How Life Cycle Assessment (LCA) Measures a Manufacturer’s Carbon Footprint and Environmental Impact

Life cycle assessments (LCA) are rising in popularity in some industries as a way of evaluating a product’s environmental impact. What are LCAs and what do they mean for Tier suppliers?

Life cycle assessments (LCA) are one tool OEMs, fabricators and suppliers can use to understand — and improve — the environmental impact of composite parts and materials. Source: Getty Images/Avient

As manufacturers work toward requirements for reduced carbon emissions and overall environmental impact, many of these goals are likely to have ripple effects down the supply chain.

For example, a first step for many OEMs is to evaluate the current environmental impacts of their products through increasingly prevalent life cycle assessment (LCA) studies, which can help inform decisions about how to choose more sustainable materials and processes for a particular product, or to show what areas of a process might need improvement.

In the process, Tier suppliers are increasingly asked by OEMs to report their own data related to carbon footprint, water usage and other environmental impacts.

What is an LCA and how can Tier suppliers prepare themselves to meet this need?

What is an LCA?

Life cycle assessment (also called life cycle analysis) is a process for evaluating the environmental impact in multiple categories — resource depletion, water, global warming potential (GWP) and more— of a product from raw materials and manufacture through to disposal at the end of its usable life.

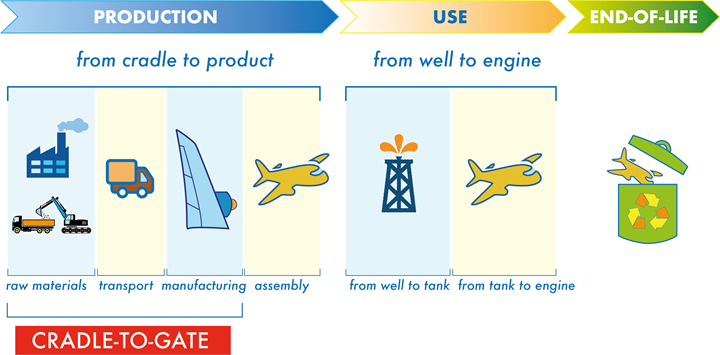

A cradle-to-gate or partial LCA (commonly performed by Tier suppliers) assesses impacts from the production of a product’s raw materials through manufacturing of the part, ending at the point the product is ready for use by the consumer; a cradle-to-grave or complete LCA (commonly performed by OEMs) assesses the product through its use and eventual disposal at its end of life (EOL).

Either way, the goal is to quantify the carbon emissions of each step of the supply and value chain for a given product or process. Generally speaking, emissions are labeled by their scope. Scope 1 emissions are direct greenhouse gas emissions, such as those associated with fuel-burning facility equipment like furnaces or boilers, or by gas-powered vehicles. Scope 2 emissions are indirect greenhouse gas (GHG) emissions used by the company, such as those associated with electricity or heat for the facility. Scope 3 emissions are also indirect emissions, but those that result from assets not directly controlled by the company in question — including everything from production of raw materials, transportation and distribution, and any other emissions not covered by Scope 1 and 2.

A cradle-to-grave LCA evaluates a part’s environmental impact through production, use and end of life, while a cradle-to-gate LCA covers impact through manufacturing. There are a variety of software available to help companies through the LCA process, including the European Composites Industry Association’s (EuCIA) Eco Impact Calculator. Source: European Composites Industry Association

LCA Guidelines, Standards

How are LCAs performed? While there is no global standard for conducting LCAs to date, there are several guidelines available with varying degrees of complexity and specificity, and for various regions. For example, ISO standards are widely used, primarily 14040 and 14044 — the former provides “principles and framework” and the latter provides “requirements and guidelines.”

There are also a variety of other LCA guidelines for specific industries (such as ISO 22526 for biobased plastics) and specific regions (like Japan’s EcoLeaf program, the European Commission’s International Reference Life Cycle Data System (ILCD) and proposed Product Environmental Footprint (PEF), currently under review.)

While specific LCA methodologies differ, in general these studies are set up with more or less three components:

- A section defining the goals, scope and units used in the LCA;

- A life cycle inventory (LCI) which quantifies the carbon footprint of input materials as well as output emissions and waste

- An impact assessment which translates the LCI into a measurable climate impact. Per ISO 14040, for example, these final impacts are given in terms of GWP or carbon dioxide equivalent (CO2e).

The Rising Demand for LCAs

So why are companies interested in LCAs now? First conducted in the 1960s, LCAs have waxed and waned in popularity over time depending on the concerns of the day. Today, OEMs are facing greater demand for transparency into the “sustainability” of their products, spurred by environmentally conscious consumers as well as proposed legislation like the EU’s PEF guidelines.

