Compatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

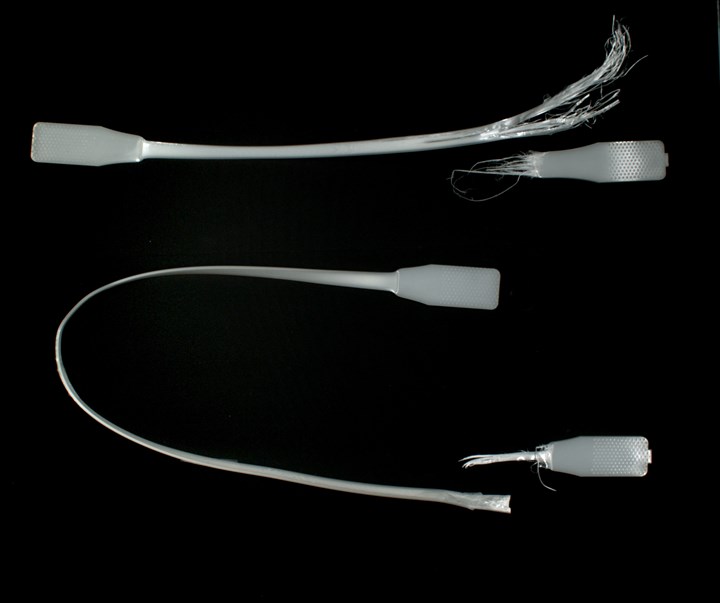

Recycled HDPE/PP sample without Dow’s Engage compatibilizer (top) and recycled HDPE/PP sample with Engage POE compatibilizer. Elongation at break is increased by a factor of 3 with compatibilization, from 130% to 450%. (Photo: Dow)

With plastics recycling now a global growth market, compatibilizing resins and additives are increasingly being used to address challenges in using mixed resins for applications ranging from packaging and consumer goods to construction, agriculture and automotive. Enhancing material performance, improving processing, and reducing costs and environmental footprint are among the key objectives, with large-volume commodity plastics such as polyolefins and PET leading this activity.

One major hurdle for using recycled material has been the costly and time-consuming separation of incompatible plastics. By enabling incompatible plastics to mix in the melt, compatibilizers help reduce the need for separation and provide materials manufacturers the potential for higher-quality outputs, along with cost reduction due to increased recycled content and access to new lower-quality, low-cost sources.

Among these compatibilizers for recycling are specialty polyolefin elastomers, styrenic block copolymers, chemically modified polyolefins, and additives based on titanium-aluminum chemistry. Other new products have also emerged. Expect all of these to be center-stage at upcoming industry trade shows.

Dow says Engage POEs and Infuse OBCs are best suited for compatibilizing HDPE, LDPE and LLDPE with PP, thanks to the PE backbone and alpha-olefin as comonomer.

(Photo: Dow)

Polyolefin Elastomers as Compatibilizers

Specialty polyolefin elastomers (POEs) and polyolefin plastomers (POPs), which were launched initially to boost properties such as impact and tensile strength of polyolefins, have been making inroads as compatibilizers for recycled PE and PP, sometimes together with other materials such as PET or nylon.

Such products include Dow’s Engage POEs, ethylene-based random copolymers with alpha-olefin comonomers; and Infuse OBCs, olefin copolymers with alternating blocks of hard and soft segments; as well as ExxonMobil’s Vistamaxx propylene-ethylene and Exact ethylene-octene POPs.

These products are sold to plastics recyclers/compounders and other processors, according to Jesús Cortés, market developer of product solutions at ExxonMobil, noting that compatibility can be a key enabler to help recyclers use cross-contaminated and potentially low-cost, polyolefin streams. Says Han Zhang, global sustainability director for packaging and specialty plastics at Dow, “Our customers benefit from creating higher-quality end products while accessing a broader recycle stream. We serve processors that use compatibilizers to increase recycled content while maintaining processability.”

“Our customers benefit from creating higher-quality end products while accessing a broader recycle stream.”

