Choosing the Right Projects to Automate

What are the strategies and upfront work that go into identifying production problems that could benefit from an automation solution?

Now is absolutely the right time to automate. Industry forces have never been stronger in pushing the industry toward that goal. Your customers are asking more of you, including more value-added to molded parts, as the shoot-and-ship world that we once knew is gone.

It’s daunting right now to find shop floor personnel — skilled or unskilled. The problem is exacerbated by the retirement of baby boomers coupled with the fact that not a lot of young people are coming into the plastics industry. In addition, we’re all competing against low-wage countries, and when those suppliers are asked to add more value to the parts, they can just throw people at the job.

There has also never been higher demand for quality and traceability, and luckily, the machinery on the market today can assist with that. The precise controls of the molding machines, robotics and automation, as well as the auxiliary equipment, all mean it’s a good time to make quality product. Your customers want you to improve and get better, and then they want those savings returned to them.

What level of automation are your competitors offering? You’re both going after that same customer, so how are they winning that work over you?

So why isn’t everybody getting there? What’s the issue? Most molders already have a solution to get product from the mold to a conveyor belt, whether that’s a simple take-out robot or using gravity and letting the parts fall. The real issue comes once those parts have left the mold and they’re on that conveyor belt — what do you do with them now? What if the parts are being pulled from older tools that weren’t designed with automation in mind? The cavities’ layout and how the products can be handled might not be a good fit.

Today, before mold steel is cut, there are a lot of conversations with engineering, automation companies and robotic engineers about the end goal. What are we going to do with this part? A lot of times, we can design the mold and the cavity layout to assist in reducing the cost of automation, avoiding added costs and other problems down the road.

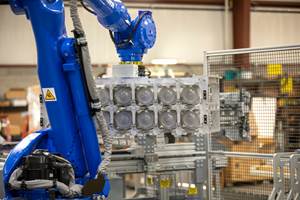

Pictured here is an RCII-150S-15-9.5 robot on a molding machine with an insert load station and changeover plates. An operator loads eight inserts every cycle into the station, and an EOAT picks up finished parts from the press and presents them to the operator. Photo Credit: Yushin America

Visual Inspection

The human being is a very precise, intricate machine — a person can do things very easily, especially assembling components — that a robot would struggle with. Their sense of touch, vision and hearing enable them to understand and interact with the environment around them. Robots don’t really have that. There are vision systems, and you can invest in high-end lenses and lighting that can “see” just about anything, but it’s not the complex vision of a human.

Even before a molder considers adding machine vision, automation doesn’t come cheap. A simple bowl feeder for insert molding, for instance, could run $50,000 to $60,000. Because of the high initial cost, you want to make sure that when you identify a project to automate, you identify it correctly and invest in automation that will provide a good return.

For custom molders, there are a lot of low-volume, high-mix jobs, requiring numerous mold changes and short runs. Obviously, this type of work can pose a challenge to automation. At the other end of the spectrum, high-volume always-running jobs where the mold is essentially welded to the platens, never coming out, are an easy win for automation.

Strategic Planning

Where does your company fit into the broader market? What kind of value-added operations are you currently performing or would you like to? What is your customer targeting, and what will you need to have for them? What level of automation are your competitors offering? You’re both going after that same customer, so how are they winning that work over you? When should the automation of specific operations take place and what’s the sequence — do you have the core competencies required for automation? These are all vital questions. Look at which operations can be automated profitably and under what constraints — don’t just go out and pick something randomly.

I’d suggest that initially you really assess the internal level of competency at your facility, examining your people and infrastructure. Once that is done, you can go about identifying the opportunities and evaluating the return on investment for each of them.

It doesn’t take anything more than two guys in a garage to call themselves an automation company, knock on your door and say, “Hey, I’m right down the street, and I can help you with all your problems.”

Part of this self-evaluation involves assessing what you currently have for automation. Do you have sprue pickers; are you separating runners from parts; are you just dropping parts on a conveyor; have you automated your material handling system and your drying; and what does the movement of finished product around your facility look like?

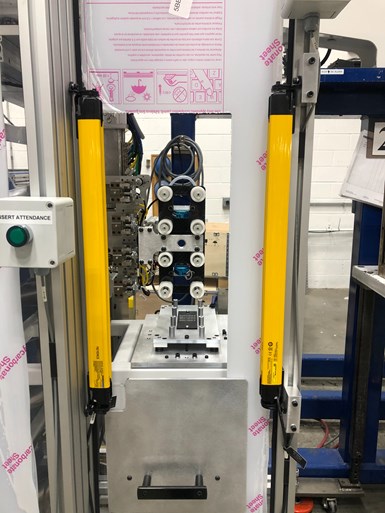

An 8-cavity dual-purpose EOAT removes finished parts with runners and places inserts into the mold. The parts are collected by individual cavities into separate totes and containers. The process has a cycle time of 30 seconds, with sensors used to detect container presence.

