How to Know the True Value of Conformally Cooled Injection Molds

What’s the return on investing in a new mold with conformal cooling to boost productivity? Will it pay for itself? How soon? Here’s a case study on how to answer those questions.

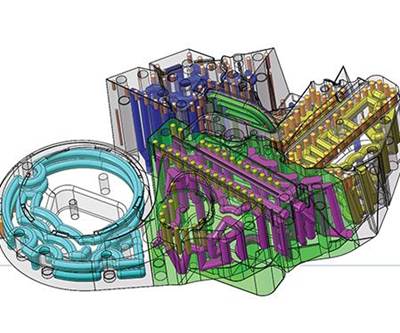

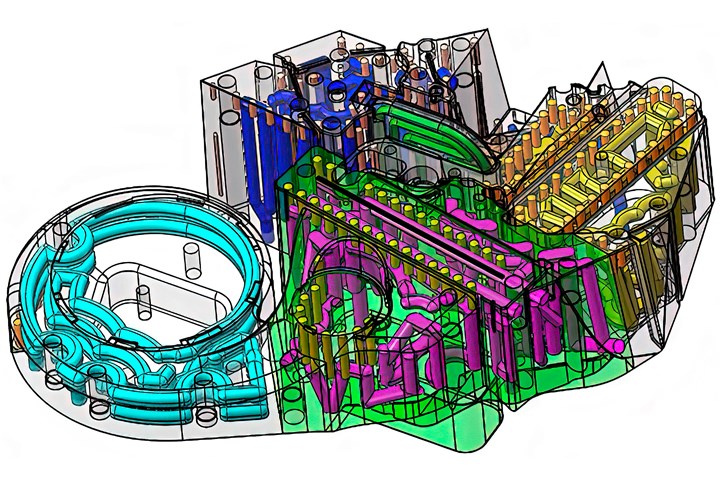

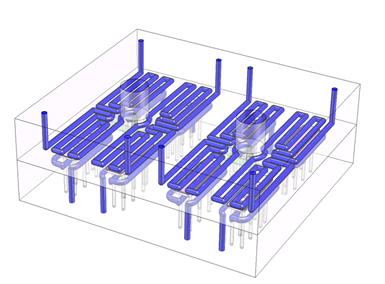

Conformal cooling wraps cooling channels around the part’s geometry to apply cooling wherever it is needed, unimpeded by complex part geometry. (Images: Contura MTC GmbH)

When evaluating cost-reduction projects in injection molding, the discussion typically centers around cycle-time reduction and the cost to implement the change. This article explores the true value of conformally cooled injection mold in a very specific case. That case is when the molder can sell more product than it can make on a 24/7 basis. In this pandemic environment, an illustrative example would be producing home COVID test kits (see photo).

What do you do if you could sell a lot more product than you can make with existing mold technology?

I chose this example because I see many companies struggling to meet the demand for so many healthcare-related plastic products like home test kits and lab testing supplies. I expect that high level of demand to go on for another three to five years. I believe conformal cooling can fill the product pipeline faster than any other technology.

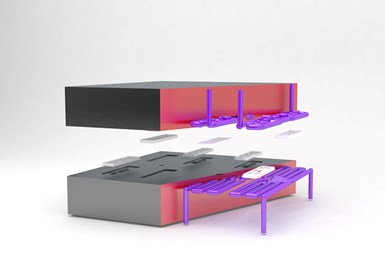

Conformal cooling, for in brief, utilizes cooling channels that curve and coil—in two or three dimensions—to conform as closely as possible to the contours of the part, thereby bringing more efficient heat removal than is possible with conventional gun-drilled straight cooling passages. The two main methods of producing such nonlinear cooling channels are additive manufacturing (3D printing) and vacuum brazing of stacked plates. (Learn more here.)

But despite the pressure to produce, so many companies are reluctant to try new technologies like conformal cooling or pay the approximately 20% upcharge in mold costs. To ease that transition, I developed this analysis to measure the return on investment (ROI) over the life of a conformal mold as a function of the increase in sales and profit that it enables. I’ll try to do this in a somewhat simplified fashion, for the sake of clarity, without getting “too deep into the weeds” of cost accounting.

Case History: COVID Test Kits

Generic design of a sample COVID test kit.

Let’s say this injection molded product has yearly sales of $1 million and a gross margin of 40%, or $400,000. You, the lucky molder, have demand for 35% more product, and that demand is continuing to grow, but the current mold is running 24/7 and is maxed out. To increase sales to accommodate the demand, you need to order a new mold to run in another press, or you can investigate replacing the current mold with one using conformal cooling to run in the existing press.

Generic example of a multicavity mold for COVID test kits, with conformal cooling.

A plant running 24/7 and 365 days a year typically operates at 85% to 90% efficiency, allowing for press and mold maintenance, etc. Running at 85% yields 7446 hr/yr (446,760 min/yr). Assuming a 27-sec cycle, you get 1 million cycles/yr.

Conformal cooling can reduce the cycle time by 30% to 40%. Assuming a 35% cycle improvement, the new cycle time would be 17.6 sec, producing 1,523,045 cycles/yr for a 52.3% increase in output. Remember that this was achieved without running a second mold in a second press, which avoided a huge additional cost.

Another view of generic mold for COVID test kits with conformal cooling.

Now, let’s look at the increased sales contribution. Your expanded output yields a 52% increase in sales and thus a 52% increase in gross profit.