ExxonMobil’ Cortés confirms that the same Vistamaxx and Exact grades applicable for virgin-resin modification are used for compatibilizing recycled plastics. He notes that Vistamaxx polymers compatibilize HDPE, LDPE and LLDPE with PP, adding that due to the polarity of polymers such as PET or nylon, a grafted Vistamaxx grade is required to effectively compatibilize polyolefins with such resins. “We work with several compounders that graft Vistamaxx to compatibilize polyolefins with nylon, for example, while looking to maintain the performance improvements that Vistamaxx polymers could bring to the compound formulation.”

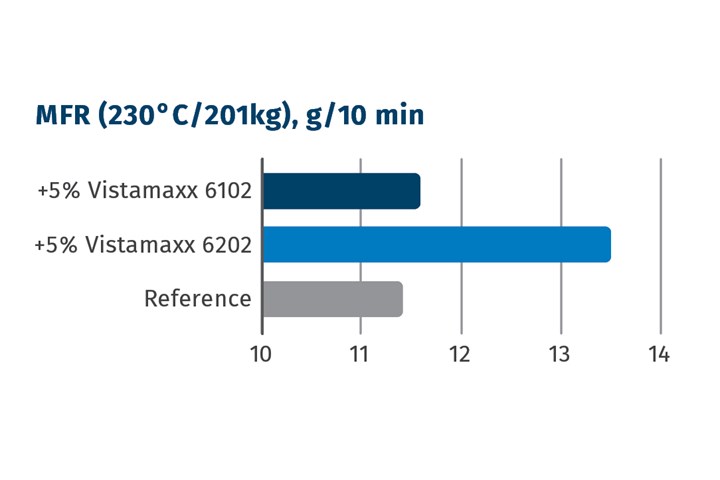

FIG 1 MFR graphs shows a blend of mixed-color recycled HDPEand PP, with and without Vistamaxx compatibilizer. (Source: ExxonMobil)

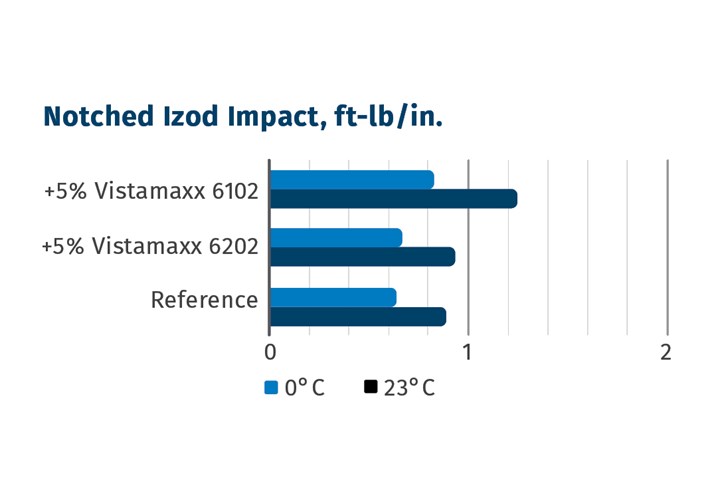

Cortés says compatibility can be confirmed by an increase in mechanical performance, such as highly desirable impact resistance. Increasing flow is also of interest when repurposing materials—an example would be developing an injection molding formulation from an HDPE bottle stream. He notes that all the specialty elastomers currently available have their uses. “Rather than comparing their general efficiency, the discussion should be framed towards picking the tools that are best suited for a particular project.”

For example, he says, “When compatibilizing PE with PP, we’ve seen better results with Vistamaxx. But the market is also in need of impact property improvement, where ethylene-octene plastomers can have a fit when seeking low-temperature impact strength.”

Cortés adds, “The loading levels are quite similar both for ethylene-octene plastomers such our Exact grades or Dow’s Engage, as well as for our Vistamaxx.” ExxonMobil approaches most projects with a 5% loading and then increases or decreases the amount as required.

