Color Compounder Enters Market with a Bang

To get noticed in the color masterbatch business—particularly in white—you’ve got to start big. That, and new technology, form the foundation for startup Neko Colors

Say this about Neko Colors Inc.: When they decided to open their doors in late 2013 they didn’t just dip their toes in the water. They did a cannonball.

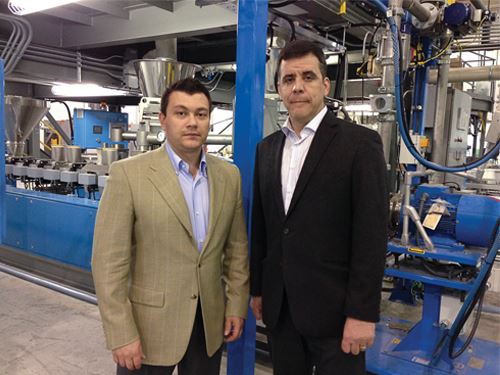

Based in a 40,000 ft² facility in LaSalle, Que., this startup color compounder knew going in that if it was going to be a success in supplying white, color, and additive masterbatches—primarily for polyolefins—it was either all-in or not at all. “Our capacity is 25 million lb/yr, and that’s just in white,” states Dmitry Korenblit, part of Neko’s family ownership team.

“We’re unique in the sense that most color houses usually start up on a much smaller scale,” adds Ron Stark, Neko’s v.p. of operations. “But as the new kid, we made the decision right away that if we were to compete against long-established players in the market we could not do so in a small way. Especially in the white masterbatch business, you have to be big to get noticed.”

Korenblit and Stark are among the 10 people Neko currently employs. Both have entrepreneurial backgrounds in manufacturing, chemicals, and distribution. Stark began his career with a masterbatch company that was subsequently bought by Spartech (now part of PolyOne).

Neko made another strategic decision when it opened shop: It bought brand-new equipment. “It would have been easier and less expensive for us to buy used equipment, and there was plenty of it on the market,” recalls Korenblit. “But again, in an effort to differentiate and make it clear how serious we are, we went to the K2013 show in Dusseldorf last October looking for state-of-the-art German-built equipment.”

The new firm opted for three high-speed, high-torque Maxx extruders from Leistritz (U.S. office in Somerville, N.J.; leistritz-extrusion.com). Neko would not divulge the sizes of these machines. It did note that the first two were commissioned within three months after a purchase order was issued. The third extruder—the largest of the trio—was being brought on line as this article went to press. All are equipped with multiple feeders and are fully automated “from silo to packaging,” as Korenblit puts it. The facility has room for three additional lines, Stark adds, noting that Neko expects to double its workforce before long.

Locating its plant in Quebec made sense for Neko for a number of reasons. Explains Korenblit, “First, there is a big customer base of molders and film extruders in the province, and no one is manufacturing product at the scale we are planning. Second, the transportation infrastructure in Montreal is excellent, with easy access to shipping by rail, sea, and air.” Neko’s plan is to sell throughout North America and around the world.

Adds Stark, “When we were formulating our plan, we looked at getting in the business by buying a competitor. But starting from a fresh piece of paper and getting the best technology into the building from day one made better sense. We made an outstanding product from the first pound, and we have the solid financial backing, technical expertise, and great mix of people to grow the business moving forward.

Related Content

A Recycling Plant, Renewed

Reinvention is essential at Capital Polymers, a toll recycler that has completely transformed its operation in a short period of time.

Read MoreInjection Molder Bases Company Culture on Employee Empowerment

After more than two decades in the industry, Rodney Davenport was given the opportunity to create an injection molding operation in his own vision, and — in keeping with the product he was making — to do so from the ground up.

Read MoreBack in the Family Business

In its 45th year, Precision Molded Plastics has carved out a technology and market niche, growing not just when opportunities arise but when they make sense, after its leader changed careers to keep the family business from changing hands.

Read MoreMatrix Tool: Welcome to the Family

In its 50th year, Matrix Tool applies moldmaking and injection molding expertise, plus a long family heritage, to high-precision jobs that many would deem impossible.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More