Extruding Very High-Flow Polymers

Screw designs not suited to process lower-viscosity materials will result in poor melt quality and lower outputs.

There are two main things to consider when processing very high-melt-flow polymers—the increased difficulty of melting them and the magnified effect of head pressure. This column will discuss melting.

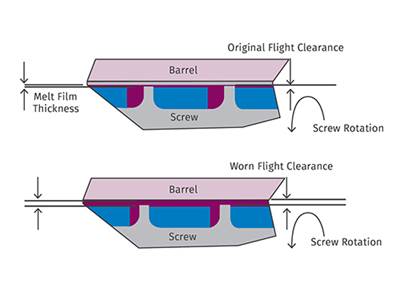

When the melt flow is very high, that means the melt viscosity is very low. The screw design usually has to be changed to accommodate that difference. As I’ve noted in previous columns, melting in a single-screw extruder occurs primarily as a result of viscous dissipation (or shearing) of the polymer (see illustration). In both a conventional flighted screw or a barrier screw, the melting principle is essentially the same. The unmelted polymer gets dragged against the barrel wall by the rotation of the screw, developing shear stress in the solid resin. This heats it up to begin melting. Continued melting is facilitated by the compression or declining channel depth of the screw, which brings the solids nearer the barrel wall to create a renewed region of viscous polymer, where shear changes the mechanical or rotational energy into heat in the polymer.

There are many other interactions going on in the screw channel simultaneously, but let’s keep things simple and stay with the basic melting process. Once melting starts, there is always a film of melted polymer against the barrel wall. All of the shearing force or drive torque must then be transferred through that melt film. The less viscous the film, the lower the resistance to screw rotation, and the lower the power entering the system from the drive. The result is that it is harder to transfer the energy necessary to raise high-melt-flow polymers to their processing temperature. Yet high-flow resins require a similar, if not identical, amount of energy per pound to reach their processing temperature—the same as low-flow polymers, in fact, since their specific heat is largely unrelated to the melt flow rate (MFR).

The solid polymer turns with the screw just like a stripped wood screw. Think of a solid cylinder comprised of the screw and the solid polymer turning inside a hollow cylinder with a viscous film between. That should make it clear that much of the force or torque required to rotate the screw, regardless of its design, is dependent on the resistance of the melt film. As the viscosity of the film decreases, it becomes easier to rotate the screw. The easier it is to rotate the screw, the less power it takes to do the rotation and the less power is going into the polymer. In fact, for a given screw design, the only variable to energy input from the drive is the viscosity of the film along the barrel if conducted heat in/out through the barrel is eliminated from consideration.

To compensate for the lowered viscosity in the film, the screws need to have lower specific output (output/screw revolution-hour). This allows for more energy per unit of output to enter the system as the specific output is reduced to compensate for the reduced viscosity. Other changes in the screw design can also be beneficial, such as longer screws, more aggressive compression, and high-shear mixing sections.

The fact that all the energy entering the system from the drive must pass through the melt film is a concept that is not generally understood by many operators, who unfortunately still believe the heat transfer is primarily from the barrel heaters.

In previous columns I noted that for very small screws (smaller than 2 in. diam.), conducted heat from the barrel should be a consideration, but as screws increase in size it shrinks to a minor effect. For example, a typical 4.5-in., 30:1 L/D extruder with a 250-hp (or 186-kW) drive would be equipped with 70-85 kW of barrel heating. If all the heaters were on all the time and normal heat-transfer efficiency prevailed, the heaters would only account for 20-30% of the energy available from the 250-hp drive.

When planning to process very high-flow polymers, be sure to review the screw design. If it’s not suited to the lower viscosity, it can produce poor melt quality and reduced outputs. Don’t expect the same level of performance from your low-melt-flow screws just because it’s the same polymer type.

ABOUT THE AUTHOR: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact: jim.frankland@comcast.net or (724)651-9196.

Related Content

Sizing Your Granulator To Optimize Scrap Reuse

What makes good regrind, and why is it important? Ideal regrind should be as close to pelletized material as possible, meaning regrind that is uniform and homogeneous, with minimal dust, fines and longs. Learn how to find the right granulator for your scrap.

Read MoreICYMI: March Roundup

Still catching up post-PTXPO? Whether you attended the show or not, there were bound to be some must-read articles that may have slipped past you. Catch up on what you missed.

Read MoreShredding Thin Film: How to Do It Right

While many processors recoil at this task, a little know-how in shredding equipment, processing, and maintenance should add the necessary confidence.

Read MoreICYMI: May Roundup

May was a busy month, especially with the buzz coming out of the Extrusion Conference. Here’s a quick look at the top articles from May you might have missed.

Read MoreRead Next

Do You Have Screw Wear?

It’s generally caused by metal-to-metal contact, and your first indicator will be poor melt quality.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More

.jpg;width=70;height=70;mode=crop)