Why Conformal Cooling Makes $ense

Find out how this game-changing technology can make you more money but reducing cycles and cutting scrap.

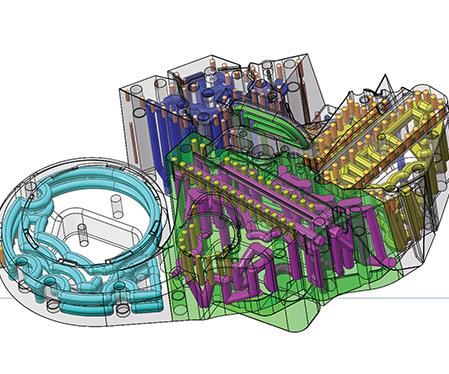

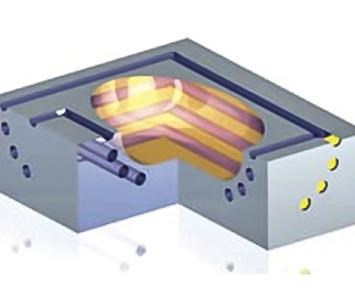

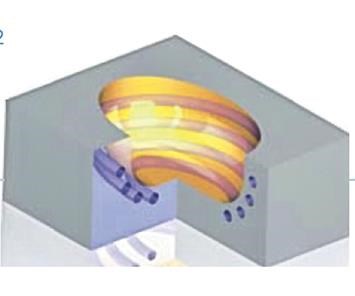

There has been a lot of talk among molders and moldmakers of late about conformal cooling. Why? Because it’s an industry game changer. Conventional molds have straight-line cooling channels (Fig.1). Simply put, conformal cooling makes use of cooling lines in an injection mold that curve and closely follow the geometry of the part to be produced (Fig.2). There are a variety of methods for manufacturing a conformally cooled mold, including laser sintering, vacuum brazing, liquid interface diffusion, and others.

If conformal cooling is implemented with little or no engineering analysis, you can expect to get a 10% reduction in injection mold cycle time. However, by performing more engineering analysis—such as flow analysis, computational fluid dynamics (CFD), and finite-element analysis (FEA)—a better quality mold and more cycle reduction can be achieved.

A typical cycle-time reduction range for a properly engineered, conformally cooled mold is 20% to 40%. If little or no engineering analysis is done, you risk premature mold failure or lack of performance because of poor design elements or incorrect assumptions that were not identified and corrected before mold manufacture.

Vacuum-brazing technology produces the largest conformally cooled production molds. Large molds for automotive parts and housings have been made by this process. The figure above is an example of the design complexity that has been successfully achieved in vacuum-brazed molds built by Contura MTH GmbH in Germany. Depending on the application, Contura will guarantee the life of the tool for 1 million cycles (SPI’s definition of a Class 101 mold).

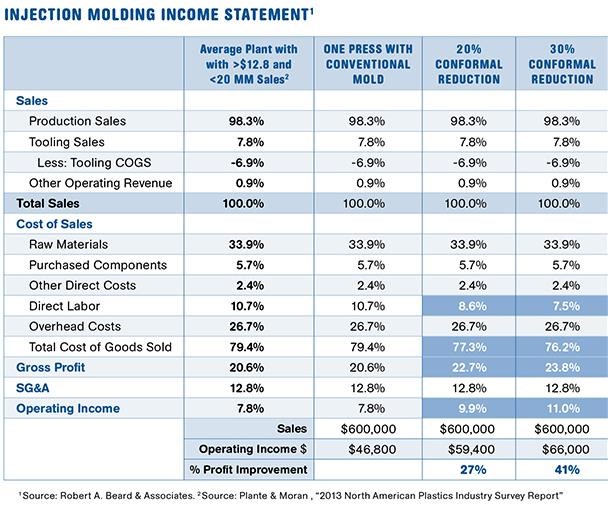

INCOME ANALYSIS FOR CONFORMAL COOLING

The accompanying income statement, which is based on a ratio analysis, was published by Plante Moran in its 2013 North American Plastics Industry Survey Report. It can be used to illustrate the effects of conformal cooling. I have amended the chart with additional columns and data. For example, since most molds are conventional molds (without the use of conformal cooling), Column 2 uses the same ratios as seen in Column 1. Columns 3, 4 and 5 show the estimated effect on profitability with a 20%, 30% and 40% cycle reduction from the use of conformal cooling on a single molding press.

