For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

A lot has changed at the Plastics Industry Association since Matt Seaholm took over as president and CEO of the trade association about two years ago. Internally, under his leadership PLASTICS has brought in new, high-level talent. Externally, plastics is relentlessly attack by those who’d rather see the material banned.

As he heads into his first NPE in his current leadership role, Seaholm reflects on these changes, challenges and the solutions attendees should expect to see at the show in this exchange with Plastics Technology.

Plastics Technology: It’s been two years since you took over as president and CEO of PLASTICS. Catch us up on how the association has changed, or even advanced, since you took the job. Seems to me that you have brought in a lot of new, high-energy talent.

Seaholm: We have, and I am really proud of the team we are building. At the heart of it, we are the Plastics Industry Association. Our members need us to be a strong voice on behalf of them and the entire supply chain in America. It’s no secret that our industry has challenges, and a lot is being thrown at us in the way of attacks and misinformation. We don’t have the resources that all of the anti-plastics activist groups have, so we needed to hire high-energy professionals to craft and deliver positive messages about all that plastic does for society and to help lead the industry toward a more sustainable future.

The biggest changes at PLASTICS really stem from the renewed focus and prioritization that the board has directed us in advocacy, communications and sustainability. Our association is more active today than we have ever been, and I believe I will be able to say that every year for the foreseeable future.

Q: You came to your current position at PLASTICS with years of experience in trade association management, advocacy and even politics. How have these experiences influenced how you have positioned the association, and where you want to direct it in the future?

A: That is true — my career route toward head of this organization was certainly not a straight line. I have been fortunate to have a lot of different experiences throughout my career, but so many of them have helped prepare me for this role. I really cut my teeth as a campaign manager on political campaigns — thinking about every different aspect of an operation in an effort to persuade and motivate. In many regards, that’s still how I think today.

Having just passed my seven-year anniversary at PLASTICS, I get to apply what I’ve learned from our members and my colleagues over the years to advocate for an industry I am very proud to represent. You’ll continue to see our organization grow with a sense of urgency and focus, because that’s just how I am built.

Q: What are the biggest challenges the industry is facing now, and what resources is PLASTICS marshaling to meet these challenges?

A: Besides macroeconomic pressures, the biggest challenge we face is the commitment of anti-plastic forces to stop the production of plastic — regardless of whether it is good for society or even the environment.

As an industry, we are dedicated to eliminating plastic waste and preventing plastic waste from getting into the environment. We believe the best way to do that is by reminding people that plastic material is too valuable to throw away. Unfortunately, the shouting from the activist groups to just ‘ban it’ isn’t a constructive approach. We need partners by our side to provide the facts. We need serious people to agree that this is a fixable problem, because it is.

The biggest challenge we face is the commitment of anti-plastic forces to stop the production of plastic — regardless of whether it is good for society or even the environment.

I really do wish we didn’t have to create our Recycling is Real initiative to show that recycling is happening every day across this country, but we did because those very activists would rather demonize the people who make the recycling process happen than work together to increase recycling rates. It really is frustrating that we spend so much time correcting the record. I’d rather spend more of my time and our organization’s resources working to make sure we support even more innovation and progress for our industry. I’m hopeful that will happen the more we see the acceptance that recycling is a key component of sustainability.

Matt Seaholm, president and CEO of the Plastics Industry Association.

Q: Last year under your leadership PLASTICS unveiled the Recycling is Real program. What is the objective of this program, how has it gone thus far and what are the plans to take these successes to the general public so that it gets a more balanced assessment of what is happening in the industry and the positive impacts it makes to their lives every day?

A: Recycling has come under attack from those who wish to reduce or eliminate the production of plastic altogether. Recycling is Real was created to put an end to false narratives claiming that recycling doesn’t happen or is a “myth.” The campaign shows how recycling happens, where it happens and introduces the people who make it happen.

Our target audience is policymakers at all levels because the first thing we need to do is stop the expansion of bad policies. We want them to know that recycling is happening, is important to our circular economy and can be done more frequently so they can make sound policy decisions that will meet our shared goals of reducing plastic waste.

We are happy with the early impact of this campaign, but we have a very long way to go to call it a success. This will be a long-term effort because we know the other side won’t change their tune and because there are so many examples of recycling across this country. Every few weeks, for as long as we can, you’ll see another story of recycling in America and the hardworking people making it happen.