Photo Credit: Yushin

You also need to look at the company’s culture from the top down, CEO to shop-floor employees. Is there a fear of automation? Is there anxiety that this robot is going to take my job or, in the executive suite, is the CFO saying this is way too much money to invest? Answering all these questions will give your supplier a good understanding of where your company is and what your employees are capable of handling, as you move down the path of design fabrication.

Eventually, you’re going to get something installed on the floor and up and running, with the help of the installation team from the supplier. But what happens when they leave and you’re doing your first mold change? If you had to move the equipment off the machine, once the job is up again, you must recall your alignment and installation protocol to get the cell back into operation.

As you evaluate your internal competencies, consider your employees’ age. Do you have a younger workforce, including engineers and technicians that have grown up since birth with mobile phones, tablets and computers? Or do you have an older workforce where a lot of the technologies that they’re used to are more mechanical? The basic troubleshooting elements — electrical, mechanical, hydraulic, pneumatic — are all still in the mix, but now you’re getting into a higher level of electronics and drives and communication protocols.

Project Management Team

For the project management team, you’re going to want to bring together a fully representative group from the top down. Get your president involved, as well as marketing, quality managers, the inventory team and maintenance people. Include everybody that’s going to be a stakeholder in this project because they all must have buy-in.

Whether you’re figuring out a place to store your end of arm tools (EOAT) or determining how you’re going to get boxes of finished product to the palletizing area, it all must be thought through with everyone’s approval and feedback.

Define all your savings and write detailed specifications out for your internal team and for the outside vendor, so there is no finger pointing, questions, misunderstandings or assumptions. Establish a time line of milestones and understand what it’s going to take to get the automation on the floor.

All this needs to happen because if you lose a month or two in implementation of the system, that’s going directly against your ROI and your customer’s expectations. Ensure that the timelines within your automation policy, which will establish a focus and direction, avoid any confusion in what’s being purchased; and identify who’s managing various aspects of the projects.

Calculating ROI

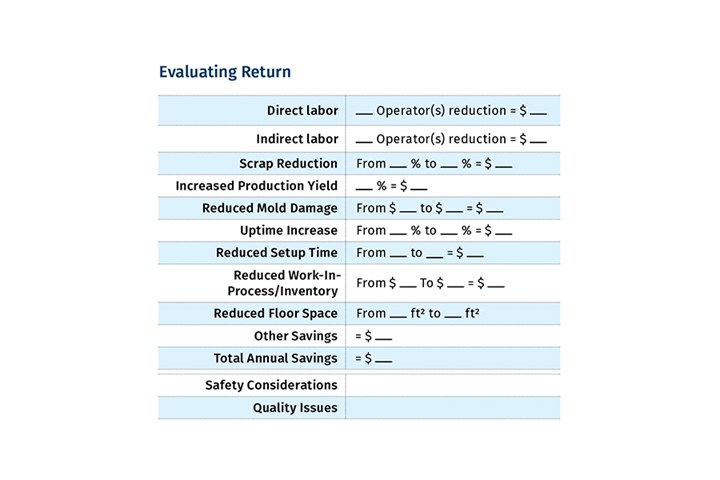

To evaluate your return, you’re going to look at your direct and indirect labor savings. Consider any people that are touching the product, and then look at quality and where your scrap reduction can be found if you’re currently just dropping parts. If they’re getting scuffed by hitting each other or a conveyor rail, or being contaminated by grease on a tiebar, with automation all that goes away.

An automation partner or supplier could be come in various forms. You might just need someone to help you with engineering, if you have a machine shop and assembly capabilities but require design assistance.

A number of factors must be accounted for when determining the ROI impact of automation a process. Photo Credit: Yushin

Go and visit with potential partners and understand what they’re all about. You should also have them come in and visit your facility to make sure there’s a fit. Understand what kind of experience potential vendors have — what kind of projects have they worked on previously? See if their prior work is of equal or greater complexity to what you’re asking them to do and find out what their project management systems procedures look like, including sign-offs, validations and runoffs.

In reality, it doesn’t take anything more than two guys in a garage to call themselves an automation company and come knock on your door and say, “Hey, I’m right down the street, and I can help you with all your problems.” Qualification of any vendor is a must.

Low-Hanging Fruit

Once you’ve determined if you’re going to venture out on your own or go forward with the help of a partner, you need to look around your facility and find the low-hanging fruit for automation, or projects where you’ll get the most bang for your buck. A good place to start is any job involving labor savings.

Once those types of projects are located, it’s smart to piece them out because taking on one big chunk of value-added operations in a single step is likely too much to swallow. Chop it up a bit and automate simple parts of the bigger whole.