Dow’s Zhang explains that while the presence of PP in HDPE typically improves stiffness as measured by flexural modulus, it compromises toughness as indicated by impact strength and tensile elongation, due to the incompatibility of the two components. The use of compatibilizers for such HDPE/PP mixtures improves the stiffness/toughness balance through reduced phase separation and improved interfacial bonding.

FIG 2 Impact-strength graphs shows a blend of mixed-color recycled HDPE and PP, with and without Vistamaxx compatibilizer. (Source: ExxonMobil)

Zhang says Engage POEs and Infuse OBCs are best suited for compatibilizing HDPE, LDPE and LLDPE with PP, thanks to the PE backbone and alpha-olefin comonomer. As a compatibilizer for PE/PP mixtures, they are typically used at 2% to 5% by weight. Zhang notes that by improving the balance of the stiffness and toughness, Engage POE compatibilizers (e.g., grade 8100) enable higher-value applications for mechanically recycled PE/PP mixtures, including both PE-rich and PP-rich waste streams. Applications include injection molded auto parts, paint cans, trash bins, shipping crates, pallets and outdoor furniture.

The market needs impact-property improvement, where ethylene-octene plastomers can have a fit when desiring low-temperature impact strength.

He adds, “The addition of as low as 3 wt% Engage 8100 improves impact strength and tensile elongation of un-compatibilized HDPE/PP 70/30 mixture by a factor of three, while maintaining the higher modulus imparted by the PP component.” He adds that for demanding low-temperature ductility applications, Engage POEs enable sub-ambient temperature toughness due to their extremely low glass-transition temperature.

Addressing the cost of these specialty elastomers, ExxonMobil’s Cortés says, “Balancing cost and performance is important in the highly competitive recycling value chain. With Vistamaxx polymers, the performance of recycled resins can be improved, enabling the resins to be used in applications where there’s potential for the recycler to extract a higher economic value while serving the demand for higher-performing materials. As a result, recyclers may have broader opportunities to market their recycled plastic beyond cost as the primary driver, enabling them to focus instead on custom-tailored compounds and performance.”

Zhang notes, “In addition to enabling the recycling of mixed polyolefins, we are committed to advancing recycling of a broad range of mixtures such as polyolefins with engineering plastics like nylon and polyesters. We already have a range of functional polymers to offer but continue to actively develop new solutions to address the diverse plastic mixtures encountered in packaging, infrastructure, transportation and consumer applications.”

Styrenic Block Copolymers and Chemically Modified Polyolefins

Styrenic block copolymers and chemically modified polyolefins are other types of materials that have been gaining attention as compatibilizers for recycled resin enhancement and compatibilization.

Kraton Polymers offers its CirKular+ styrenic block-copolymer platform of performance-enhancing additives for plastics upcycling and recycling. Yuliya Streen, Kraton specialty-polymers global strategic-marketing director, points to two series with five grades: CirKular+ Compatibilization Series (C1000, C1010, C1010), and CirKular+ Performance Enhancement Series (C2000 and C3000). These additives represent a family of block copolymers based on styrene and ethylene/butylene (SEBS). They boast superior mechanical properties, including high impact strength at room or low temperatures, flexibility in tailoring stiffness and impact properties, enhanced stress-crack resistance, and improved processability. The Circular+ products also offer multi-resin compatibility across virgin plastics, PCR and PIR waste streams. Depending on the grade, they can be used for PP, HDPE, MDPE LLDPE, LDPE, PS and HIPS, and polar resins such as EVOH, PVA and EVA.

“We have shown that both recycling and upscaling polyolefin mixed plastic waste into higher value products is possible.”

Says Streen, “Fully reprocessable CirKular+ additives enable upcycling of PCR by enhancing mechanical properties and supporting polyolefin-based monomaterial product designs, allowing for maximization of PCR content to over 90%. Plastics modified with CirKular+ show better reusability after undergoing multiple cycles of mechanical recycling due to less degradation of physical properties than unmodified resins. Tests have shown up to five-times thermal reprocessing of CirKular+ products, enabling multiple reuse.”

