Plastics Use in the Packaging Industry

Plastics are used to manufacture flexible packaging and rigid packaging in applications like caps, closures, bottles, film, and sheet.

ESSENTIAL READING

VIEW ALLBack to Basics: Tandem Foam Sheet Extrusion

This complex process requires precise equipment and process expertise to produce high-quality sheet. Here’s what you need to know to get started.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

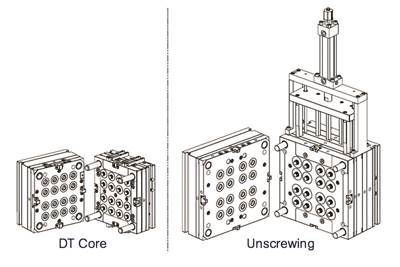

Read MoreBest Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

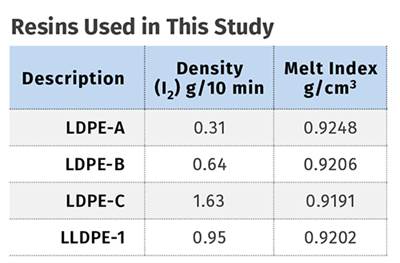

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreProtolabs Addresses How to Survive a Pandemic with Digital Manufacturing

Protolabs survey results examine product development and the supply chain.

Read MoreLatest Packaging News And Updates

All-in-One ISBM Machine for Hot-Fill, Returnable/Refillable PET Bottles

At K 2025, Nissei ASB shows off its first 1.5-step machine for PET bottles with preform injection, double-blowing and heat-setting.

Read MoreAll-Electric Coex Machine for Ultra-Clean L-Ring Drums

K 2025 is the world premiere of a new three-layer machine from ST BlowMoulding for specialty L-ring drums.

Read MoreK 2025: New Hybrid ISBM Machine Offers Upgrades for HDPE Bottles

Nissei ASB introduces hybrid version of ASB 70DPH machine that offers greater productivity and design freedom for HDPE bottles.

Read MorePET Bottle Design Combines Super Light Weight With Premium Aesthetics

KHS adopts a “premium lightweight approach” with its new 0.25-L KHS Premium Lite PET bottle for still water.

Read MoreDow Announces Alternative to Fluoropolymer Polymer Processing Aids

Dowsil 5-1050 PPA for film packaging.

Read MoreCosmetics Compact Case Demonstrates Molecular Recycled PET

Toly is Eastman's first partner to apply this material in compact packaging.

Read MoreFeatured Posts

Back to Basics: Tandem Foam Sheet Extrusion

This complex process requires precise equipment and process expertise to produce high-quality sheet. Here’s what you need to know to get started.

Read MoreInjection Blow Molder Reduces Maintenance, Power Consumption

Amcor applied Cito’s PulseCooling to reduce leaks and power consumption on its production floor while boosting output and accuracy.

Read MoreRunning PET Flake? Here's How a Crystallizer Can Help

Crystallizers were designed and manufactured by many auxiliary equipment manufacturers in the 1970s with the mistaken belief that packaging-grade virgin PET would eventually become available to processors in amorphous, rather than crystalline pellet form.

Read MoreIt’s No Stretch: MDO Technology Revolutionizing High-End Film Packaging Business

Machine direction orientation combined with new resin technology helps film processors develop simpler, more readily recyclable monomaterials to meet sustainability demand.

Read MoreBlow Molder Packs Sustainability Into Every Container

With back-to-back EcoVadis platinum recognitions, Ring Container Technologies is a sustainability frontrunner. PT toured the company’s Fontana, California, blow molding facility to see what it takes to be an eco-conscious producer of plastics packaging.

Read MoreInjection Foaming Tech Reduces Density, Increases Mechanical Properties

Based on an additive package custom-tailored to the application, Moxietec’s foaming technology promises stronger parts through consistent bubbles.

WatchFAQ: Packaging

The following are four other common issues, applicable to both single- and two-stage processes.

-

Pearlescence and haze

-

Insufficient top-load strength

-

Insufficient base clearance or rocker bottom

-

Drop-impact failure