Headlines from Fakuma 2018

Integrating a special low-pressure process into machine controls; novel shop-floor quality-inspection technology; MES systems from machine and controls vendors; and sophisticated in-mold decorating.

With 1933 exhibitors from 40 countries, the Fakuma 2018 show in Friedrichshafen, Germany, attracted 47,650 visitors over five days in October. Though still overwhelmingly oriented toward injection molding, the show was notable for the higher profile of materials suppliers and for the first-time presentation of an Extrusion hall. Fakuma occurs annually but skips every third year when the K Show takes place in Dusseldorf. As compared with the much bigger and more hectic K Show, Fakuma is praised by exhibitors and visitors alike as a more relaxed setting for discussing plans and projects.

Fakuma was loaded with news—much more than one article can present; so the following is a brief selection of some major introductions and themes at the show. (See also Fakuma news announcements in Starting Up and Keeping Up sections this month an in our August through November issues.)

MILACRON INTEGRATES iMFLUX PROCESS

As previously reported in an October Starting Up, Milacron announced—and demonstrated live—a first-of-its-kind agreement with iMFLUX, the new subsidiary of Procter & Gamble that developed a novel injection molding concept based on low and highly consistent injection pressure. Through this agreement, Milacron will integrate iMFLUX’s proprietary process-control software into its injection machines with a native user interface and screens on its Mosaic controller. Milacron will be the first machine manufacturer to offer such integration, which eliminates the need for a separate iMFLUX control screen.

iMFLUX uses low but highly consistent pressure, allowing velocity to vary with the geometry of the part, to achieve up to 50% faster cycles with reduced part weight, lower stress, less warpage, and fewer sinks, as explained in a March ’18 feature article. Outfitting a machine for iMFLUX typically requires a nozzle adapter with a pressure sensor, a CPU in the control cabinet to send signals to the machine controller, and special control software. Company sources say the process has been tested on machines from 20 to 5500 tons and on molds with up to 196 cavities. Although iMFLUX offers relatively little speed advantage in very fast-cycle molding, it reportedly still offers quality benefits through improved balancing of high-cavitation molds. For that reason, the company is exploring cap and closure applications. iMFLUX has also done some experiments with the process in co-injection and gas-assist molding.

At Fakuma, iMFLUX showed a new enhancement in the form of automatic viscosity-adjustment software. It recognizes a change in melt viscosity and adjusts filling to maintain consistent low pressure. At the show, this capability was demonstrated by switching on the fly from molding a 20 MFI PP to 8 MI PE and vice versa. In real life, iMFLUX sees this capability as assisting in the use of scrap or recycled materials, whose viscosity can be variable, especially when the proportion of reused materials may vary over time. (See October PT blog for more details.)

