Global Packaging Giant Sets Sights on U.S.

Well established in other parts of the world, Greiner Packaging is bringing its wide array of food-packaging technologies to the U.S. market.

For Greiner Packaging, it wasn’t a matter of whether it was going to expand to the U.S., but when. This Austrian-based global packaging powerhouse did so in a big way by opening a 114,000 ft2 facility in October 2014 in Pittston Township, Pa. The plant, which can be expanded by another 114,000 ft2, enables Greiner to bring to the North American market a wide assortment of plastics packaging made by virtually every process. These include Greiner’s novel K3 (for Karton-Kunststoff- Kombination) container, a cardboard-plastic combination.

Now in its fifth generation of family ownership, Greiner’s roots extend as deep as 1868, when it started out as a cork maker. Some 160 years later, Greiner Packaging has more than 30 facilities in 19 countries around the world. These are primarily in Europe, where Greiner Packaging is widely recognized as a leading supplier of rigid plastics packaging, primarily for dairy products. But the firm recognized the opportunities offered by a footprint in North America: It first opened a plant in Mexico in 2010, and then the Pittston plant for its U.S. operation.

“We are one of the top suppliers of packaging solutions in Europe for decades,” notes Jörg Sabo, marketing director. “But as growth rates in Europe start to slow, it’s important that we look into expanding into new regions.”

Plastics Technology first toured the Greiner facility about two years ago. Greiner didn’t select the location on a random basis; company officials said central Pennsylvania was chosen because the region offers an excellent economic environment, qualified workers, and good transportation access to the U.S. market. At the time, the company said in a prepared statement, “We satisfy increasing needs for new and innovative packaging opportunities with our strategic step towards expansion. We therefore provide companies of the dairy industry a clear market edge. Moreover, many of our most important customers already have U.S. presence, so we can now continue to strengthen these good customer relations in the American market.”

Worldwide, the company employs about 4000. In 2015, its sales were roughly €561 million ($594 million U.S.) and are expected to be higher when Greiner Packaging closes the books on 2016.

Globally, Greiner Packaging brings to the marketplace capabilities in injection molding (with a particular emphasis on IML), sheet extrusion, thermoforming, blow molding, and more. Its product offerings are as vast as its global reach: hundreds and hundreds of different bottles, cans, lids, tubs, cups, closures, etc. Its biggest market is yogurt. Across its product line, Greiner Packaging has a strong emphasis on sustainability—what it calls Blue Packaging— and is producing products from both PLA and D-PET, which is a process developed by Octal in Oman (U.S. office in Plano, Tex.) in which PET sheet is produced directly from the reactor.

In Europe, plants are set up to replicate essentially the same technology platform, including production and decorating, says Sabo. Globally, manufacturing is supported by what Greiner calls DesPro, which is its Design and Prototyping team. Greiner has established innovation teams worldwide from several of its manufacturing plants that meet four to six times a year and ensure that developments originated in one facility are shared throughout the organization. Says Sabo, “We are very well connected internally for process, R&D, and new-product development.”

NEW U.S. CAPABILITIES

Greiner’s U.S. operation was originally focused primarily on K3, a PP-cardboard combination specified by Stoneyfield Farms and others for yogurt. The idea behind the K3 package is to combine the feel of cardboard with the functionality of plastic, notes David Kirkland, a 13-year Greiner Packaging veteran who took over as president of the U.S. operation in January. The combination of the two materials gives the package more topload strength than an all-plastic container, and greater shelf life than an all-cardboard structure.

The cardboard package is designed with a zipper so that it can be easily peeled off and separated from the plastic cup inside. It also reportedly permits a 50% reduction in resin vs. an all-plastic cup.

Kirkland reports that the K3 container has been well-accepted in the U.S. market and that business has increased quarter-to- quarter since the Pennsylvania plant opened. But realizing that K3 might not be the solution for every application, Greiner Packaging is exploring options and expanding its technology portfolio in Pennsylvania. Currently it is examining HDPE as an alternative to PP for its innovative cup, owing to the fact that HDPE is more readily available and more well-established from a recycling point of view. HDPE-based K3 containers are in their initial testing phase.

Greiner Packaging has also upgraded its dry-offset printing capabilities with a proprietary process it calls Ultra Brilliance that the company says achieves higher resolution and an improved color gradient. The end result is an image with “near photo” quality. It also offers laser-engraved printing plates that it says are more environmentally friendly than decorating techniques that rely on chemicals.