The CirKular+ Compatibilization Series are multi-resin compatibilizers for upcycling mixed PCR and PIR recycling streams at typical addition levels of 3% to 5%. Two examples of mixed-waste reusability include compounded and injection molded samples of 76%-PCR HDPE + 19%-PCR PET + 5% Kraton+ C1010; and a sample of 72%-PCR PP + 18%-PCR PET + 10% Kraton+ C1000. In these examples, notched Izod impact strength increases by 70% and 50%, respectively, and yield strength increases 40% and 30%, while retaining stiffness and improving processability. Similar efficacy has been shown in PCR LDPE-PET blends. These products are also effective with nylons and ABS.

The CirKular+ Performance Enhancement Series are aimed at upcycling mixed PCR and PIR polyolefin and PS streams at typical addition levels of 3% to 10%. One recent successful injection molded test was of a 91%-PCR PP + 9% Kraton+ C2000. The formulation showed an increase of 110% in impact-modulus balance over competitive products. Says Streen, “This type of enhancement is required for high-performance rPP applications in automotive and industrial sectors. This can also be applied for packaging, but the C2000 dosage would be lowered due to less stringent requirements.”

Streen says Kraton+ materials can be pre-compounded or dry blended with the recycled plastics before molding or extrusion or as part of the recycling process. Since the launch of CirKular+ just a couple of years ago, the firm has seen early adoption across applications including industrial pallets, food and beverage packaging, automotive components and infant car seats. CirKular+ can also be used in various processing techniques including injection or compression molding, extrusion, rotomolding, and compounding.

Part of the extensive range of Polybond chemically modified polyolefins from SI Group that serve as coupling agents and compatibilizers is Polybond 3150/3002, a maleic-anhydride-grafted PP that can compatibilize recycled PP with all types of nylons. At typical use levels of 5%, it has been shown to improve notched Izod impact strength and Reverse Izod impact performance by more than threefold, according to John Yun, technical-service and technology manager. Director of market development Irfaan Foster notes that an initial application was automotive noise insulation. More recently, it has been used in recycled PP/nylon mixtures for under-floor panels, underhood components and behind instrument panels.

Another grade is Polybond 3029, a maleic-anhydride grafted HDPE launched two years ago as a compatibilizer for wood-plastic composites. It appears to be promising for compatibilizing 50/50 PCR/virgin HDPE mixtures, says Yun.

Titanates & Zirconates

Yet another class of compatibilizers are based on titanium-aluminum chemistry, such as titanate (Ti) and zirconate (Zr) catalysts offered by Kenrich Petrochemicals and sold to compounders and molders. Among the company’s offerings is a novel catalyst available in masterbatch or powder form, which acts as compatibilizer for dissimilar polymers, including polyolefins, PET, PVC, and bioplastics like PLA. According to Sal Monte, Kenrich president and co-owner, it has gained increasing attention for use in PCR mixtures such as PP/PET/PE. And it reportedly has been shown to boost extrusion output and lower cycle times in injection molding.

Ken-React CAPS KPR 12/LV pellets and Ken-React KPR 12/HV powder reportedly have been shown to regenerate PCR to virgin-like properties. The product is the result of combining the company’s neoalkoxy LICA 12 titanate catalyst with a mixed-metal catalyst to “give more bang for the buck,” says Monte. “We offer the application of 1.5% to 1.75% CAPS KPR 12/LV pellets by total weight of all recycle materials added to the hopper just like a color concentrate, and lowering the process temperatures 10% to 20% to maintain reactive compounding shear. They work at the nano level, so reactive compounding shear is needed and high torque is needed in the melt.”