Q: Relatedly, those that have dug their heels in against plastic tend to be well-organized, well-funded and backed by well-known people and companies. How can PLASTICS the association and plastics the industry respond meaningfully to those who contend the world would be a better place without plastics?

A: This is where my finance folks would say I should ask for money and no doubt, we need more resources. But the facts are on our side and that makes our message more effective to those who hear it, and most importantly want to listen to it.

I have had the opportunity to be around a lot of lawmakers at the state and federal level, and I truly believe the vast majority of them run for office and serve because they want to get things done. It’s those policymakers who are looking for real solutions that we need to work with. And it’s the other industries that rely on plastics or who are part of the recycling process that we must partner with. Building strong coalitions and delivering effective messaging is the way to overcome the well-funded activist groups and ensure that plastic continues to be an essential part of society — but we need to keep more of it in the economy and out of the environment.

As an industry, we are dedicated to eliminating plastic waste and preventing plastic waste from getting into the environment.

One thing is clear: completely eliminating plastics is not feasible nor economical. Plastics are essential. Plastics keep food fresh, protect health care workers from viruses, make cars more sustainable and help first responders during natural disasters. The plastics industry is the seventh-largest manufacturing industry in the United States and employs 1 million people, and contributes $548 billion to our economy; and when people are familiarized with the reach, impact and importance of our industry, they are reminded that we are part of their everyday lives.

Q: I believe that this is your first NPE. What tops your agenda planner?

A: This is my first NPE in this role, but I was lucky enough to have attended NPE2018. Two of the priorities for me in Orlando are making sure our exhibitors and attendees have a great experience and to make sure everyone who walks through those doors can see our industry’s commitment to sustainability.

We are working hard this year to give our exhibitors and sponsors the ability to tell their sustainability stories. NPE is the biggest showcase of all that our industry has to offer, and we need to seize the opportunity to advance our vision for sustainability as well as highlight what is possible in the world because of plastics. I can’t wait to officially open NPE2024 on May 6 and see the aisles fill up with people like me who are excited to see all the new innovations and technological advancements that haven’t been brought together like this in a long time.

We are working hard this year to give our exhibitors and sponsors the ability to tell their sustainability stories.

Q: There is a big emphasis on sustainability at the show, reflected not only in products that will be on display but in educational programs that are planned. As an industry, how do you think we are doing in this area?

A: Sustainability is a commitment that will be incorporated into every detail at NPE. The show will feature two sustainability and recycling zones where exhibitors will show their latest and greatest technologies. But we will also have a Sustainability Hub that will showcase the cool things happening throughout the entire plastic life cycle in an effort to highlight the importance of recycling and sustainability in the plastic industry.

There will also be an on-site recycling center which will serve as a live, interactive display for attendees to learn about the latest recycling techniques and as a place to recycle plastic scrap generated on the show floor. The goal for this NPE is to repurpose 100% of the plastic from the show.

We’ll also have an education stage dedicated to sustainability and how the plastics industry is finding ways to advance the circular economy.

Q: Of course, the NPE draws processors of all kinds as attendees. But there are lots of OEMs and brand owners that attend as well. Some might be under pressure to evaluate alternate materials for their applications. What do you hope these companies learn at the show?

A: Plastic is the best option and I guarantee at least one of our many exhibitors knows how to solve the challenge you’re facing. Whether it is complex performance needs, environmental footprint, safety or cost — NPE is where anyone who touches plastic in their manufacturing process can come to find solutions.

But I will reiterate — I want everyone who comes to NPE to recognize the commitment the industry has to sustainability. From energy consumption and lightweighting, to design for recyclability, to the prevention of preproduction plastic loss in the environment. We take this commitment to heart, and you will see it firsthand at NPE.

Related Content

Calculating an Injection Molding Machine’s Carbon Footprint

Arburg has utilized the ISO TS 1467:2018 standard, which determines the greenhouse gas emissions of a product, to help its customers calculate the product carbon footprint (PCF) of its injection molding machines.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

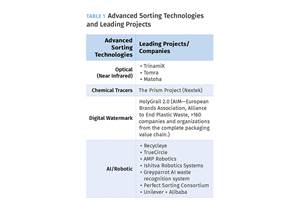

Read MoreRecycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreResins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)