Bidding So Long — But Not Goodbye — To Plastics Icon Matt Naitove

After 51 years of contributing content, plastics industry stalwart will take a step back.

Many times, this page is the last piece of content produced for the publication. When you’ve written as many of these editorials as I have, it can be a struggle to come up with a topic worth reading, month and in and out, year in and out. I had no such challenge this time.

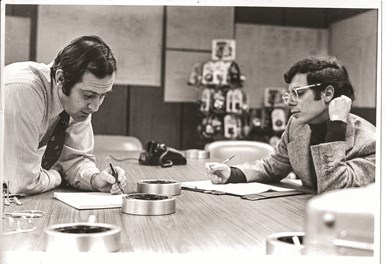

Matt Naitove (right) in 1972

Matthew Naitove has been a part of the Plastics Technology editorial team since July 1972. In fact, for nearly 30 years, he led the editorial effort as Chief Editor. This issue marks the last one for Matt as a full-time member of the editorial team. Thankfully, we’re not losing him altogether; he will continue writing articles as a freelance contributor and will be part of the team heading to Orlando next May to report on NPE2024.

To those who claim plastics are harmful to the environment and deleterious to human health, I say this: Matt Naitove has plastics coursing through his veins. Matt joined Plastics Technology in 1972 with a B.A. in English Literature and an M.S. in Journalism from Columbia University and has contributed mightily to the brand’s current standing from day one.

The son of a surgeon, Matt pursued academic credentials in the arts while maintaining a keen interest in science and how things work, and his first exposure to the trade press came in the early 1970s. He recalls, “Before starting journalism school at Columbia University, I landed a summer job in a big New York public relations firm. One of my tasks was managing their extensive library of trade publications. I was astonished by the variety and specificity of these magazines. It was a vital piece of my education because Columbia never hinted there was such a thing as the trade press. Fortunately for me, I knew there were other options.”

So, he responded to a help wanted ad (remember those) in the New York Times. That brought him to PT, where he started as an assistant editor reporting on composites, additives and other topics. He became managing editor in 1978, where he was responsible for hiring, training and supervising editorial staff; scheduling all editorial; tracking editorial production through stages of editing, proofreading and layout; and copyediting all articles. And a few other things.

Mentoring young editors has been among his specialties throughout his career. I got in this business in the mid-1980s when there were maybe 12 or so different kinds of plastics publications. Early on in Matt’s career there were a few more. Back then, when one plastics pub had an editorial opening, they usually poached from a competitor. Matt more often than not took another path, hiring plastics newcomers — people with writing skills and some discernible technical or scientific aptitude, and then trained them up. Sometimes circumstances required that “cub reporters” got tossed into the deep end. Matt likes to tell a story of one editor who started the same week as an NPE: “I brought him to an exhibitor and showed him what a granulator is and what it does, and tasked him with finding everything new in granulators that week.”

His memory is encyclopedic. Ask him when a specific article appeared in the publication during his time, and more often than not he will know the year, month and sometimes even page number of the story in question.

In addition to writing his own articles, Matt is a technically savvy and skilled copyeditor. From 1978 up to the present, in fact, he has copyedited every page of the magazine. He helped shape a December 1979 special issue on a decade of safety and health regulations, for which PT received a Jesse H. Neil Editorial Achievement Award for Outstanding Journalism. I think among his many skills, Matt enjoyed copyediting the most. In fact, as we were putting this issue to bed, he emailed me a 1600-word document of his copyediting tips for the post-Matt era. I will need them.

Matt loves trade shows. It’s a good thing; he’s been to nearly 100 of them. These include 16 NPEs, 14 K Shows, five Japanplas/JP shows, four Interplas exhibitions, four Fakumas, one Plast Milan, many ANTECs, a few Plast-Ex Toronto shows, a PTXPO, and a number of regional U.S. plastics fairs and more specialized shows on composites, packaging or recycling.

If I haven’t convinced you yet of how much I respect Matt Naitove and all that he has given to this brand and the industry, let me add that I have nominated him for induction in the Plastics Hall of Fame, Class of 2024.

I would be remiss if I ended this without noting that Lilli Sherman will also be moving from full-time editor to contributor with this issue. Lilli started with PT in 1987 and has reported on ever-evolving materials and additive technologies. She also is responsible for our resin pricing column. She regularly covers advances in biopolymers, thermoplastic composites as well as testing/measurement, decorating/printing, and welding technologies. She also enjoys being a regular blogger on interesting technologies and studies that emerge in the news beats she covers. You have not seen the last of Lilli either, as we hope to continue to carry her byline and have her join us at NPE2024.

Godspeed, my colleagues.

Related Content

Business Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

Read More50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreRevisited: A Processor's Checklist for When Business Is Slow

Business slowdowns may provide you with more time for introspection. If you want to take a deeper dive into your operation, here are some things to consider.

Read MoreAttention Molders: Time to Get Serious About Sustainability

If you’re not looking at ways to make your injection molding operation more sustainable, perhaps you’d better get started.

Read MoreRead Next

50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More