Catheter Specialist Finds Sweet Spot Serving Small, Medium-Sized Concerns

Medical-component specialist LightningCath has carved a niche meeting the needs of small to medium-sized entrepreneurs with complex catheter designs … quickly.

When you have the word lightning as part of your company name, it’s likely your customers will expect products quickly. That’s a critical part of the mission at LightningCath, a manufacturer of catheter components based on the “medical alley” of Maple Grove, Minnesota. Spun out of medical-device manufacturer Switchback Medical, in May 2022, LightningCath quickly filled a niche for helping small- to medium-sized companies bring medical device products to market quickly.

“Our typical customer could just have an idea for a medical device,” says Matt Osten, a principal and co-founder of the company. “They might not have a print; they’re just getting started. So, we’ll brainstorm with them, spend a lot of time up front, bring them to our facility, and basically walk them through and teach them the process. And usually that helps us both understand what’s necessary to bring their idea to market.”

The medical component market is a huge, sophisticated and fast-growing space. On a global basis, market research firm Straits Research pegged the industry at more than $577 billion in 2022, and a projected compound annual growth rate of 5.1% through 2031. But, due to its dynamic nature, there is still room in the industry for entrepreneurs — some of them companies, while others clever engineers or even doctors — with nothing more than a concept sketched out on a napkin. That’s LigthningCath’s sweet spot, and it’s filled a need because these companies or individuals with ideas usually can’t get the bigger medical device firms interested in their projects.

Switchback Medical experienced this firsthand. Over the years, Brady Hatcher, Switchback CEO and co-founder of LightningCath, had received many requests from innovators deemed too small or too discreet for the bigger companies. Says Hatcher, “We saw a large unmet need in the medical device development and component manufacturing space. Innovators that need prototypes or extrusions were having challenges getting the service they would like from the large company options, and there are not enough small companies with these capabilities to support them.”

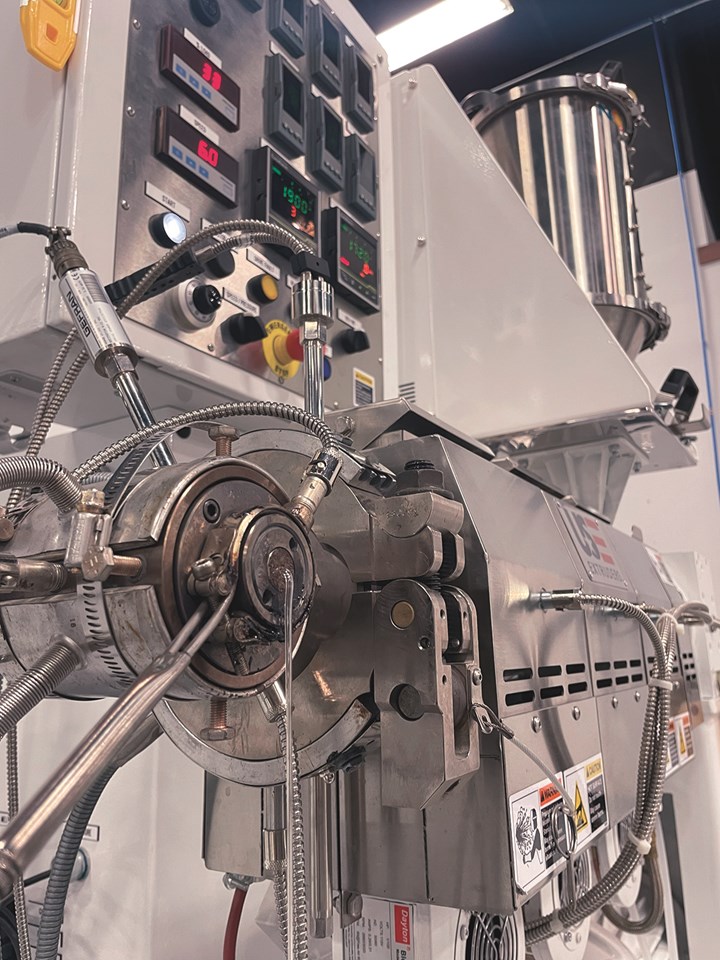

LightningCath’s facility is equipped with two extruders from US Extruders, including this new medical line. Photo Credit: LightningCath

So Brady moved Switchback out of the plant that LightningCath now occupies. It’s 19,000 square feet and has an ISO Class 7-certified, 5,000-square-foot cleanroom. LightningCath runs two lines with extruders from US Extruders, one purchased brand new and a second that Osten describes as “barely used.” LightningCath designs all of its tooling, utilizing machining services provided by Switchback.

LightningCath processes extruded tubes in a range of materials, notably PEBA, TPU, nylon and PE at ODs ranging from 0.010 inch to 0.500 inch at tolerances down to ±0.0005 inch. Additional capabilities include multilumen and bump/taper tubing. It also has a wide range of catheter assembly, metal processing and finishing capabilities, as well as complete catheters in steerable or fixed-shape formats.

Says Osten, “Our value proposition right now is prioritizing smaller and mid-size companies that can’t necessarily go to the bigger contract manufacturers because the bigger companies are working for the top-tier medical OEMs. LightningCath’s in-house catheter process equipment, thermoplastic and FEP heatshrink extrusion capabilities, experienced R&D and process engineers give us vertical integration and speed not typically seen by the smaller to mid-sized contract manufacturers.”

He adds, “The additional resources of Switchback’s 100-plus people, many of them catheter development engineers, along with its strong operations team, give us additional stability and security.” LightningCath plans to add PTFE etched liner extrusion capabilities in 2024, where Osten says it has particular expertise. Osten notes the company will soon be expanding into Costa Rica, where costs are lower. He states, “LightningCath is a well-rounded company with a great base. We’re excited to help our customers wherever they are — with quality and speed.”

Related Content

Wisconsin Firms Unite in Battle Against Covid

Teel Plastics opened new plant in record time, partnering with AEC & Aqua Poly Equipment Co. to expand production of swab sticks to fight pandemic.

Read MoreMedical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.

Read MoreArtificial Intelligence Enables Smarter Sourcing

Westfall Technik has adopted Arkestro’s predictive procurement software to wring savings and more reliable deliveries from a historically challenging supply chain.

Read MoreAs Currier Grows in Medical Consumables, Blow Molding Is Its ‘Foot in the Door’

Currier Plastics has added substantial capacity recently in both injection and blow molding for medical/pharmaceutical products, including several machines to occupy a new, large clean room.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More