RAPID INSPECTION OF PARTS’ INTERNAL FEATURES

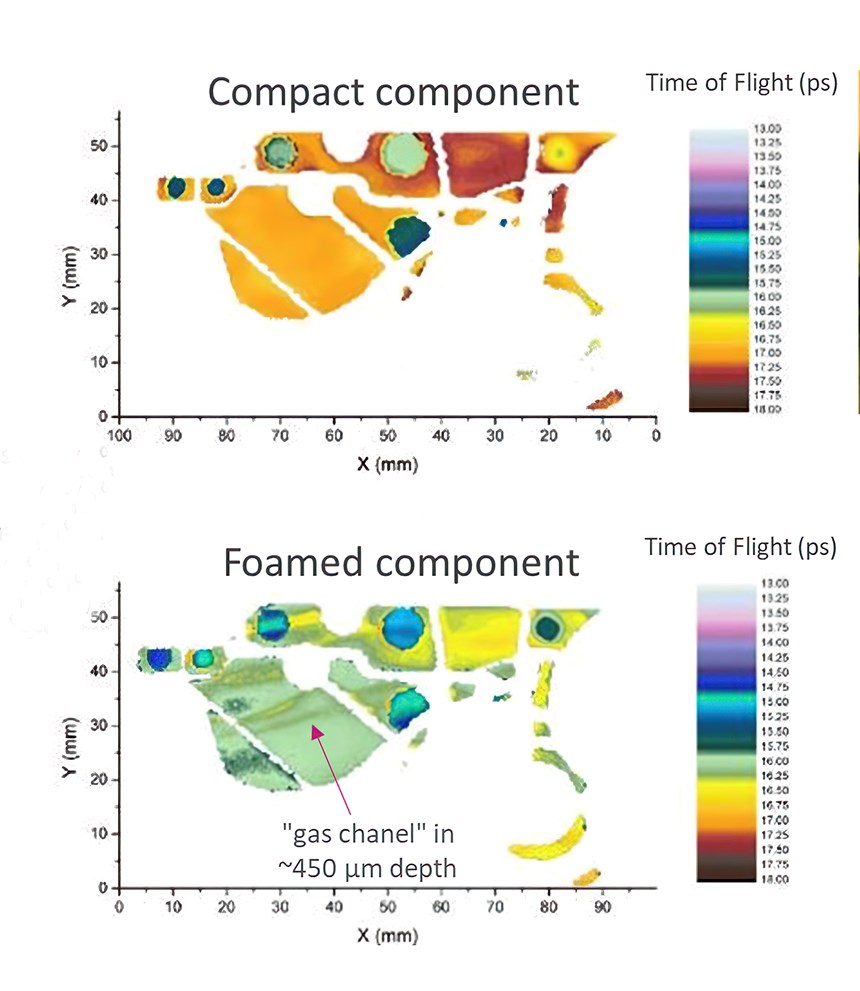

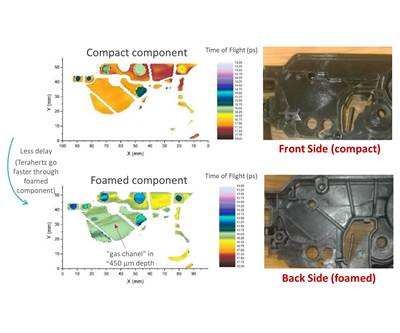

A new noncontact, nondestructive, and nonhazardous technique can perform dimensional QC and look inside plastic parts for voids, foreign bodies, foam structure, glass content and glass orientation in as little as 30 sec. New TrexelVision system offers a way to perform immediate shop-floor inspection and QC without sending parts to the lab. It allows you to “see the invisible” inside solid or foamed parts either in-line or off-line.

TrexelVision is the result of an exclusive distribution agreement that allows Trexel, the source of MuCell microcellular molding technology, to offer the STRIPP Control IM technology for injection molded parts from TeraTonics of France. STRIPP stands for Single Shot Terahertz Sensing for Rapid Industrial Product & Process Control. It employs the technique of terahertz (THz) spectroscopy, a method involving ultra-short pulses (measured in picoseconds, or 0.001 nanosecond) of electromagnetic radiation in the submillimeter wavelength range, in between microwaves and infrared light. TrexelVision integrates a broadband source and detection system for the 0.1 to 1 THz spectral range, as well as an industrial control and data-acquisition unit with proprietary software for scan motion and data processing. It allows for robotic scanning of 3D objects based on their CAD files—beside an injection press, for instance.

STRIPP has been used to measure the thickness of multilayer coatings, to inspect composites, and to measure glue layers in assemblies of composite parts. For injection molding, it can perform wall-thickness measurements to ±3 microns. In foamed parts it could measure the thickness of the solid skin vs. the foamed core. It can also determine the density and uniformity of the foam cell structure; find voids or bubbles in solid parts; reveal foreign-body inclusions, internal weld lines, or the quantity and orientation of fiber reinforcements; and even show the boundaries between materials in multi-component parts. Another fascinating capability is to “slice” the part into virtual layers, revealing internal structure at different depths, as in medical tomography (CT) scans. (See October blog for more details.)

In addition, Trexel rolled out a new system that allows molders to operate multiple presses running the same parts with MuCell foaming off a single gas booster unit. This cost-saving approach involves a new satellite dosing unit that can be fed by Trexel’s T-Series or new P-Series boosters (the latter for fast-cycle packaging), its B-Series for blow molding, or a non-Trexel pressure source. Also new from Trexel are T-Series central gas boosters based on T300 and T400 compressors to feed satellite units.

