Film Extrusion: Boost Mechanical Properties and Rate of Composting by Blending Amorphous PHA into PLA

A unique amorphous PHA has been shown to enhance the mechanical performance and accelerate the biodegradation of other compostable polymers PLA in blown film.

Sustainability continues to be an increasingly important issue for processors and their customers. The term “sustainability” has many dimensions; however, for film processors, carbon footprint and waste (postconsumer) management are critical issues.

One family of polymers that can address both considerations are poly(hydroxyalkanoates) or PHAs. PHAs are bio-based and can be produced with a better carbon footprint compared to polyolefins. Further, the natural biodegradability of PHAs make them well suited for postconsumer plastic waste management challenges.

A remarkable discovery, dating back to 1926, documents the presence of thermoplastic polyesters within bacterial cells. The basic polyester that was isolated and characterized was poly (3-hydroxybutanoic acid) or P(3HB). It was later determined that the P(3HB) granules within the bacterial cells serve as an intracellular food and energy source. P(3HB) is an ideal carbon storage medium because it is inert to water, chemicals and osmosis, and can be readily converted to monomeric form through a series of enzymatic reactions.

Consequently, PHB copolymers and their products will biodegrade in soil, home compost and industrial compost environments; they will also biodegrade in fresh water and sea water environments. Because of their biobased content and broad biodegradability, PHB copolymers are receiving considerable attention for employment in various thermoplastics applications such as injection molding, extruded sheet, film (blown and cast) and extrusion coating.

CJ Biomaterials (a subsidiary of CJ CheilJedang) got into the biopolymer space by acquiring technology from Metabolix. CJ Biomaterials, or CJ BMS, commissioned the first production unit for PHA production in 2022. While CJ BMS has very broad microbial engineering capability to produce a variety of polymer compositions, the early industrial production focus is on copolymers of 3HB and 4HB (4-hydroxybutanoic acid). The first product from this production asset is a very unique PHA composition — it is an amorphous rubber with a sub-ambient glass transition temperature.

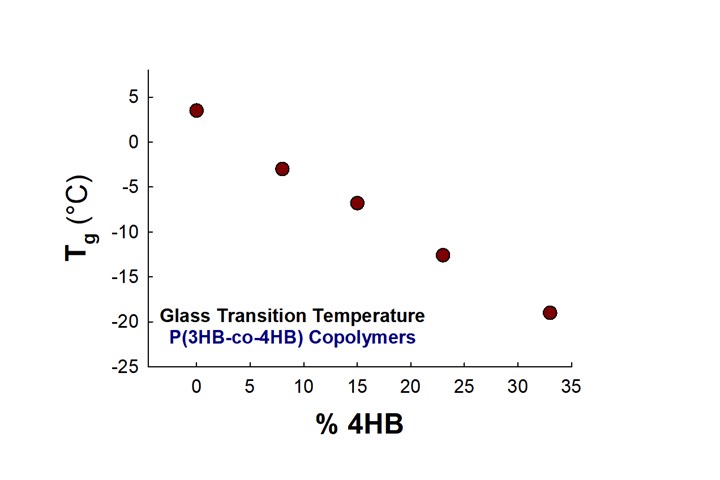

P(3HB) homopolymer is a highly crystalline (equilibrium crystallinity of 60-70%) thermoplastic with a melting point of ~+175 °C and a Tg of ~+3 °C. With the incorporation of 4HB into the backbone, the crystallizability of the 3HB sequences is disrupted. In other words, the crystallinity, Tg and melting point of the polymer decreases systematically with increasing amounts of 4HB in the backbone. The change in Tg with 4HB content in the backbone is shown in Figure 1. The first commercial product CJ BMS launched is an amorphous grade with a target 4HB composition of greater than 30%; this grade is branded as PHACT A1000P.

FIG 1 Glass transition temperature of P(3HB-co-4HB) copolymers as a function of 4HB content. The product highlighted is PHACT A1000P. Image Credits: CJ Biomaterials

A1000P is certified to be 100% biobased and industrially compostable, home compostable, soil biodegradable and marine biodegradable. The rubbery nature of A1000P enables it to be an excellent modifier to other biobased and compostable polymers such as PLA, PBS and PBAT.