To simplify the analysis, let’s look at a mold that is in the press 100% of the time and generates $600,000 per year in sales. A conventional mold would generate an operating income of $46,800. A conformally cooled mold would generate:

•@ 20% cycle reduction = $59,400 operating income (27% profit improvement).

•@ 30% cycle reduction = $66,000 operating income (41% profit improvement).

•@ 40% cycle reduction = $72,600 operating income (55% profit improvement).

In this analysis, the engineering analyses and the incremental cost to manufacture a conformal mold versus a conventional mold would be paid for by the “Operating Income $” increases.

Your income statement will most likely vary from the chart. You may want to add more line items for more definition.

To evaluate different scenarios, change the “sales” amount near the bottom of the chart and then multiply that amount by the “operating income” percentage (above in the same column) to change the “operating income dollars.” This is an analytic method that can be used to see the effect on one mold, one press, or an entire plant. This analysis does not take the place of a detailed estimate or quote, however. This analysis is conservative because it looks only at “Direct Labor” and not any other factors that might be improved.

The uniform cooling of the mold provided by conformal cooling will decrease rejects due to such issues as warping. Any reduction in reject cost will fall directly into profits. For example, the elimination of each 1% in reject rate would add an additional 1% to profits. In this analysis, the cost of the engineering analyses and the incremental cost to manufacture a conformal mold must be factored into an ROI calculation versus a conventional mold.

Conformal cooling is a tool to help decrease rejects, which reduces the risk of a costly recall. Because conformal cooling yields uniform part cooling, molded-in stress can be reduced. This produces a stronger part, which increases part safety, mitigating part-failure and recall risk.

Therefore, the decision to use conformal cooling should be an easy one for automotive and medical applications, or any application with a high risk of product liability. The cost of a recall is much more than the incremental cost of a conformally cooled mold.

FREEING UP ADDITIONAL PRESS CAPACITY

Another consideration is the availability of increased press capacity due to the productivity increases afforded by conformal cooling. To keep the math simple, let’s examine a 10-press plant using the same data as for a single press in the accompanying income statement. If a 30% cycle reduction is achieved plantwide, there will be three empty presses on the floor. Assuming that the presses are the same size as the press in the income statement, then there will be an increase in sales of $600,000 per year for each of the three presses, a total of $1.8 million, producing an additional $198,180 in annual operating income (at 11% operating income, according to the income statement). This might also cause an over-absorption of overhead, which would yield even higher profit.

According to the income statement, a 30% cycle reduction increases operating income by 41%. This gives you options. If you don’t have any competition, you can keep all the profit. Or you can keep half of the increase and use the other half to lower your prices to gain more business to fill up those three empty presses. Or you can sell the three presses to free up capital for investment.

It seems that when a company finds and installs new cost-saving technology, it keeps it a secret. So it might be wise to assume that, if your competition is quoting lower prices, it may already be using conformal cooling.

Related Content

A Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreRevisiting the '5 M's' of Molding

All injection molding ultimately comes down to the “Man, Mold, Machine, Material and Method.” But those key aspects can be viewed differently if you’re auditing mold changes before startup or troubleshooting changes for an already validated process.

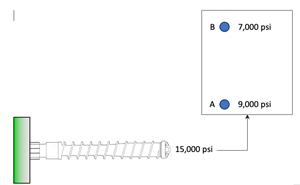

Read MoreUnderstanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

Read MoreMoving Beyond the Relative Viscosity Curve — Determining Optimum Plastic Flow Rates: Part 1

Should injection molders consider using a range of plastic flow rates, versus the selection of one plastic flow rate from the relative viscosity curve?

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More