For Tier suppliers, this means customers may be looking for data into process or materials operations. Markus Beer, group lead sustainability at automotive consultant firm Forward Engineering GmbH (Munich, Germany), explains that OEMs conducting LCAs need Scope 3 emissions data, which they obtain from gathering carbon emissions information from their own Tier manufacturers and suppliers downstream.

He adds that, in addition to working with customers, “Some Tier 1s and 2s do LCAs for other reasons — for example, they may want to differentiate their products against other materials or against competitors’ products.”

“The value of LCA really exists in its ability to, as a manufacturer, model all of your variables and find the lowest impact solution,” Ollie Taylor, associate director at sustainability consulting firm Anthesis Group (London, U.K.), notes. “LCA isn’t purely about reporting. It’s much more about finding optimization and eco-design. It’s a decision support tool. The trouble with LCA is, of course, that it’s time-consuming. And it can be very complex.” Therefore, a number of tools are available today to simplify the process according to a company’s needs.

LCA Tools and Approaches

One option is to employ a third-party consulting firm, in which case consultants will work with the company to define goals and parameters for the project, collect needed data and use their preferred or in-house software and databases to generate an impact report.

If a company wants to learn more about its carbon footprint data directly, there are now numerous software applications available — ranging in complexity, cost and target industry — that companies can use to conduct an LCA themselves.

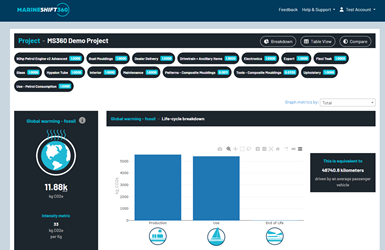

This demo project from MarineShift360 illustrates the way the tool breaks down GWP/CO2e for each component of a boat. Source | Anthesis

While not an exhaustive list, common LCA software platforms include expert-level tools like LCA for Experts (formerly known as GaBi), from software and consulting services company Sphera (Chicago, Illinois, U.S.); SimaPro, from PRé Sustainability (Amersfoort, Netherlands); and Umberto, from iPoint-systems GmbH (Hamburg, Germany). There are also free, simplified tools available such as openLCA, from GreenDelta (Berlin, Germany), and several industry-specific tools, such as the marine market’s MarineShift360, developed by Anthesis Group (London, U.K.) with 11th Hour Racing.

LCAs can be done through either a top-down or bottom-up approach. A faster, top-down LCA will rely on data readily available in databases. Databases generate carbon emissions calculations based on averages of data provided to the database creator by primary suppliers. Because the data is based on modeled averages and not the actual specific information from a product’s real-life supply chain, the generated carbon footprint information will be an estimate. Top-down approaches are ideal for early product design phases, when the materials and process are likely to change.

A bottom-up approach is more in-depth and more accurate, conducted when a product design and its processes and materials are selected. This type of LCA requires specific data from materials suppliers and Tier manufacturers.

Challenges and Potential

As additional research, regulations and tools continue to be developed, Anthesis Group’s Taylor cautions that understanding the reason behind conducting an LCA remains vital. “Because we don’t have one common way of doing LCA at a global level, companies can manipulate LCA results to support whatever case they want to make,” he says.

One way to combat using LCAs for data manipulation or greenwashing is increased data availability from suppliers. “As more companies publish data, the more accurate the numbers will be, and the more critical review we can have of what it all amounts to,” Taylor says. Common guidelines and legislation will also help, “but regulations are slow. I see legislation hitting people in the pocket in probably 10 years.”

On the other hand, using data through LCA work can also help determine whether a particular sustainability-related solution actually reduces the carbon footprint or not.

Ultimately, in an era where data and digitization in general are a growing focus for many manufacturers, LCA is another tool to use data specifically for achieving environmental and sustainability goals, and enabling that within their supply chains. Taylor adds, “If you don’t have the data, you’re shooting in the dark. LCA is a core tool that allows you to measure the data, simulate what can change and then set a path of travel that reduces your impact. In the last 2 years, there’s been much more awareness within our client base that they need to start doing this if they’re serious about reducing their impact on the world, and I think it’s only going to keep growing.”

More From This Author

Hannah Mason reports about the composites manufacturing industry for CompositesWorld and about sustainability in manufacturing for parent company Gardner Business Media.

Related Content

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreFilm Extrusion: Boost Mechanical Properties and Rate of Composting by Blending Amorphous PHA into PLA

A unique amorphous PHA has been shown to enhance the mechanical performance and accelerate the biodegradation of other compostable polymers PLA in blown film.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More