A huge benefit of a take-out robot and an EOAT is that the parts are captured, aligned and oriented. This means you can use the leftover cycle time of the process for inspection, trimming, degating, weighing and more. If parts are ejected and allowed to free-fall onto the conveyor, you must reorient them to perform any other operations on them.

It is far easier to absorb any issues with project timing when it’s communicated early on, so running a communication log is a good idea.

Moving forward, look for part families that are similar. Maybe they’re not identical, but the cavitation is close and the part geometries are roughly approximate. In these cases, you could have one EOAT working across three or four different molds just by making minor changes to it between jobs. Alternatively, you could have an EOAT with A, B and C positions where you make small adjustments so they can perform multiple tasks across multiple tools.

Automation Phases

It can be helpful to think of automation as a series of progressively more complicated phases. Phase zero would be no automation or maybe a sprue picker. Phase one is basic pick and place, grabbing a part and putting it on a conveyor. Phase two would be one secondary operation, maybe cutting a runner off or trimming gates. Phase three involves more value-added operations, which could include picking, inspecting and placing inserts into the mold while removing finished parts with a dual-function tool.

Eventually you can build toward a full-blown flexible manufacturing system, with multiple machines providing parts and multiple conveyors transferring those parts between presses. In these instances, there’s the potential for a great deal of communication data protocol and data collection from the machines to an ERP system.

As a partner, if a customer asks us to come in and talk to them about an automated solution, and we assess that they’re in phase zero or phase one and they want to jump into phase four or five, we try to pump the brakes, slow down a little and look at some more incremental steps.

Scope of Work

When it comes time to write out the technical specifications and scope of work, you’ll need to completely lay out the system, covering everything from the floor layout to the broader environment, including potential obstructions such as pipes, water lines and electrical conduit.

From our perspective, we coach our technicians when they’re on-site to look a step downstream and a step upstream to fully understand the full manufacturing sequence. Eventually you’ll get all your system components laid out, starting with basic elements like side- or top-entry robot, safety guarding, conveyor, feeder system and more, making sure the whole time that everything can match the quoted cycle time. Controls requirements, including the operator interface, must also be considered, and important questions include: will you use Ethernet IP, discrete IO and what communication will go out from the automation and will there be data collection? Machine and industrial safety standards must be considered and applied, including safety guarding and good manufacturing practices for areas such as electrical, pneumatics, labeling and traceability.

Throughout this process there should be constant communication between your vendor and your internal team, including project management notes that are kept in a shared spreadsheet or folder. Critical items to be discussed include milestones, with color coding of process achievements. If something gets out of line, say a critical part is stuck on a boat in the Panama Canal, you want to identify that quickly and let everybody know right up front. It is far easier to absorb any issues with project timing when it’s communicated early on, so running a communication log is a good idea.

In this system, the eight collection tote containers can hold up to 8 hours worth of parts in the separation station. Each tote corresponds to a specific cavity in the mold, with tubes separating out parts by cavity and sensors detecting the presence of a container. Photo Credit: Yushin

Engineering Design Review

Applying 3D design software enables reviews to take place remotely in an online environment. This started with the COVID-19 pandemic but has become broadly accepted so that many runoffs are done through video with design review in a Zoom or Teams meeting. The 3D design software enables users to flip components in any direction and get a view from all sides. Complex systems can be exploded out to the individual component level.

Finally, you’ll want an installation plan, including a complete understanding of expectations. The facility must be ready to go — there’s nothing worse than having an installation team show up, and you didn’t have the electrician run in power where it’s needed so you lose a couple of days. Once the robot is installed and running, you need to make sure it’s producing the way it should be. Acceptance or validation testing could be a factory acceptance test with your vendor, including final acceptance on-site once it’s all in operation.

About the author: National sales manager at Yushin, Chris Parrillo has worked for Yushin America for the past 28 years in various technical and sales roles. He has extensive knowledge in implementing robotics and automation systems for plastic injection molding applications, working with molders across several industries. In his current role, he oversees the sales and marketing activities for North America. Contact: cparrillo@yushin.com; 401-463-1800; www.yushin.com

Related Content

50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreAutomation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreAn Automation 'First' for Non-Servo-Eject Trim Presses

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreRead Next

How COVID-19 Did (and Didn’t) Change Automation in Plastics

The global pandemic invigorated longstanding trends and new market forces to push broad-based adoption of automation and robotics from the incremental to the inexorable.

Read MoreEnsuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

Read MoreSmarter & More Collaborative: Yushin Taps into Two Major Robot Trends

New Yushin robots have Industry 4.0 features and collaborative capability.

Read More

.png;maxWidth=300;quality=90)