Trials have revealed significant improvements in flexibility, impact toughness and rate of composting when amorphous PHA is blended into PLA. CJ BMS has entered into a strategic partnership with NatureWorks to further explore new market opportunities that unique blends of Ingeo PLA and PHACT A1000P can enable in several applications. In this article, we will focus on blown and cast film possibilities with such blends.

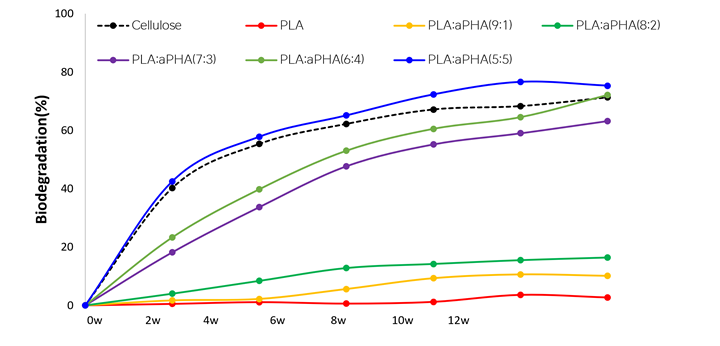

It is known that PLA is a biobased and industrially compostable polymer. Figure 2 shows biodegradation data (carbon conversion as a function of time at home compost conditions) for pure PLA as well as for blends of PLA and aPHA (A1000P). Samples of each ratio of PLA and aPHA were manufactured on a twin-screw extruder. This data shows clearly that these blends become home compostable at A1000P ratios that exceed 30% in a PLA/aPHA blend. In other words, PLA-rich compounds can be home compostable at sufficiently high concentrations of A1000P in the blend.

FIG 2 Biodegradation data, plotted as carbon conversion percentage as a function of time, in home compost conditions for various blends of PLA and aPHA.

Note that this is the result of an internal experiment conducted by lowering the temperature to ~30°C using the ISO 14855-1 modified method. Biodegradability tests were conducted using a respirometer. This opens up the opportunity to develop formulations that are both tough and flexible and home-compostable.

Mechanical Performance of Film

Let’s shift to processing and mechanical performance of blown films that are based on blends of Ingeo PLA and PHACT A1000P. The two products highlighted are CA1270P and CA1240PF. CA1270P is a transparent film product better suited for snack food packaging, while CA1240PF is an opaque product (mineral-filled) better applied for compost bag and organic waste diversion applications. Based on the observations presented in Figure 2, the products that we discuss will be tentatively deemed as “home compostable.”

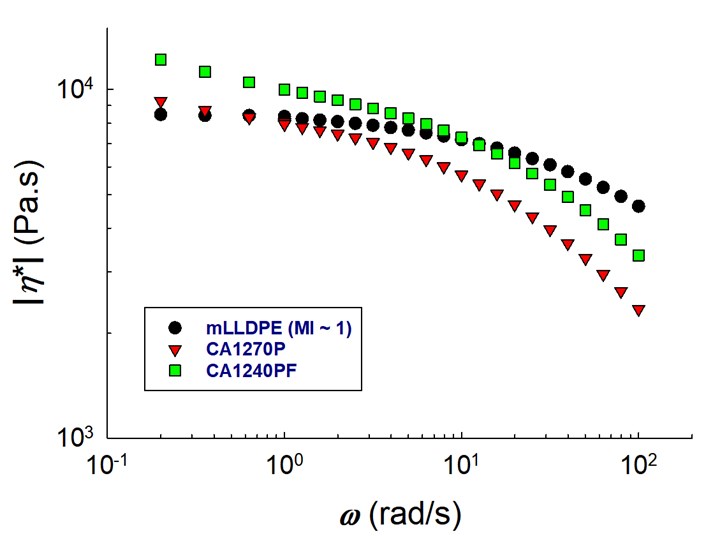

Figure 3 show the melt rheological attributes of CA1270P and CA1240PF. Data is shown relative to a metallocene-based LLDPE blown film product. From this figure, we judge that the melt rheological attributes of CA1270P and CA1240PF are sufficient for blown film processing. This has been verified on large commercial-scale processing operations for 20- to 50-µm thickness range. This is best accomplished using a low-stalk bubble configuration with a dual-lip air ring. Internal bubble cooling will also help to stabilize the film at high drawdown ratios. Both products have also been converted in cast film with similar success.