MORE SUPPLIERS ADD MES SOFTWARE

Major injection machine suppliers have indicated that MES (manufacturing execution systems) are essential components of their Industry 4.0 strategies. Several of these OEMs offer their own MES products, have purchased MES software vendors, or formed alliances with such vendors.

Among the latest developments, Wittmann Battenfeld has purchased a stake in Italian software firm ICE-flex and is now offering a version of that company’s TEMI modular MES package. Called TEMI+, this version is tailored to work with Wittmann 4.0 production cells and provide special functionality made possible by Wittmann 4.0 router technology. In particular, TEMI+ connects automatically with Wittmann Battenfeld presses and Wittmann auxiliaries—whether or not those auxiliaries are connected directly with the injection machine. Any alterations in the composition of the production cell—such as connecting different auxiliaries when changing jobs—is recognized, saved and displayed automatically by TEMI+. This capability is said to be unique to TEMI+, as is the ability to display on a computer or mobile device a dashboard of Key Performance Indicators (KPIs) of all connected equipment in the cell. This dashboard offers OEE for the machine and entire cell.

Wittmann Battenfeld says TEMI+ offers a simple approach to entry-level MES data collection. Modules include ERP connection, production planner, “alarm messenger” specifying time and cause of stoppages, QMS module that records process data and stores quality-inspection instructions, and a production monitor that displays all machines’ status at a glance.

Wittmann Battenfeld USA anticipates that it may be three to six months before TEMI+ is launched in this hemisphere.

Meanwhile, Engel’s wholly owned MES provider, Austrian-based TIG, is establishing a U.S. subsidiary in York, Pa., home to Engel’s North American headquarters. It will open next month. TIG announced several modifications to its product line. One is a new “rental” or subscription model for its authentig standard MES package. Another is a new entry-level package, called TIG 2go, also on a subscription basis. It requires installation of a data-acquisition box on each machine—or one device can collect data from up to 20 machines—to send data to the cloud. Users have access to an online dashboard showing machine operating status in one or multiple plants, OEE performance data, SPC figures, and historical data for up to six months. Cost is $1/day per machine, not including the data device.

At the other end of the scale, TIG big data is an open system for connecting all machine and plant sensors, ERP, MES, and other business software platforms, along with custom analytics. High-volume data storage can be local on company servers or in the cloud.

As a sign of spreading interest in MES, Kistler Group, the Swiss-based maker of sensors, monitors, and controls for injection molding, has taken a further step into Industry 4.0 solutions with the acquisition of IOS GmbH in Aachen, Germany, which develops modular MES software.

Kistler’s MES offers automatic data acquisition from injection machines via the machine controls or, for older machines, via a web-connected mini-PLC installed on the machine. Kistler offers a full system as well as an “MES Light” version designed as an entry-level product that allows users to get started quickly with minimal setup. At present, this option includes two pre-configured modules for data acquisition:

• Machine data—cycle times, machine status, good/bad parts production quantities.

• Operation data—transfer of production orders directly from an ERP system, starting and stopping of jobs, recording reject reasons, and calculating OEE (overall equipment efficiency).

Kistler also offers a full-blown MES system with the foregoing two modules plus modules for batch traceability, maintenance management, production planning, and workstation-based staff-time logging.

