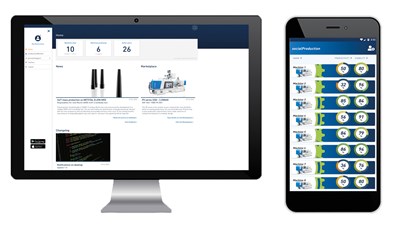

Connectivity for Material Handling Offers Greater Visibility

NPE2024: Motan solutions integrate data connectivity.

-

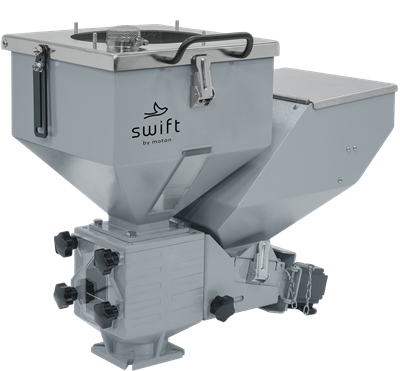

Volumetric Unit Offers Consistent, Accurate Masterbatch Dosing

NPE2024: Compact feeder mounts directly to the feedthroat of the primary processing machine.

-

'Simple' Units Feature State-of-the-Art Controls

NPE2024: New dryer line from Motan billed as the most cost-effective entry-level models it offers and comes equipped with state-of-the-art control technology.

-

Loaders, Blenders Made Specifically for Medical Processors

NPE2024: FDA-compliant auxiliaries suited for injection, extrusion, blow molding.

-

Application Records, Displays all Sustainability Relevant Process Data

KraussMaffei (KM) says new software provides in-depth process data by capturing up to 500 machine signals in real time for carbon footprint measurement.

-

Conveying: Compact Unit for Smaller Systems

New line said to be an optimal and inexpensive solution for lower-volume applications.

-

K 2019 Report: Auxiliaries Stake Their Claim in the Circular Economy

The theme of sustainable plastics pervaded the exhibits at K 2019, even those of auxiliary equipment suppliers, where everything from dryers to blenders to hopper loaders was reimagined as part of a circular plastics process.

-

K 2019 Preview: Auxiliaries Showcase Connectivity & Efficiency

At press time, a handful of auxiliary suppliers shared some of their K 2019 plans, highlighting connectivity and efficiency in their planned displays.

-

Who’s Doing Research to Advance the Plastics Industry?

Machinery suppliers are taking the lead in plastics R&D. Engel offers one example.

-

Giving the ‘Royal’ Treatment in PET Packaging

In the U.S. for just seven years, Royal Interpack is emerging as a growing, innovative, customer-centric supplier of food packaging.

-

NPE2018 New Technology Focus: Resin Conveying

From RFID couplings to 'Wave' conveying, material is moving smarter at NPE.

-

Auxiliaries at NPE2018: Packing More Functions in Less Space

Auxiliary equipment suppliers are building more and more technology into their products, packing more physical and virtual functions into the same or smaller footprints.

-

Coupling System Has RFID Option for Error-Free Connections

Coupling system for pneumatic conveying lines is available in either uncoded or coded versions.

-

Mobile Dry-Air Dryers for Small Throughputs Feature Integrated Conveying

By entering the material to be dried, the system automatically fills the drying bin and applies resin specific pre-drying conditions.

-

Augmented Auxiliaries At K 2016

Incremental improvements to existing technologies combined with altogether new advances at the giant show.

-

Highlights of Fakuma 2015

A selection of the hottest news and molding trends at this “little brother” to the K Show.

-

'Talking’ Machines Pave the Way for Processing Plants of Tomorrow

At the convergence of smarter equipment, open communication protocols, and more powerful networks, a new shop floor emerges where groups of intelligent machines work seamlessly as integrated systems.

-

Global Processors Establishing U.S. Footprint

Two major international processors establish plants in central Pennsylvania to serve the U.S. market.

-

AUXILIARIES AT NPE: More Control, Flexibility, And Efficiency

These are key trends in the many kinds of auxiliary equipment displayed at this month’s show. You’ll also see equipment designed to be virtually ‘foolproof.’