FIG 3 Torsional melt rheology data shown for CA1270P and CA1240PF, in comparison with a LLDPE blown film product.

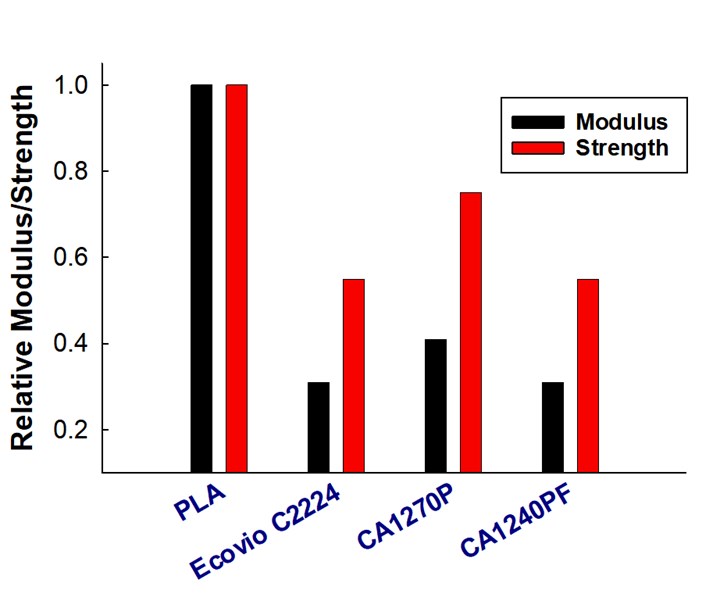

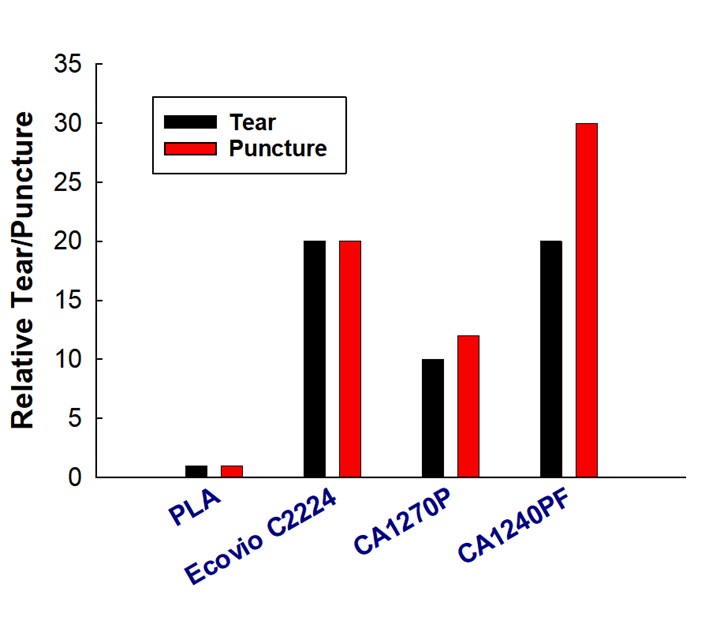

In Figures 4 (modulus & strength) and 5 (tear and puncture), we depict the relative blown film properties of the two products mentioned here (CA1270P and CA1240PF). The properties are listed relative to those of pure PLA blown film. Properties for the Ecovio C224 grade, obtained from a film product datasheet from the BASF website, are also included here for purposes of comparison. Ecovio grades are typically blends of PBAT with PLA; these are industrially compostable products that are partially biobased.