IMD ON A ROLL

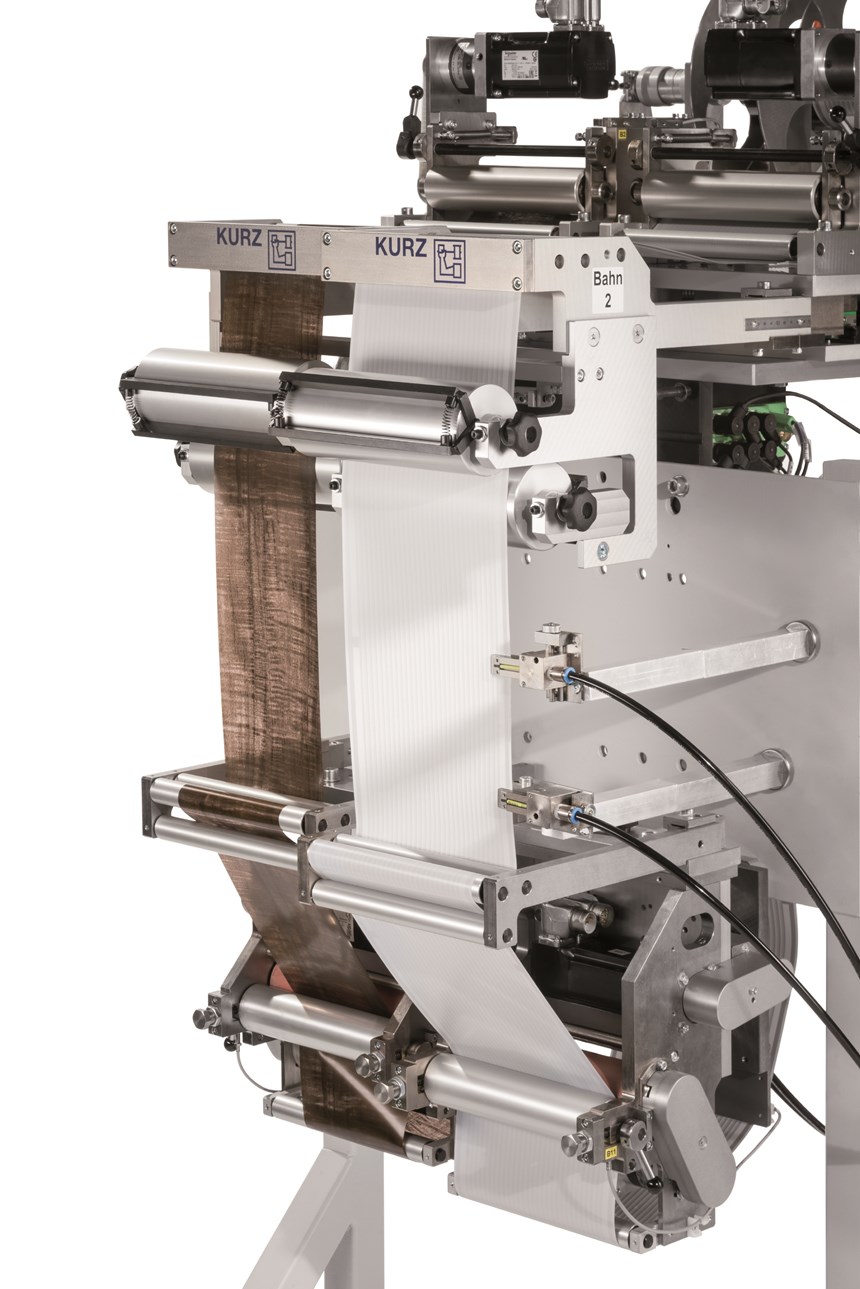

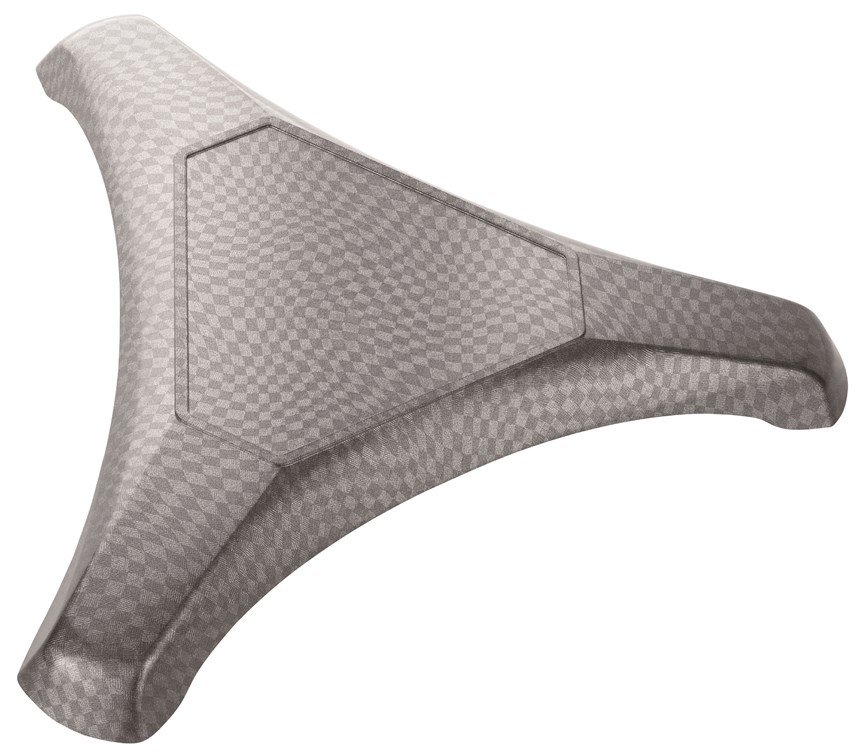

While in-mold labeling (IML) for packaging has become ubiquitous at major trade shows, Fakuma this year was notable for high visibility of the related technology of in-mold decorating (IMD), aimed largely at automotive, appliances, and consumer electronics. As distinguished from IML, IMD for durable goods frequently involves roll-to-roll feeding of decorative and functional surfacing materials for back molding; paint films on a carrier film, which are deposited via back molding; or functional electronics (e.g., touch sensors) that can be applied in the mold like IML or bonded to the part after molding via vertical or roll-on hot-stamping.