-

Resin Conveying: No More ‘Spaghetti Bowl’

You now have technology choices to avoid the maze of conveying tubes that form a ‘spaghetti bowl’ or ‘rat’s nest’ in a central materials-handling system. Here’s how they stack up.

-

K 2013: More Efficient, Flexible & User-Friendly Auxiliaries

It’s hard to generalize about auxiliary equipment, but a few trends stood out at K, including: greater energy efficiency, ease of maintenance and cleaning, controls that provide more real-time and historical process information and greater ease of use.

-

Auxiliaries at NPE: New Solutions from Material Preparation To Post-Mold Operations

There will be an extraordinary range of new auxiliary equipment on display at the show.

-

News in Auxiliaries & Tooling at Fakuma Show

Late last month, Friedrichshafen, Germany, hosted Fakuma 2011, the largest European plastics show of the year, growing to be second in size and importance to the K show in Dusseldorf.

-

New U.S. Molding Operation Brings Processing In-House

Freudenberg Household Products (FHP), Germany, known in the U.S. for its line of O-Cedar mops, brooms, dust pans, etc., has joined forces with Spanish injection molder SP Berner Plastic Group, S.L., to form a joint venture company called FHP Berner U.S.

-

NPE News Wrap-up: Resin Dryers

At least 16 companies introduced new dryers at the big show in Chicago. The new models span a range of drying technologies, but most sport features that save space and cost and make the dryers simpler and more reliable.

-

Materials Handling: New Equipment Emphasizes Efficiency & Value

Visitors to the recent NPE 2009 show in Chicago were looking for materials handling equipment that could do more than dry, blend, or convey resins. It had to do those things while saving energy, providing faster and easier maintenance, speeding product changeovers, reducing labor cost, minimizing waste, and providing better value for money. The new products cited below addressed those needs and more.

-

NPE 2009 News Flash

Injection MoldingHybrid Press Has Electric ClampNew injection presses that combine servo-electric and hydraulic movements to achieve high performance with energy efficiency will be discussed by Arburg Inc., Newington, Conn.

-

HOW TO COMPARE DRYERS? A Complex Challenge With No Simple Answers

Is one type of resin dryer faster or more energy-efficient than another? That question prompts competing claims from suppliers—but very little concrete data. When one vendor performed controlled tests to get some answers, its results, published here for the first time, prompted further debate about the difficulties of making valid comparisons and the many complex issues involved in dryer selection.

-

NPE 2006 News Wrap-Up: Fluid Temperature Control: Saving on Energy and Maintenance

At NPE in Chicago, chillers and TCUs were put on a lean energy diet and redesigned for greater durability. Suppliers also added features while taking out cost.

-

NPE 2006 News Wrap-Up: Materials Handling: A Host of Refinements and Updates

NPE 2006 held no revolutionary changes in dryers, blenders, feeders, loaders, or conveying controls, but widely adopted improvements make the newest models easier to use and maintain—and easier on the budget, too.

-

What to See at NPE 2006: Heating and Cooling

Most of the news at the show is in fluid-circulating mold-temperature-control systems.

-

What to See at NPE 2006: Materials and Parts Handling

Dryers, feeders, blenders, loaders, metal detectors, level sensors, mechanical and pneumatic conveyors, silos, bins, pumps, filters, valves, box fillers, bag dumpers, and materials-handling control systems constitute one of the biggest categories of products on display at NPE.

-

Resin Dryers: Which Type Is Right for You?

Processors today face bewildering choices of at least five basic types of dryers, whose capabilities are subject to conflicting claims from equipment suppliers. For the buyer, the most basic questions are: How much drying is needed for the job and which dryer types are up to the task?

-

NPE News Wrap-Up: Materials Handling

The big show in Chicago presented more new loaders, feeders, blenders, and conveying controls than you could count. They’re more flexible, easier to maintain, and easier to control. Many are web-enabled, and some are lower in cost.