Assume you started with a gross profit margin of 40% ($400,000). That is increased to 60% ($600,000) gross margin with the conformally cooled mold. The increase of $200,000 in gross margin goes directly into a $200,000 increase in gross profit.

Keep in mind that the 27-sec cycle with the original mold “paid all the bills”—namely, fixed costs and labor costs and resin costs (for the parts made with the 27-sec cycle). Presumably, there would be no additional labor cost with conformal cooling; since this is a high-volume molding operation, the press is already running without an operator and parts are taken away by a conveyor. The mold goes into the same press as before, so there is no increase in press rate. We’ll discuss the costs that do increase later.

What about conformal cooling’s contribution to cost reduction? Let’s start by asking what is the cost of conformal cooling when building a new mold. If a typical mold for this product would cost $100,000 (just to pick a round number), the conformal cooling would add approximately $20,000. Experience with conformal cooling shows that the typical range for payback of this additional investment is two to 12 months. Let’s assume a payback of six months. That means this new mold generates $20,000 cost reduction every six months, or $40,000/yr.

Existing technology can build a conformally cooled mold to last for 1 million to 5 million cycles. Let’s assume that the new mold runs for 3 yr, or 3 million cycles. During that period, the net cost reduction with conformal cooling—after payback of $20,000 in the first six months—is:

2.5 yr × $40,000/yr = $100,000.

Add this to the increased sales contribution to gross profit:

3 yr × $200,000/yr = $600,000

Thus, the conformally cooled mold increased gross profit by a total of $700,000. If you deduct the base cost of the new mold (not including the upcharge for conformal cooling, which has already been paid back), you are left with a handy $600,000 3-yr profit increase.

However, now we have to account for costs that increased due to molding 52% more parts. The most obvious is resin. Resin cost increased by 52%. Remember that the original 27-sec cycle generated a 40% ($400,000) gross profit margin. Let’s assume that “inside” that $400,000 is a resin cost of $100,000. We’re molding 52% more parts, using 52% more resin—which costs roughly $50,000 a year more—for a resin cost around $150,000 for the 3-yr life of the mold. This must be subtracted from the 3-yr saving of $600,000, for a 3-yr net saving of $450,000. Any cost incurred because of the production increase must be subtracted from the 3-yr savings.

Another potential deduction is electricity. The press is running 523,045 (52%) more cycles/yr. There are 52% more press openings and closings, as well as more heating and cooling required. The corresponding increase in electricity cost would need to be accounted for.

Also, the possible effect on power demand for a faster cycle would need to be determined. If the press could not support a faster cycle, higher-wattage barrel heaters could be considered. A more efficient injection screw, designed specifically for the resin being used, could be considered. A larger barrel and screw might even be in order.

Is it difficult to justify a modest tooling investment that increases production and profits and reduces costs?

‘Buyer Beware’

All technologies for building conformally cooled molds are not equal. In a high-volume example like the above, the buyer usually wants to run the mold for 2 yr or longer. We assumed a life of 3 yr for the mold in this example. Most of the technologies used to build a conformally cooled mold in the industry today cannot achieve a mold life of 2 million to 5 million cycles. The moldmakers that can achieve such a conformal mold life guarantee their cycle time and and warranty the life of the mold in millions of cycles. Look closely into the details of the guarantees and warranties.

Many large corporations in many industries are using conformal cooling technology. You will not see them advertising their cost benefits and profit gains, for obvious reasons. The type of financial analysis modeled here can by used by any corporation to justify a conformally cooled mold. It can also be used by any injection molder to present to a customer. In doing so, the molder demonstrates that it has the best interests of the customer in mind. It also demonstrates that the molder knows how to be the lowest-cost provider, which generates more business. Bottom line: This technology is a cash cow.

ABOUT THE AUTHOR

Robert Beard, P.E. is president of Robert A. Beard & Associates, Inc. and has over 40 years’ experience in plastics. His company provides technical and management expertise to the plastics industry, OEMs and the medical industry. He has been a turnaround general manager for a custom injection molding division, spent 10 years with Abbott Laboratories and was R&D manager for plastic coextrusion at National Can. He founded the Conformal Cooling Conference for Injection Molding, which was held in 2014, 2015 and 2017. Bob has taught thermodynamics, plastics, kinematics, advanced machine design and drafting at the Univ. of Wisconsin, Pennsylvania State Univ. and the State Univ. of N.Y. He is an Honored Fellow in the Society of Plastics Engineers and has been president of the Chicago and Philadelphia sections of SPE. Contact: info@plastic-solvers.com.

Related Content

Medical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

Read MoreAllegheny Performance Plastics to Enter Health Care Sector

The custom molder has secured multiple projects in health care and will be adding cleanroom and white-room spaces, as well as injection molding machines, in support.

Read MoreNew Cap for Child-Resistant Pill Bottles Is Senior-Friendly & Saves Resin

Exclusive lightweight cap design can be removed simply pushing down on the center. No gripping or twisting needed.

Read MoreUse Cavity Pressure Measurement to Simplify GMP-Compliant Medical Molding

Cavity-pressure monitoring describes precisely what’s taking place inside the mold, providing a transparent view of the conditions under which a part is created and ensuring conformance with GMP and ISO 13485 in medical injection molding.

Read MoreRead Next

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreWhy Conformal Cooling Makes $ense

Find out how this game-changing technology can make you more money but reducing cycles and cutting scrap.

Read More