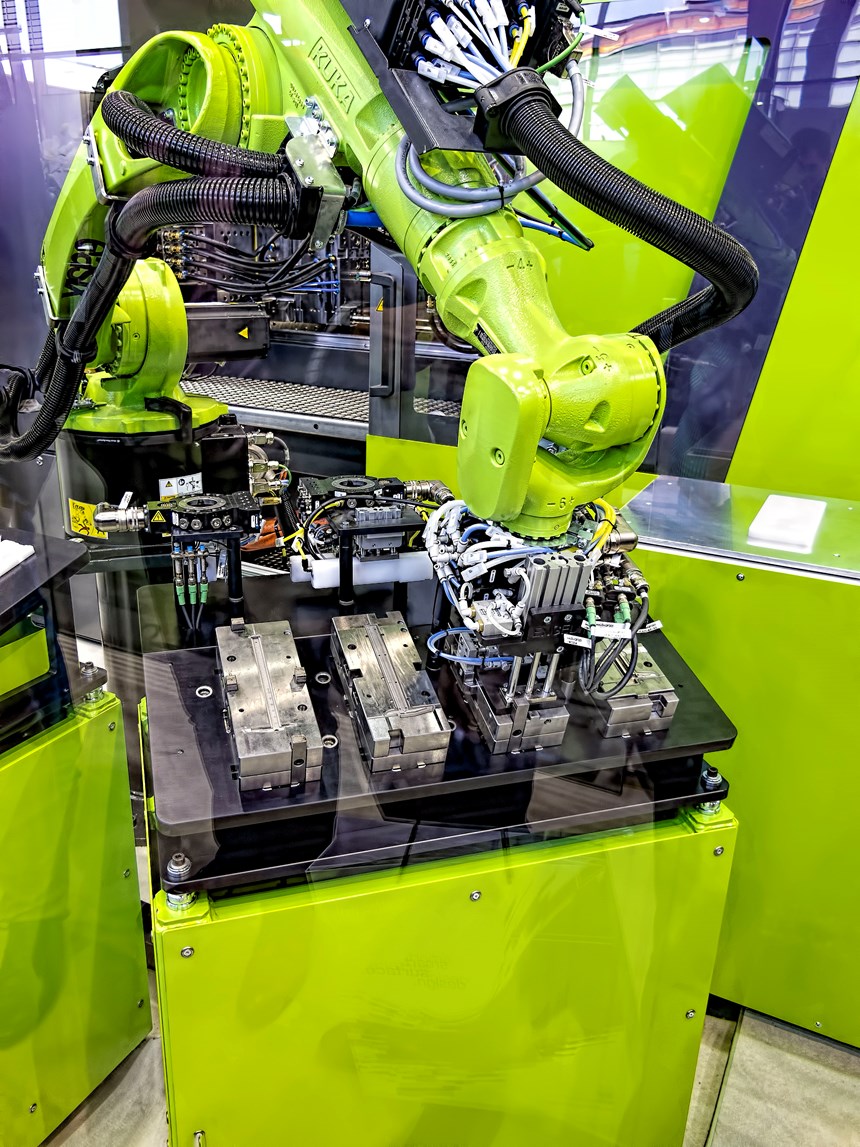

At Fakuma, three injection machine suppliers demonstrated varieties of IMD, all in cooperation with IMD specialist Leonhard Kurz (parent of Kurz Transfer Products in the U.S.). Engel, for example, showed off a roll-to-roll system for vacuum forming, back-injecting, and punching out diverse surface structures within the mold. This demo showed off Kurz’s new single-step “IMD Varioform” foils and topcoats that accommodate complex 3D shapes—something not available previously, according to Kurz. Foil preheating may be required in some cases. Possibilities include metalized (brushed or chrome) surfaces; wood, marble, or carbon-fiber look; single-image designs; partial and full-surface backlit designs; and tactile qualities from smooth surfaces to distinctive structures or soft-touch effects.

As reported in September Starting Up, KraussMaffei operated a cell demonstrating Kurz’s patented dual-IMD technology that allows two independent heat-transfer foils to index through a two-cavity mold with the aid of servo motors and optical sensors to detect registration marks on the foil. This reportedly allows, for the first time, deposition of two single-image designs with precise positioning. At Fakuma, dual IMD was supplemented by IML in the same cycle to produce an automotive HMI display with integrated electronics, black decorative frame, and scratch-proof coating (UV cured outside the mold).

And Sumitomo (SHI) Demag demonstrated two decorating steps in production of an automotive door sill with day/night design and touch-activated backlighting. Kurz’s day/night decoration was applied in the mold via IMD. Then, in a post-molding operation at Kurz’s booth, the same parts were hot-stamped with transparent touch sensors having silver-based printed circuitry on a PET carrier and an integrated plug. Kurz calls this Functional