Get Smart About Metal Detectors

Whether you are recycling plastic goods or processing virgin materials, producing a product free from metal contaminants is more important today than ever. Trends to thinner walls, tinier hot-runner nozzles, and more costly and sophisticated machinery and tooling mean that even the smallest piece of tramp metal can cause expensive problems.

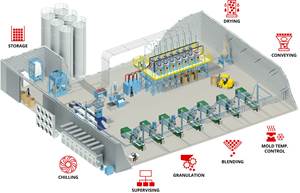

Processors often do not recognize the importance of metal-detection equipment. Even virgin material can acquire metal contaminants at various stages of manufacturing and transportation, right up until the moment it enters the throat of your molding or extrusion machine. Contamination can range from tiny particles worn off by equipment abrasion to entire nuts or bolts loosened by vibrations in processing machines. There's also the human factor: Inevitably, items such as coins, pens, and paper will occasionally fall into the product stream.

For this reason, metal-detection technology is used throughout the plastics industry to safeguard processing equipment and to ensure product purity. Metal detectors keep your product under strict surveillance at all times and prevent unnecessary machine downtime and costly maintenance.

When we speak of "metal detectors," some processors may think first of magnets. These are used effectively before the metal detector for capturing ferrous metals. Less familiar to many processors are electronic detectors for all types of metals. These are active devices that actuate a valve or other device to reject the contaminated material.

What's more, electronic metal detectors can be monitored remotely from a personal computer. This capability provides a record of where and how frequently contamination occurs in your plant. Such valuable data can help you compare the purity of different vendors' resins or diagnose excessive machine wear.

How metal detection works

There are two basic types of metal detectors:

Single-coil systems

When a metallic particle falls through the high-frequency electromagnetic field, an eddy current is induced in the particle, thereby removing energy from the coil system. As a result the maximum amplitude of the coil's vibration decreases. More energy is then supplied to increase the amplitude back to maximum level. This disturbance of the coil's vibration is detected by the electronic circuit as signaling the presence of a metallic particle.

Balanced-coil system

Single-coil systems provide cost-effective solutions for simple, "down-and-dirty" applications. These systems are easier to set up, but they cannot compensate for products that may be slightly conductive, owing to the presence of moisture, acidity, or additives like carbon black.

Balanced-coil systems offer product-effect compensation that suppresses false signals caused by the product. The benefit is to prevent rejecting perfectly good material. Analog versions require the operator to manually reset the compensation as material moisture content or other variable changes. Newer digital versions can be preset to self-adjust for different products or a range of moisture content or other variables within a product.

Making sense of sensitivity

Electronic metal detectors are high-tech, sensitive devices that must be handled with a certain amount of care. Excessive vibration from motors, chains, and other nearby equipment can cause a detector to emit a false signal and reject good material.

You shouldn't have to sacrifice good material for accurate detection and rejection. In addition to product-effect compensation, state-of-the-art metal-detection systems offer adjustable sensitivity and positive speed control to minimize the amount of material lost.

Maximum sensitivity of a detector determines the minimum size of metal particle that it can sense. Smaller particles can slip through, so this factor is crucial to selecting the proper detector for an application. Maximum sensitivity is measured by loading a sample of resin with steel spheres and taking the measurement in the middle of the coil, where the sensitivity is lowest. Steel spheres are used because they have a uniform, defined size, which means that the measurements are repeatable. Also spherical particles are the most difficult to detect because of their relatively low surface area.

All metal separators are not equally sensitive. True sensitivity depends on the size of the search coil. The smaller the search coil, the smaller the metallic particle that can be detected with maximum sensitivity. A good rule of thumb to keep in mind is that normal sensitivity is about 1% of the diameter of the coil. Depending upon the sensing aperture, innovative detectors are capable of detecting contaminants as small as 0.4 mm.

Sensitivity is also related to the composition and shape of the material. Although electronic all-metal separators will detect ferrous particles, stainless-steel, lead, aluminum, bronze, tin, and more, they are most sensitive to ferrous particles. That is because metallic particles are detected by means of eddy currents, and the higher the eddy current the higher the sensitivity. Eddy currents on the surface of ferrous particles are higher than those generated on the surfaces of aluminum, bronze, or copper particles, which means that the sensitivity of ferrous particles is higher than the latter. What's more, eddy currents from metallic particles are only effective on the surface, so the larger the surface, the higher the sensitivity. This means that flat metallic particles, or particles with irregular shapes, are much easier to detect than spheres.

Another feature offered by some metal detectors is called positive speed control. Because of differences in bulk density, metal particles may not travel through a pneumatic conveying line at the same speed as the resin itself. Positive speed control senses the actual conveying speed of the metal contaminants and automatically adjusts the open time of the rejection valve so as to eliminate the metal with a minimum of resin loss.

Different protection styles

The most versatile type is the free-fall metal detector, where the material is gravity fed through the inlet of the detector. Metallic particles are detected and immediately rejected by an air-operated rejection system. Adjustable sensitivity coupled with short rejection time ensures minimal loss of good product.

Free-fall units are available in single-coil or balanced-coil designs and with either analog or digital electronics. Free-fall units can range in aperture size from 25 to 300 mm (1 to 12 in.). Some types have a quick-clean rejection system that facilitates cleaning of the reject system.

Metal detectors for pneumatically conveyed materials take the form of a collar surrounding the conveying line. Again, these detectors are available in single- or balanced-coil design with analog or digital electronics. Positive speed control is available on some models to precisely time the reject-gate opening and closing in order to minimize the loss of good material.

Metal detectors for mechanical conveyors take the form of a tunnel surrounding the conveyor. This system can be combined with a variety of customized rejection options for loose or packaged materials.

Metal detectors for films and thin sheets use coils that are extremely sensitive at close range. They fit directly under the web and require very little space.

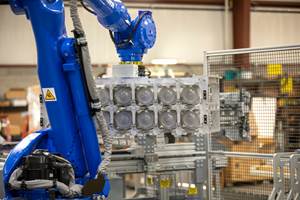

Separators for plug-flow applications are similar in operating principle to a free-fall detector. However, the plug-flow design detects metals in slow-moving or standing columns. A typical application is mounting the unit under the hopper and just above the throat of the processing machine. At Bunting Magnetics, we call this the "Last Chance Separator" or LCS. The LCS is built to support batch feeders, blenders, and other processing equipment weighing up to 250 lb. Equipment is bolted directly to the infeed of the LCS.

Add a magnet

Place a drawer, grate, hump, liquid-trap, or other magnetic separation unit upstream to work with your detector. Magnetic separators will pull all ferrous metal out before it reaches the detector. This will lighten the load of contaminants that pass through the detector, increasing its efficiency while minimizing the chances of rejecting good material. In addition, use of an upstream magnet allows you to adjust the detector's sensitivity to a higher level to catch only non-ferrous contaminants.

Ryan Entz is marketing supervisor and Jerry Hoffman is project manager for metal detectors at Bunting Magnetics Co. in Newton, Kan.

Related Content

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreAn Automation 'First' for Non-Servo-Eject Trim Presses

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreA Cost Saving Modular Approach to Resin Drying Automation

Whether implementing a moisture-sensing closed-loop system for a single dryer, or automating an entire plant, technology is available to take the guesswork and worry out of resin drying. Using a modular approach allows processors to start simple and build more capabilities over time.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More

.png;maxWidth=300;quality=90)