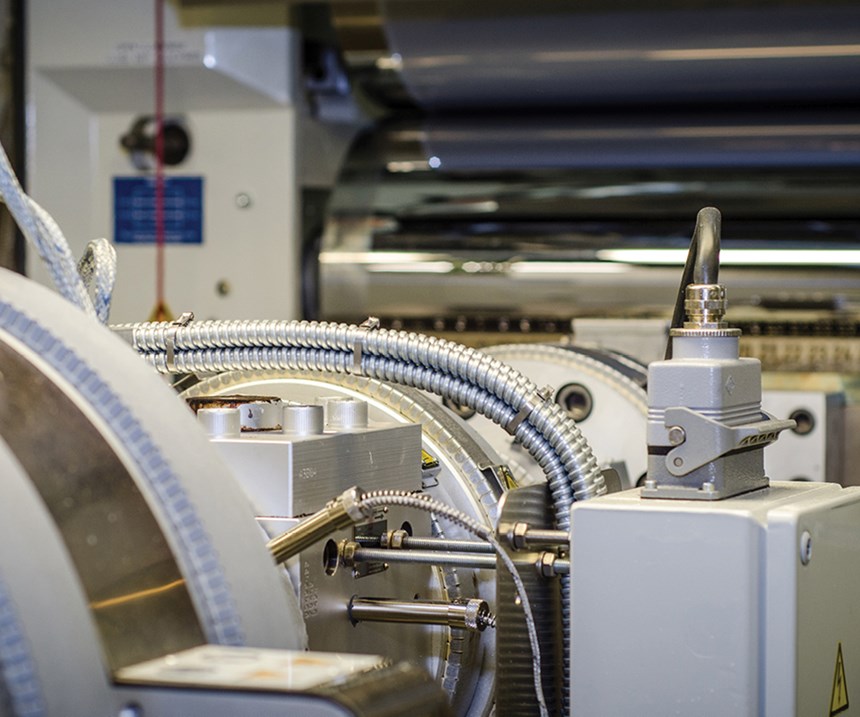

Greiner Packaging started in Pittston Township with sheet extrusion and thermoforming capabilities. Since then, it has added injection molding capacity with in-mold labeling.

Greiner’s Pittston Township plant is pristine. There is no piping for utilities on the production floor. Instead, services are located in separate rooms. Material is fed from three silos outside to blenders situated on a mezzanine above the production floor. Post-forming skeleton scrap goes to a granulator and is automatically refed into the production process.

After forming, the containers are sent to a cup-cardboad assembly machine Greiner Packaging jointly developed with a German company. Instead of wrapping the cardboard around the cup, the machine first creates the cardboard wrap, then the formed plastic cup is placed inside. As a result of this approach, only one dot of adhesive is required to join the two components. Cups are stored for 24 to 48 hr in a temperature-controlled room to account for shrinkage. In the U.S., Greiner Packaging currently supplies cups in 73-, 80-, 95-, and 116-mm diam.

On the factory floor, a quality-control lab is fully instrumented to check products for height, width, topload strength, dimensions, etc. In Europe, Berglandmilch of Austria, a supplier of milk, butter, cheese, and other dairy products, opted for a rectangular K3 package and won a Save Food Award from the national Czech competition, Obal Roku. (This technology is not yet available in the U.S.) The Save Food Award is a prize awarded to particularly sustainable solutions and technologies.

Greiner Packaging currently employs about 60 in Pennsylvania; but with an eye toward expansion, the firm has developed a program that it hopes will attract new talent. This Greiner Gold Program combines an Associate’s degree and on-the-job training for a total of three years. The packaging processor offers the state-recognized program in conjunction with Luzerne County Community College in Nanticoke, Pa.

Students are mentored by selected Greiner Packaging employees throughout the Gold Program, and their progress is reviewed by Greiner’s program coordinator, Kirkland explains. At the plant, mentors are constantly available to provide training and support in each technical area to ensure students get the best possible experience.

Says Kirkland, “Our plan is to bring technology we utilize around the world to re-invent the business of providing high-end premium packaging.”

Related Content

In-Mold Labeling Adjustment Head

Beck Automation says the new adjustment head targets production of small medical consumables packaging.

Read MoreKurz Opens New Plant in Vietnam

The maker of decorative thin films invested 37 million euros in the new 60,000-m2 plant in Quy Nhơn, which joins regional production facilities in China and Malaysia.

Read MoreDuraTech Industries Licenses TactoTek’s Injection Molded Structural Electronics (IMSE)

The custom graphics manufacturer specializing in in-mold and printed electronics now has the rights to sell, design and produce parts that use TactoTek’s intellectual property.

Read MoreBorealis and Bockatech Showcasing Ultra-Lightweight Reusable PP Cups

Use of Borealis PP and Bockatech’s EconCore next-generation foaming technology yields thin-wall, robust and fully recyclable cups.

Read MoreRead Next

Global Processors Establishing U.S. Footprint

Two major international processors establish plants in central Pennsylvania to serve the U.S. market.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

.png;maxWidth=300;quality=90)