Brothers Mike and Dave Skaggs have worked in plastics for their entire careers, beginning at the St. Louis injection molder where their father started working in 1961 and eventually became its president. Upon his passing, they knew a big change was at hand.

“That company was where we got our education and our start,” Mike Skaggs says. “When our dad passed away, it was pretty much within 24 hours that we knew something was going to change. We didn’t know what; we had no idea it was going to be this.”

“This” is MDS Manufacturing LLC, the St. Louis-based injection molding company Mike and Dave founded in 2010 with three presses and four employees. Customers who had worked with the Skaggs family at the former molder, helped pushed Mike and Dave to found MDS.

“Within a week or so, we were approached by some of our long-time customers, and they said, ‘Hey look, if you and your brother ever think about starting your own company, we’d definitely come with you,’” Mike says. “I told my brother about that conversation, and we kind of looked at each other like, ‘Well, if we don’t give it a shot now, we never will.’”

MDS was founded on thermoplastic injection molding, and that business has the company looking for a larger site and planning to add higher-tonnage presses. (Photos: MDS Manufacturing)

It was one of those customers that triggered the next two major changes at MDS—its rapid entrance and, eventually, near-total exit from molding liquid silicone rubber (LSR). The client—a baby-products company—was looking to shift sourcing of nipples stateside and approached MDS about this “reshoring” opportunity in 2013. “We bought one machine; they gave us a mold; we figured it out, and from there it went to seven machines and 10 molds.” At the same time, MDS got into injection stretch-blow molding (ISBM) of PP baby bottles for the same customer.

In short order, MDS was running LSR 24/7 and molding 1 million silicone parts/month, ramping up rapidly. “It was a very short period of time,” Mike says, pausing before adding with a wry laugh, “and it disappeared in about as short a time.”

In 2019, after a change in management and strategy, the baby-products customer pulled all its LSR parts and molds from MDS, removing 99% of MDS’s silicone business effectively overnight. By January 2016, MDS had grown to 18 machines—including seven LSR presses—and 30 employees. Since the LSR business was pulled, MDS has sold two LSR machines and had another two lined up for sale when pandemic-induced LSR material shortages forced that buyer to back out. MDS still has some LSR business, including a soda-dispenser component, but the sudden change pushed it to reevaluate its overall strategy.

“I can remember telling my brother, ‘We’ve just got to keep chipping away,’” Mike says. “That’s what we did. We went back to the ‘old school’ and picked up the phone. It doesn’t really matter what size of customer it was. We like to help out the smaller guys because we were, and still are, one ourselves.”

Back in 2010, MDS started with three Nissei injection molding machines and four employees.

Constant Change

Today, MDS has 30 employees and seven thermoplastic injection molding machines ranging from 80 to 500 tons, including presses from Welltec, HPM and Nissei. It still has five Engel LSR machines, but apart from some stray jobs, they’re mostly mothballed. While the LSR nipple business is gone, MDS still injection stretch-blow molds PP bottles for the baby-products customer on three Aoki machines. Running 100,000 bottles/week, MDS molds 2-, 4- and 8-oz versions, in addition to injection molding some bottle components for the former LSR client.

We like to help out the smaller guys because we were, and still are, one ourselves.

Occupying 23,000 ft2, the company is seeking to expand and is negotiating for a new 50,000-ft2 site in St. Louis, situated on an acreage with further room to grow. MDS would use the space to grow its secondary operations, which currently involve assembly (including sonic and spin welding), hot stamping, pad printing and custom packaging, while also creating room for a bigger press, (above 750 tons)—heralding still more changes for the company ahead.

“We’ve always talked about expanding, but we’re just trying to decide how big do we want to go. We have ramped up our efforts in the last six months,” Mike says, gesturing at the stacks of boxes around the conference table and surrounding the largely idled LSR machines in the next room.

Brothers Mike (right) and Dave Skaggs learned injection molding alongside their father and set off to launch their own company after his passing.

Photo Credit: MDS Manufacturing

True to Its Roots

Change enough and a company can get so far removed from its initial origins, that it forgets what it’s all about and why it got started in the first place. Despite the myriad changes MDS and the Skaggs brothers have experienced over the last decade, they never strayed far from their roots.

“MDS actually stands for my dad’s initials,” Mike says, displaying a business card. On the back, it reads, “In Honor of Marvin D. Skaggs,” accompanied by the father’s signature. “That’s my dad up there in black and white, as he started in 1961,” Mike says, indicating a picture of Marvin on the office wall. “We all just went into it.”

I still quote every job with a piece of paper and a pen. I don’t have any fancy formulas.

LSR molding was a departure from what the Skaggs had known, but it helped MDS grow in its early years, and Mike says the company is still quoting and pursuing jobs in the material.

“It was almost a blessing that we weren’t that deep into it,” Mike says, remembering a lesson his father passed on to him and his brother. “That was one thing that we were taught at a very young age by our dad: ‘Don’t get pigeon-holed into one industry.’” Today, the plant produces parts as diverse as a fuel cap, hockey face mask and a farm-equipment equipment housing.

Even as LSR showed explosive growth, MDS kept growing its traditional thermoplastic business alongside it, which helped it withstand the blow when LSR orders almost entirely vanished. “Any losses we may have incurred from the LSR, we’ve made up for in regular molding,” Mike says.

MDS fulfills weekly orders for injection stretch-blow molded baby bottles, formed on three Aoki machines.

Old-School Molding

“MDS is a simple story,” Mike says. “We’re kind of an old-school type thing.” When the company looked to fill the LSR hole in its business, Mike and Dave worked the phones and used some other Industry 3.0 tools. “I still quote every job with a piece of paper and a pen. I don’t have any fancy formulas. We believe in long-term customers vs. short-term guys.” In fact, Mike says all of the clients that initially pushed them to start MDS back in 2010 are still ordering parts. “The customers we started with and have brought in are all still here,” Mike says.

Just as Mike and Dave learned from their father, now a new generation of Skaggs are learning the molding business, including Dave’s daughter and Mike’s son. “So there is a next generation that hopefully will carry it on,” Mike says. “If we’ve made it through a pandemic, and an economic downturn, and I don’t know what else they can throw at us, we can survive.”

MDS’ three Aoki ISBM machines stay busy blow molding three sizes of PP baby bottles.

Related Content

Beacon MedTech Solutions Names New President

The Massachusetts-based medical molder and contract manufacturer has appointed industry veteran Jim Colony.

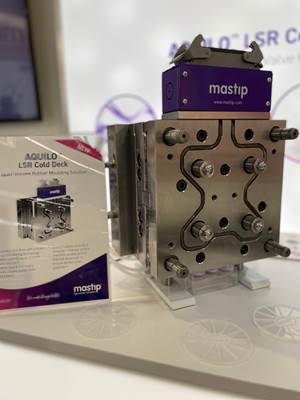

Read MoreNew LSR Cold Deck

Hot runner supplier Mastip used K 2022 to introduce the customized and valve-gated Aquilo liquid silicone rubber (LSR) cold deck.

Read MoreCustom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.

Read MoreSlimmer All-Electric Press Debuts

A slimmed-down version of Engel’s all-electric, e-mac injection molding machine is among eight displays, which also include LSR micromolding, quick mold changes and a cube mold.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

.png;maxWidth=300;quality=90)