According to Monte, these additives are efficient compatibilizers for addition polymers (e.g., LLDPE and PP) and condensation polymers (like PET), organic and inorganic fillers, and bioplastics like PLA. Typical results include 20% faster processing at 9% lower temperature for extrusion, injection and blow molding of most unfilled thermoplastics. Similar results have been achieved with recycled 80/20% LDPE/PP mixtures. In one case, CAPS KPR 12/LV at 1.5% was used to compatibilize three PIR resins: LLDPE from a fractional-melt film, PP copolymer from mixed 20-35 MFI injection molded caps, and PET from thermoformed clamshell food packaging. The PP/PET/PE mixture was ground into ¼-in. to ½-in. flakes and melt compounded into pellets for injection molding.

Interface Polymers’ patented di-block copolymer additive technology reportedly overcomes inherent molecular level non-compatibility between polyolefins to enable them to be recycled. (Photo: Interface Polymers)

Other Developments

The Distribution Business Unit of SACO AEI Polymers is an exclusive distributor for Fine-Blend of China, which produces a broad range of compatibilizers and chain extenders for PP, nylon, PET, engineering thermoplastics, and biopolymers such as PLA and PBAT—including recycled mixtures—according to business-unit manager Mike McCormach. The additives include non-reactive compatibilizers, most of which are block copolymers and graft copolymers or random copolymers that do not participate in chemical reactions during polymer mixing. One example is BP-1310, which has been shown to improve compatibility of recycled PP/PS mixtures at 3% to 5% addition levels. An additive for compatibilizing recycled PE/PS mixtures is in development.

Fine-Blend’s reactive compatibilizers, which improve compatibility by chemically reacting with the main polymer during mixing, include ECO-112O for recycled PET, PC and nylons; HPC-2 as a compatibilizer for ABS with recycled PET; and SPG-02 to compatibilize PP and recycled PET. They contain epoxy groups, which can react with hydroxyl groups on recycled polyester to increase viscosity and compatibility, says McCormach. There is also CMG9801, a maleic-anhydride-grafted PP, which can react with the amino group of nylon.

Since 2016, U.K.-based Interface Polymers Ltd. has developed its patented Polarfin di-block copolymer additive technology, which reportedly overcomes inherent molecular non-compatibility between polyolefins to enable them to be recycled. These di-block additives are for use with virgin and recycled PE and PP compounds, sheet and films.

One project is underway with a major producer of film for recycling multilayer films without significant loss of properties. Even at low addition levels, Polarfin has been shown to eliminate gels—a common problem that has inhibited recycling of polyolefin films using recycled mixed plastics, according to business-development director Simon Waddington. “We have succesfully shown that both recycling and upscaling polyolefin mixed-plastic waste into higher-value products is possible using our Polarfin additive technology.”

ExxonMobil’s Cortés says compatibility (e.g., Vistamaxx in recycled PE/PP) can be confirmed by an increase in mechanical performance, such as impact resistance.

(Photo: ExxonMobil)

Related Content

Bringing Recycled Film into Food Packaging

FDA gives nod to recyclers, opening market to food safe packaging films from diverted materials.

Read MoreResins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

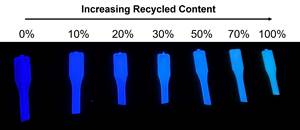

Read MoreFast, Simple QC Method Directly Quantifies Recycled Content in Plastics

Novel fluorescence-based spin-out technology provides a rapid and reliable method to measure and certify recycled content in a wide range of plastics.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreRead Next

Additive Supplier, Film Processor Get Grant to Advance Multilayer Film Recycling

Interface Polymers and Flexipol awarded $1 million+ grant to provide fully recyclable LDPE multilayer packaging.

Read MoreNew Metallocene TP Elastomers Tackle Films, Fibers, TPOs

The Vistamaxx family of propylene-ethylene specialty elastomers recently unveiled by ExxonMobil Chemical (see Your Business In Brief, August 2003) holds promise in a broad range of applications from very soft fabrics and films to very hard TPOs.

Read MoreTwo Dow Flexible Packaging Technologies Among R&D 100 Awards

Both the PE Stand-Up Pouch and PacXpert bottles are making commercial advances globally.

Read More