FIG 4 Properties (modulus and strength along the film MD) of CA1270P and CA1240PF blown films shown relative to those of a PLA blown film. Film properties of Ecovio C2224, from a published datasheet, are also included here for purposes of comparison.

From Figure 5, we see that incorporating A1000P into PLA decreases the modulus and strength relative to PLA while simultaneously improving flexibility. The modulus and strength of CA1270P blown film are considerably higher than those of the Ecovio grade, while the modulus and strength of CA1240PF films are similar to those of the Ecovio product.

FIG 5 Properties (film MD tear resistance and puncture toughness) of CA1270P and CA1240PF blown films shown relative to those of a PLA blown film. Film properties of Ecovio C2224, from a published datasheet, are also included here for purposes of comparison.

Incorporating A1000P into PLA results in a considerable improvement in the toughness of PLA blown films. We note dramatic improvements (greater than an order of magnitude) in tear propagation resistance, puncture toughness and tensile elongation relative to PLA. The tear resistance and puncture toughness of CA1270P blown films are slightly inferior to those of the Ecovio product, while the tear resistance and puncture toughness of CA1240PF blown films are similar to those of the Ecovio product.

We have also evaluated both products in blown-MDO (machine direction orientation) processing. The oriented CA1270P film showed excellent potential for shrink applications with shrink up to 50% achieved with 3X orientation. As expected, the oriented films display higher modulus and strength at the expense of tear propagation resistance. When CA1240PF was subjected to the blown-MDO process, presence of calcium carbonate in the product led to the creation of microvoids in the film. Density reduction of 20-25% can be easily achieved with this product.

It is clear that the packaging value chain will need to tailor their approaches to respond to an evolving and varied consumer landscape. A recent McKinsey global consumer survey indicated a strong consumer preference for compostable and biobased packaging solutions.

Amorphous PHA (PHACT A1000P) enhances the mechanical performance and accelerates the biodegradation of PLA. We are exploiting these new attributes in the form of two new products, CA1270P and CA1240PF, designed for flexible packaging and bag applications. These products are 100% biobased with an excellent balance between stiffness, strength, tear propagation resistance and puncture toughness. CA1270P enables the production of transparent films (haze ~3-5%), while CA1240PF films are opaque.

Both of these products have excellent potential to achieve home compostable certification. Both of these products are ideal candidates for snack food packaging, produce bags, frozen food bags, shopping bags and other flexible packaging applications, while CA1240PF films are best suited for organic waste diversion (small and large organic waste diversion bags). Oriented CA1270P films also showed strong potential for shrink wrap and label applications, while oriented CA1240PF films (with micro-voids) displayed potential for hygiene-backing film applications.

About the Authors: Raj Krishnaswamy is v.p. of polymers R&D at CJ Biomaterials. He had over 20 years of polymers R&D experience at Chevron Phillips Chemical, Metabolix and Braskem prior to his current stint at CJ. He is a co-inventor on 50-plus patents and a co-author on 40-plus publications. He is a Fellow of the Society of Plastics Engineering, has been recognized with the Research/Technology lifetime achievement award by the SPE, and is an alumnus of the NAE Frontiers of Engineering. Contact: 339-999-2693; cjbio.net; raj@krish.cj.net; cjbio.net.

Eunhye (Grace) Lee is the group manager of polymer application R&D at CJ Biomaterials. She has a Ph.D. in polymer engineering from Osaka University and over 10 years’ experience in research on biopolymers. In particular, she has led application studies on biopolymers such as PLA, PHA and PGA. She recently published several papers on the behavior of polymer properties and the use of biopolymers. Eunhye is conducting research on improving the physical properties of PHA biopolymers and compounds, including tuning rates of biodegradability. Contact: grace.lee@cj.net.

Related Content

Why Compression Ratio is Important

Compression ratios have been pretty much standardized over the years, based on what has typically worked before. But there are quite a few variables that must be considered in order to get the optimum performance from your screw.

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreHow Much L/D Do You Really Need?

Just like selecting the extruder size and drive combination, the L/D should be carefully evaluated.

Read MoreExtruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)