Foil Bonding (FFB). Its elastic PolyTC sensors (produced by Kurz subsidiary PolyIC) can be integrated into fashionably curved components. In addition, a laser marking station applied a QR barcode so that production data from the Sumitomo Demag cell could be uploaded to an MES computer.

Related Content

Honda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.

Read MoreNew Technology Bonds Aluminum With Polyamides

With many benefits for numerous potential applications, including in the burgeoning electric vehicle market, Celanese’s Zytel Bonding Technology achieves stronger bonds than overmolding or welding.

Read MorePlastic Compounding Market to Outpace Metal & Alloy Market Growth

Study shows the plastic compounding process is being used to boost electrical properties and UV resistance while custom compounding is increasingly being used to achieve high-performance in plastic-based goods.

Read MoreDesign Optimization Software Finds Weight-Saving Solutions Outside the Traditional Realm

Resin supplier Celanese turned to startup Rafinex and its Möbius software to optimize the design for an engine bracket, ultimately reducing weight by 25% while maintaining mechanical performance and function.

Read MoreRead Next

Milacron Demonstrates iMFLUX Low-Pressure Injection Molding at Fakuma Show

Milacron is first to demonstrate this innovative low-pressure process at a trade show.

Read MoreNon-Destructive, Non-Hazardous Approach to Rapid Internal Inspection of Molded Parts

Terahertz spectroscopy allows in-line or off-line inspection of not only dimensions such as wall thickness, but also internal structure of solid or foamed parts.

Read MoreMilacron Is First to Integrate iMFLUX into Machine Controller

Integrating iMFLUX low-pressure process into machine controls is a more economical route to faster cycles and improved part quality.

Read More